Latch PVC floor grooving device

A floor and lock technology, applied in the field of machinery, can solve the problems of affecting the position of slotting, increasing production costs, and many processing procedures, so as to achieve the effect of convenient slotting and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

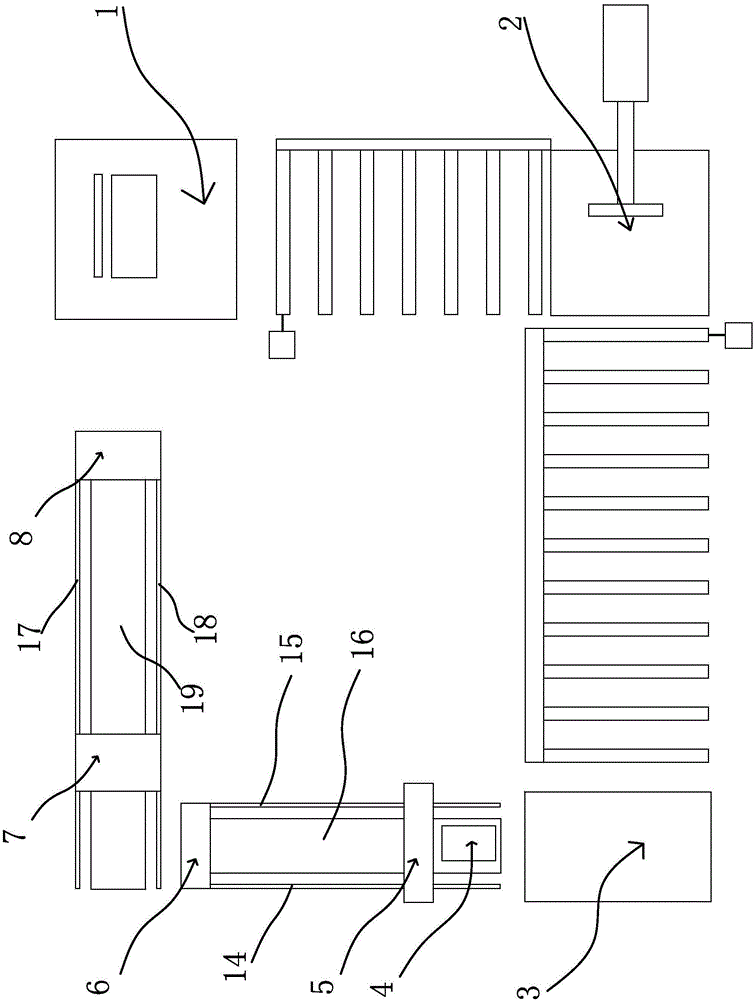

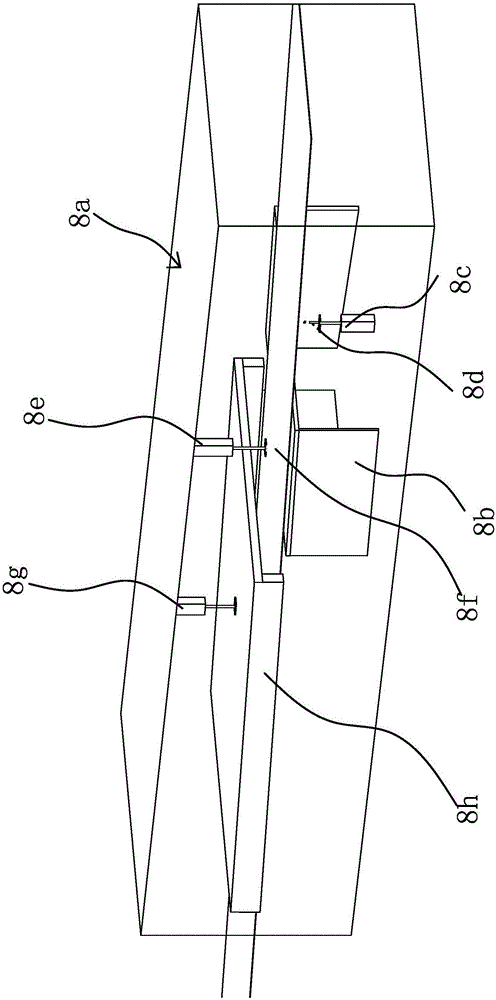

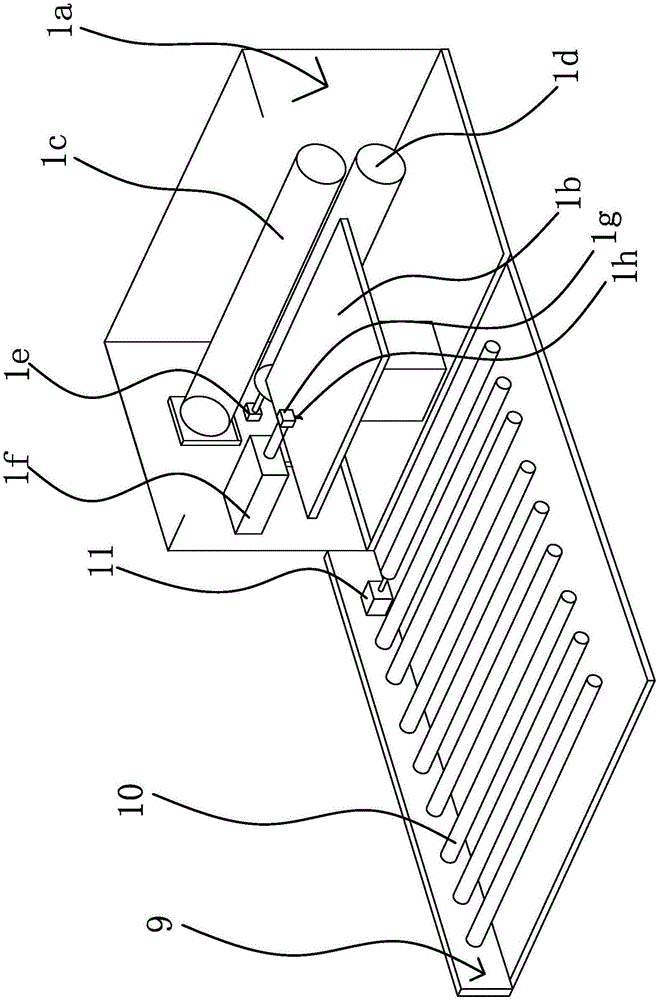

[0033] like figure 1 As shown, a processing equipment for locking type PVC flooring includes a frame 9, and one end of the frame 9 is provided with a cutting mechanism 1 capable of cutting PVC sheets into several PVC floors, such as figure 2 As shown, the slitting mechanism 1 includes a cutting bin 1a, a cutting table 1b, an upper pinch roller 1c and a lower pinch roller 1d, and the cutting bin 1a and the cutting table 1b are all fixed on the frame 9 using bolts, and the cutting table 1b, The upper pinch roller 1c and the lower pinch roller 1d are both in the cutting chamber 1a, the upper pinch roller 1c is installed on the frame 9 through the bearing seat 1 and the bearing seat 2, and the lower pinch roller 1d passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com