Novel aeroelastic model for wind tunnel test of power transmission tower structure

A technology of wind tunnel experiment and aeroelastic model, which is applied in the testing of machine/structural components, aerodynamic testing, measuring devices, etc., which can solve the problem of similarity, failure to satisfy the structure prototype of transmission tower, and the geometry of transmission tower structure prototype. Problems such as similarity and similarity in mass distribution achieve the effect of simple manufacturing process and convenient research on wind load characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further specifically described below in conjunction with the accompanying drawings and embodiments.

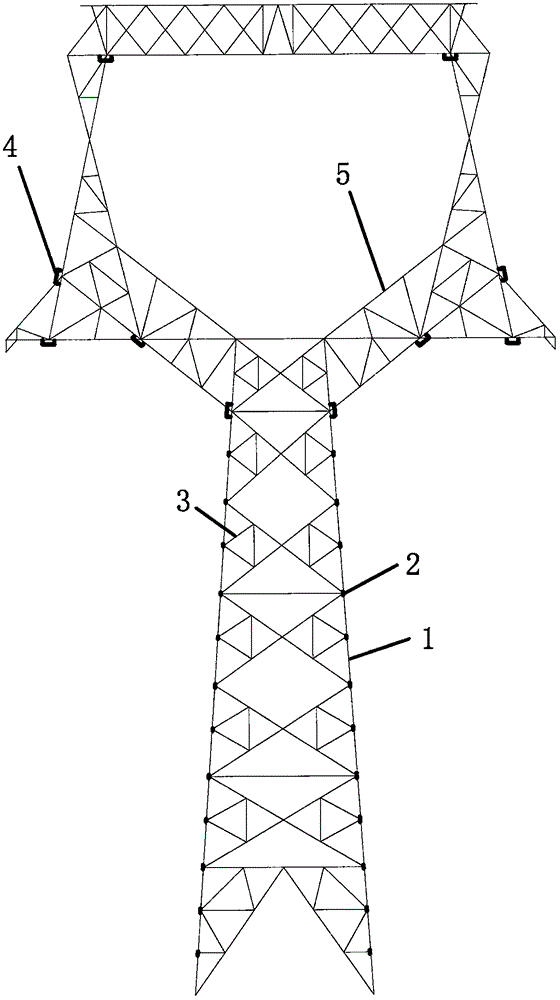

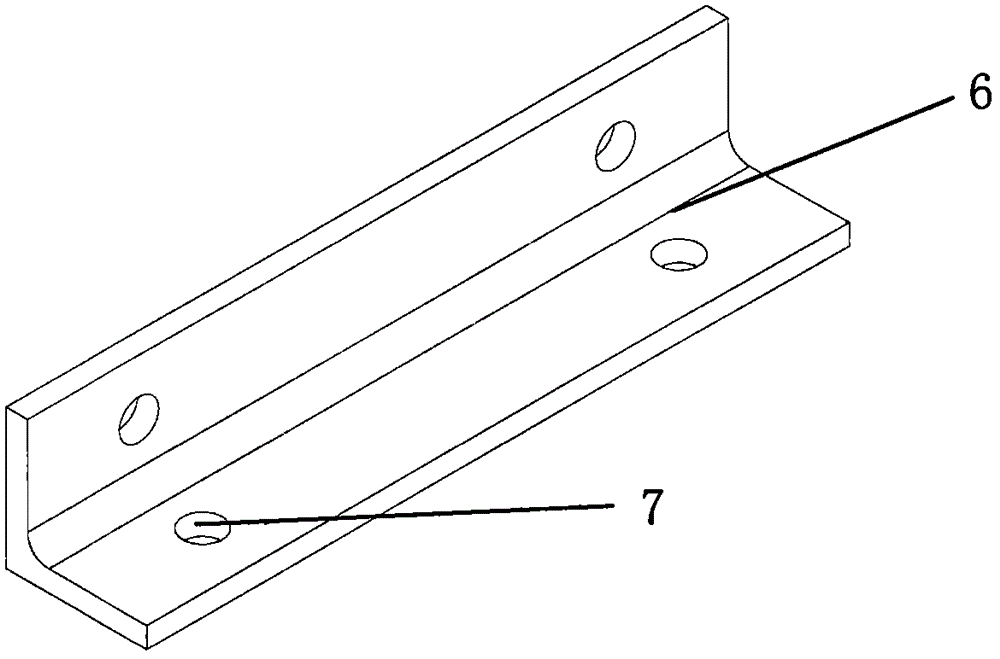

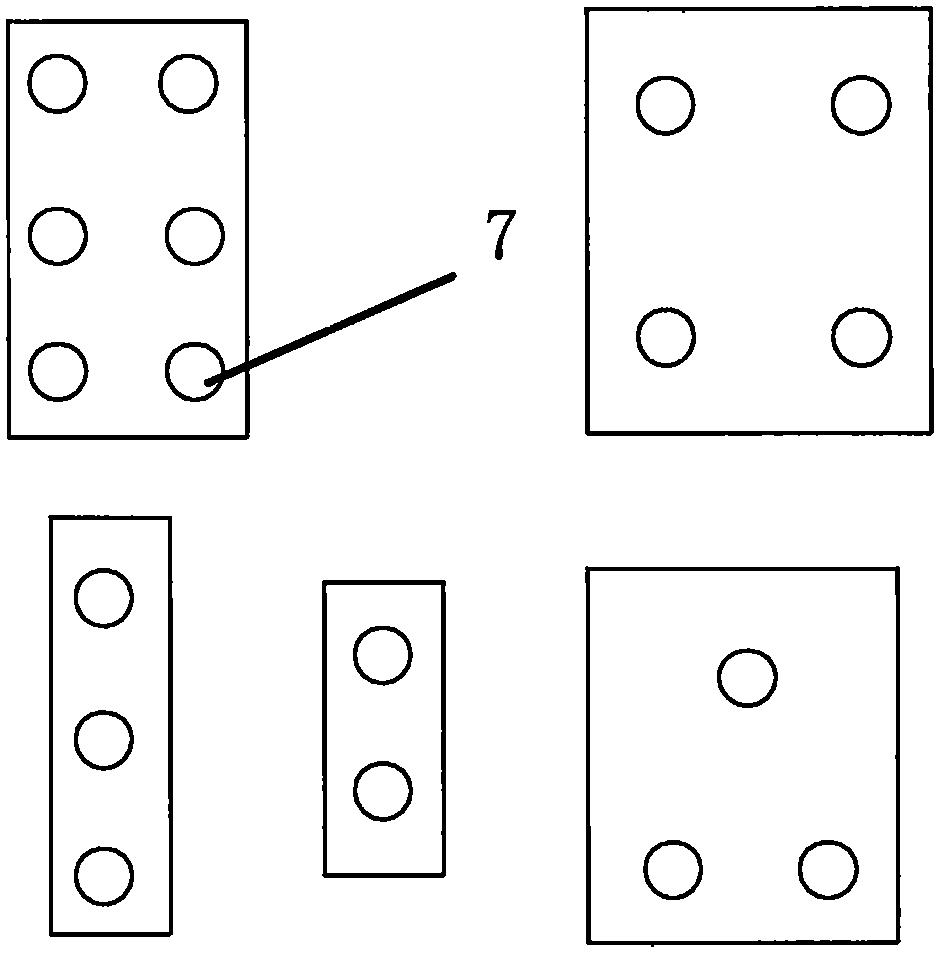

[0018] Such as figure 1 The aeroelastic model of a new type of transmission tower structure wind tunnel experiment of the present invention is shown, comprising: curved arm (5), angle steel section (3), n-type spring piece (4), copper wire (6) and tower frame Skeleton body (1); the tower frame body (1) is formed by connecting angle steel-shaped aluminum sections (3) through bolts (7) processed according to geometric similarity; crank arm (5) is made of angle steel The aluminum material segments (3) are formed by connecting (4) through n-type spring pieces, and metal wires (6) for counterweight are arranged inside the angle steel-type segments.

[0019] The aeroelastic model skeleton body (1) of the transmission tower is composed of angle-steel-shaped aluminum sections (3) connected by bolts (7) of different cross-sectional sizes and length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com