Method for reducing mine loss dilution through differentiation charge structure control blasting

A technology with structural control and differentiation, applied in blasting and other directions, can solve the problems of dilution, waste of mine resources, and increase of beneficiation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

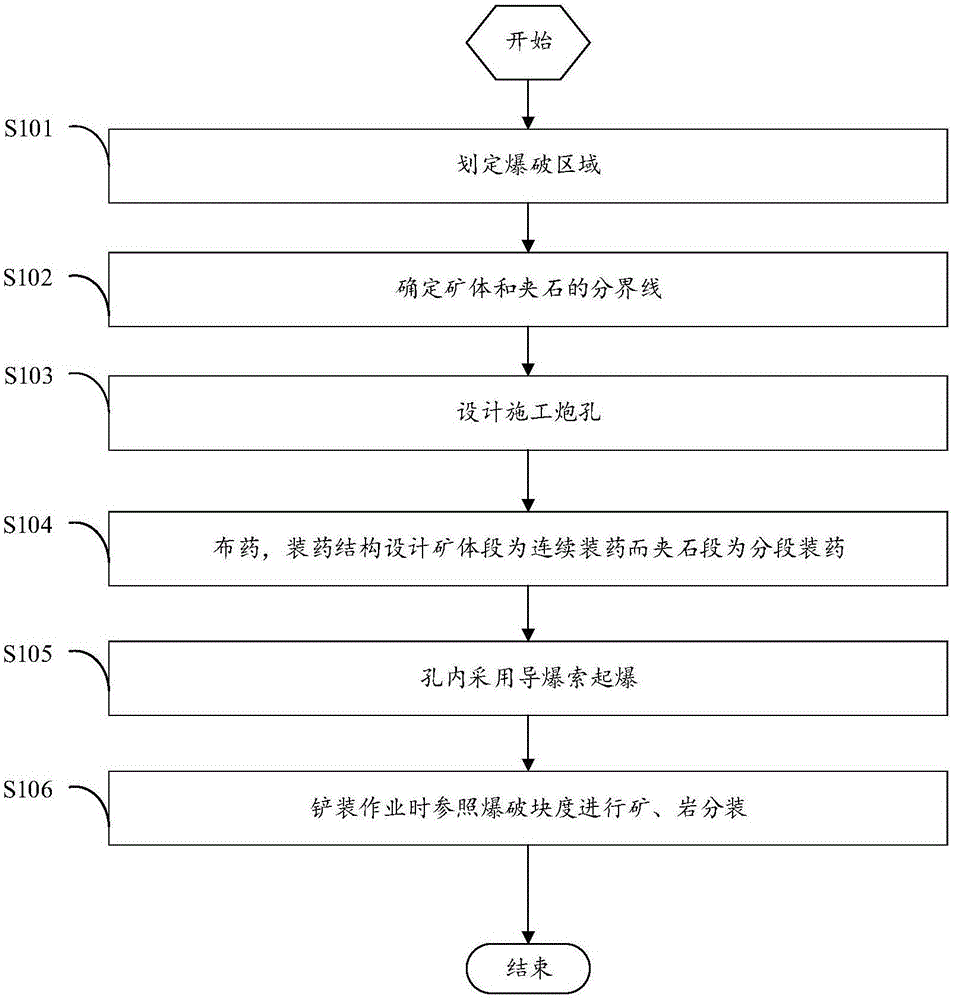

[0028] This embodiment provides a method for controlling blasting with differential charge structure to reduce loss and depletion. The technical solution includes the following steps:

[0029] Step S101: Delineate the blasting area;

[0030] Step S102: Determine the boundary line between the ore body and the interlayer;

[0031] Step S103: designing and constructing blastholes;

[0032] Step S104: distributing charges, charge structure design ore body section is continuous charge and stone interleaving section is stage charge;

[0033] Step S105: using a detonating cord to detonate in the hole;

[0034] Step S106: During the shovel loading operation, separate the ore and rock according to the size of the blasting block.

[0035] The demarcated blasting area is below the ground line 7, and the demarcated boundary between the ore body 1 and the rock 2 is clearly divided into different areas in the vertical distribution of the ore body 1 and the rock 2.

[0036] The blast hol...

Embodiment 2

[0042] This embodiment provides a method for controlling blasting with differential charge structure to reduce loss and depletion. The technical solution includes the following steps:

[0043] Step S101: Delineate the blasting area;

[0044] Step S102: Determine the boundary line between the ore body and the interlayer;

[0045] Step S103: designing and constructing blastholes;

[0046] Step S104: distributing charges, charge structure design ore body section is continuous charge and stone interleaving section is stage charge;

[0047] Step S105: using a detonating cord to detonate in the hole;

[0048] Step S106: During the shovel loading operation, the high-grade ore and the low-grade ore are subpackaged according to the blasting lumpiness.

[0049] The demarcated blasting area is below the ground line 7, the demarcated boundary between the high-grade ore body 1 and the low-grade ore body 2, and the demarcation line clearly separates the high-grade ore body 1 and the low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com