Connection terminal frame and flame-proof equipment

A connection terminal and explosion-proof technology, which is applied in the direction of connection, conductive connection, fixed/insulated contact components, etc., can solve the problems that the potting structure cannot meet the explosion-proof requirements of explosion-proof equipment, and achieve improved explosion-proof reliability and good insulation explosive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following descriptions of various embodiments of the present invention are merely exemplary, and in no way limit the present invention and its application or use. The same reference numerals are used to denote the same components in the respective drawings, and therefore, the configurations of the same components will not be described repeatedly.

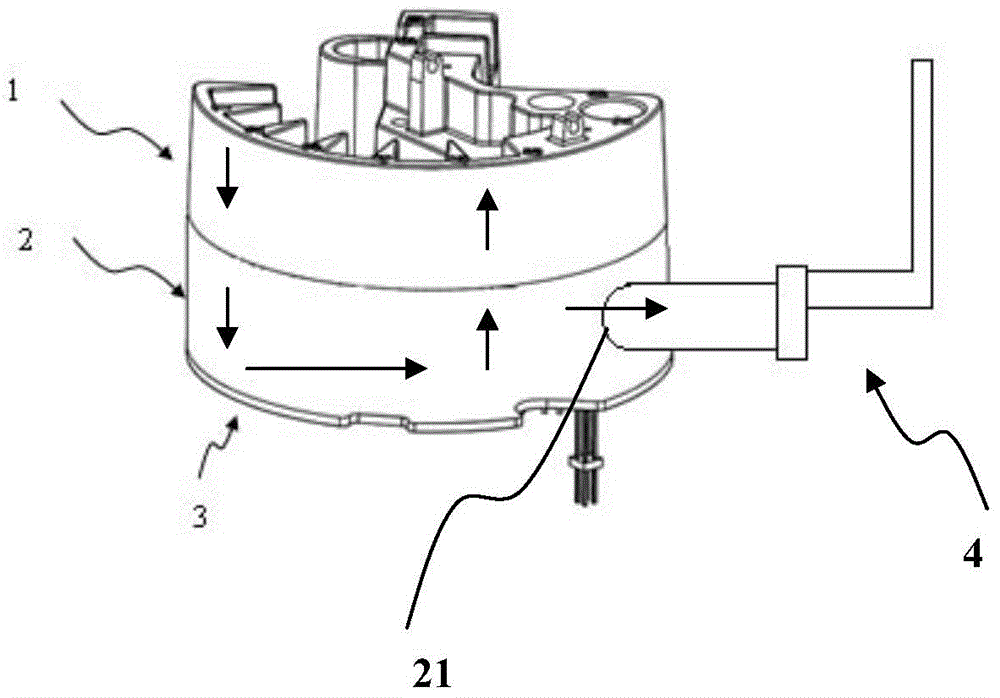

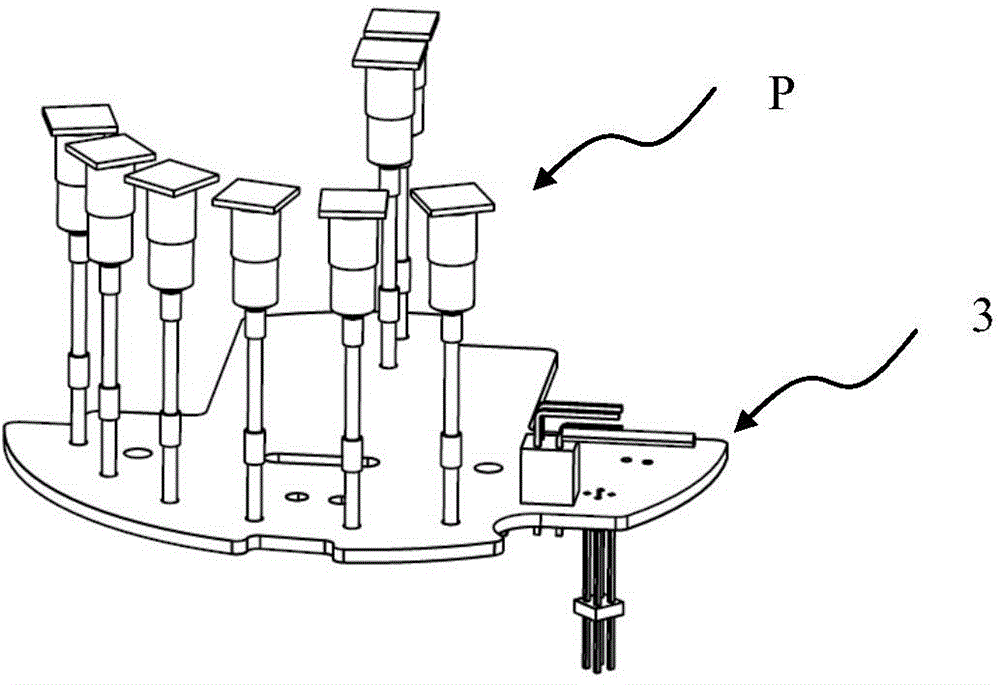

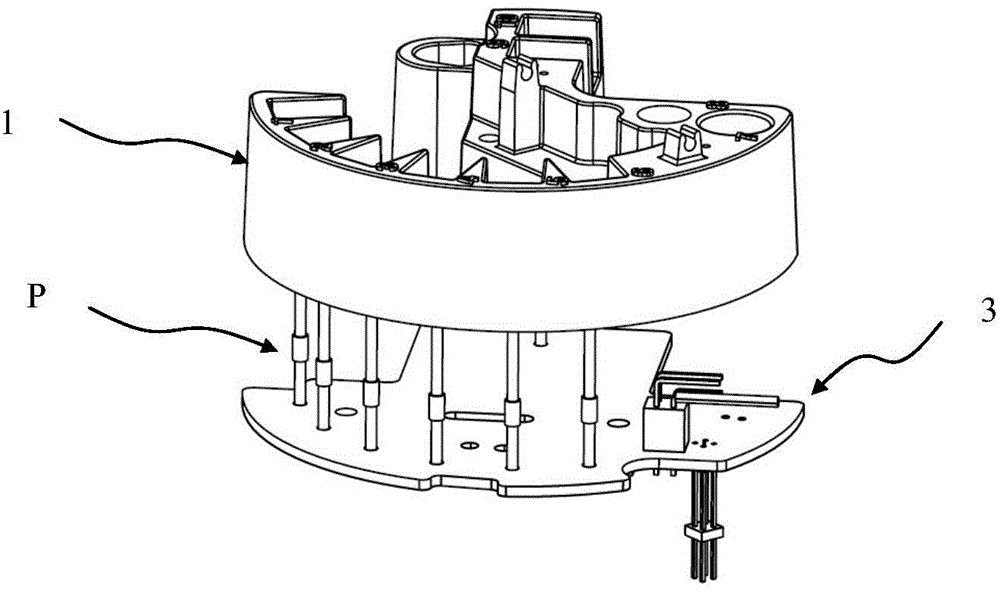

[0041] As mentioned earlier, for flameproof equipment, the terminal block plays the role of connecting external cables and electronic devices inside the flameproof equipment on the one hand, and on the other hand, it is used to connect the joint surfaces of related components. The potting material is poured into the gap between the explosion-proof equipment to realize the isolation of the electronic devices inside the explosion-proof equipment and the external environment of the explosion-proof equipment, and play the role of explosion-proof.

[0042] Such as Figure 1-Figure 3 As shown, the terminal block according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com