Process variable measurement and local display with multiple ranges

A process variable, range technology, applied in the direction of the indication of the measured value, the indication of the measured value, the measurement of heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

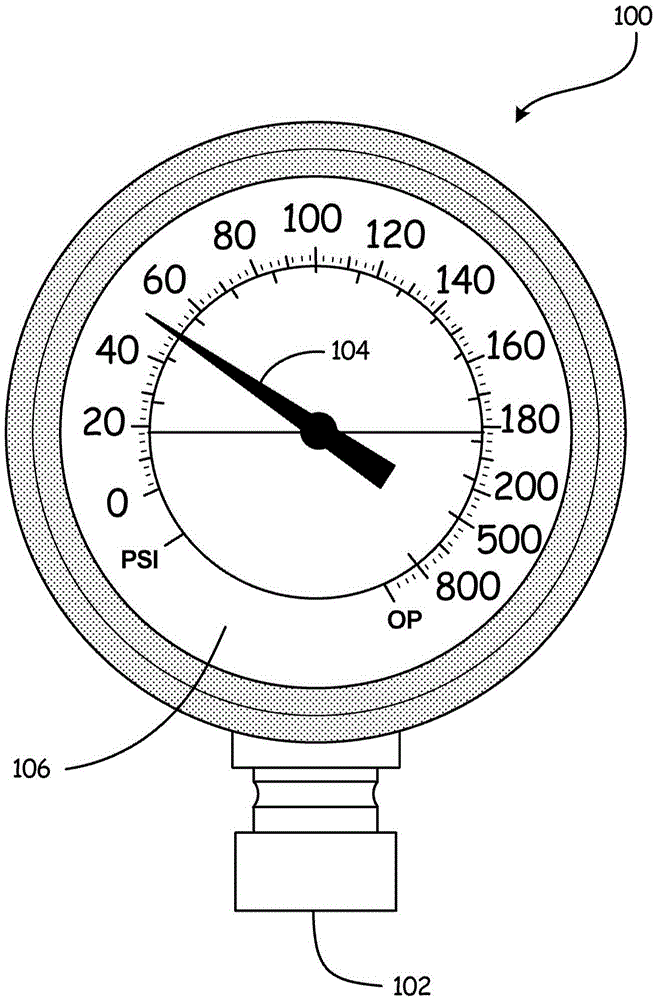

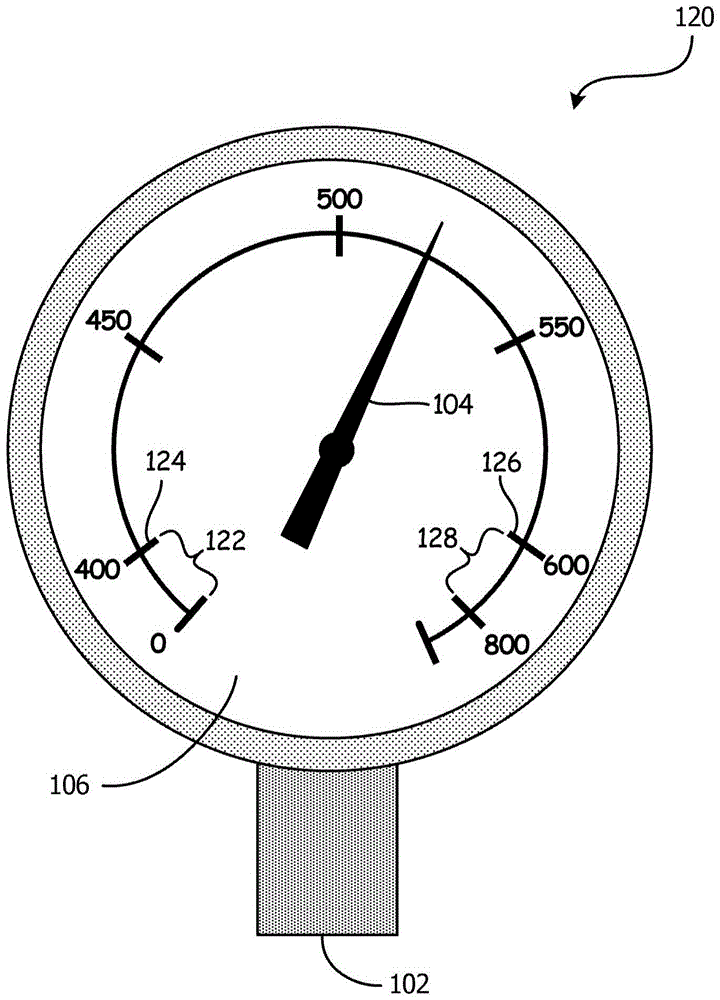

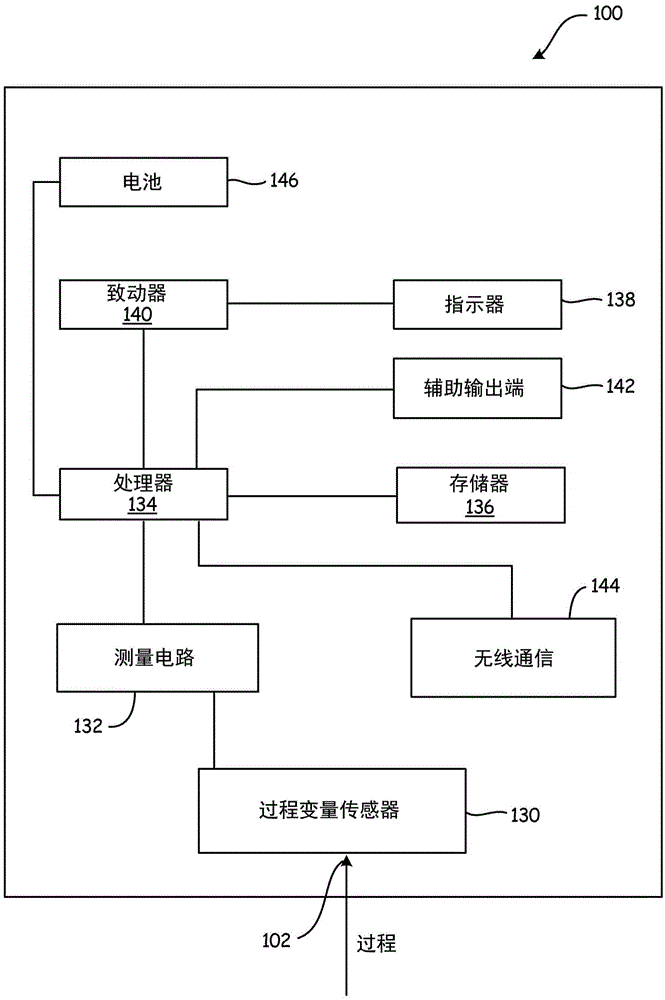

[0013] Measurement and display technologies for mechanical process variables are often limited in their ability to provide any features beyond their core functionality. Conversely, new process devices using electronic components can offer many new features compared to their mechanical equivalents. According to an embodiment of the present invention, a process variable sensing component provided for sensing a process variable with a process variable display device may have a sensing range of the process variable that is substantially in excess of the range desired by the end user. For example, a user ordering a device capable of sensing pressures between 0 and 200 psi may receive a pressure measuring capsule or part capable of accurately sensing pressures between 0 and 800 psi simply because the pressure measuring capsule or The component is the most suitable sensing device for the specified range. However, end-user requirements for an operating range between 0 and 200 psi wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com