Die for preparing large-size tubular green bodies through gel casting

A gel injection molding, large-scale technology, used in die-casting molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of uneven drying, cracking, and inconvenient demoulding operation of green bodies, and avoid shrinkage and extrusion cracking. , The effect of uniform drying and easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

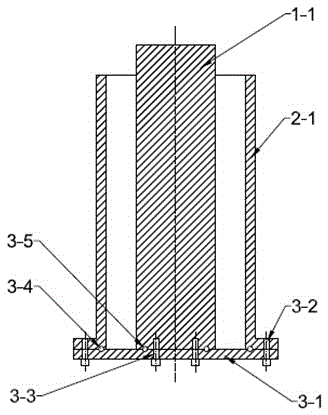

[0030] Such as figure 1 As shown, the mold for preparing a large-sized tubular green body by gel injection molding according to the first embodiment of the present invention mainly includes three parts: a chassis 3-1, an outer mold 2-1, and an inner core 1-1.

[0031] In this embodiment, the outer mold 2-1 is placed on the chassis 3-1, and the outside of the bottom of the outer mold 2-1 is provided with a convex edge, and the convex edge is provided with a plurality of mounting holes along the circumference, and is fixed on the On the chassis 3-1, there is an outer mold sealing ring 3-4 on the contact surface to ensure no liquid leakage. The inner core 1-1 is fixed on the center of the chassis 3-1, and the contact surface has an inner core sealing ring 3-5, and the inner core 1-1 and the chassis 3-1 are fixed by fastening bolts 3-3 to ensure no leakage.

[0032] Wherein, the outer mold 2-1 has a cylindrical inner cavity, and the inner core 1-1 is located in the inner cavity o...

Embodiment 2

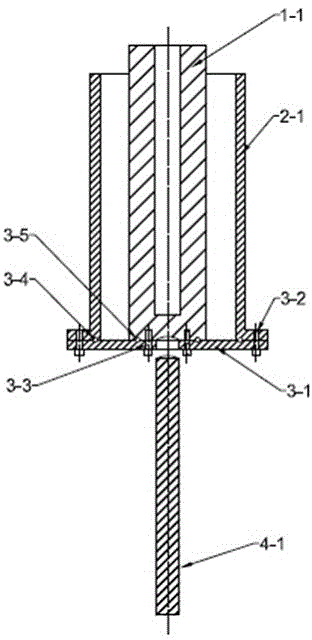

[0038] Such as figure 2 As shown, the mold for preparing a large-size tubular green body by gel injection molding according to another embodiment of the present invention includes a chassis 3-1, an outer mold 2-1, an inner core 1-1, and an ejection mechanism on the chassis . to combine figure 2 As shown, the ejection mechanism includes a guide hole in the center of the chassis 3-1, and a ejection hammer 4-1. The guide hole is located on the chassis 3-1 corresponding to the inner core 1-1, and the ejection hammer 4 -1 can pass through the guide hole for the ejection of the inner core 1-1.

[0039] In addition, the surface of the ejection ram 4-1 can also be provided with an external thread, which can be rotatably mounted on the chassis 3-1, and the guide hole at the center of the chassis 3-1 is provided with an inner thread that matches the external thread on the surface of the ejection ram. Thread, when the green body is dried for a certain period of time, the inner core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com