Continuous circulation drilling active sealing type rotation control head and screw-on-off method thereof

A rotary control head, active sealing technology, used in sealing/isolation, earthmoving, wellbore/well components, etc., can solve the problems of unreasonable design, low rubber core opening efficiency, large volume, etc. Simple and novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

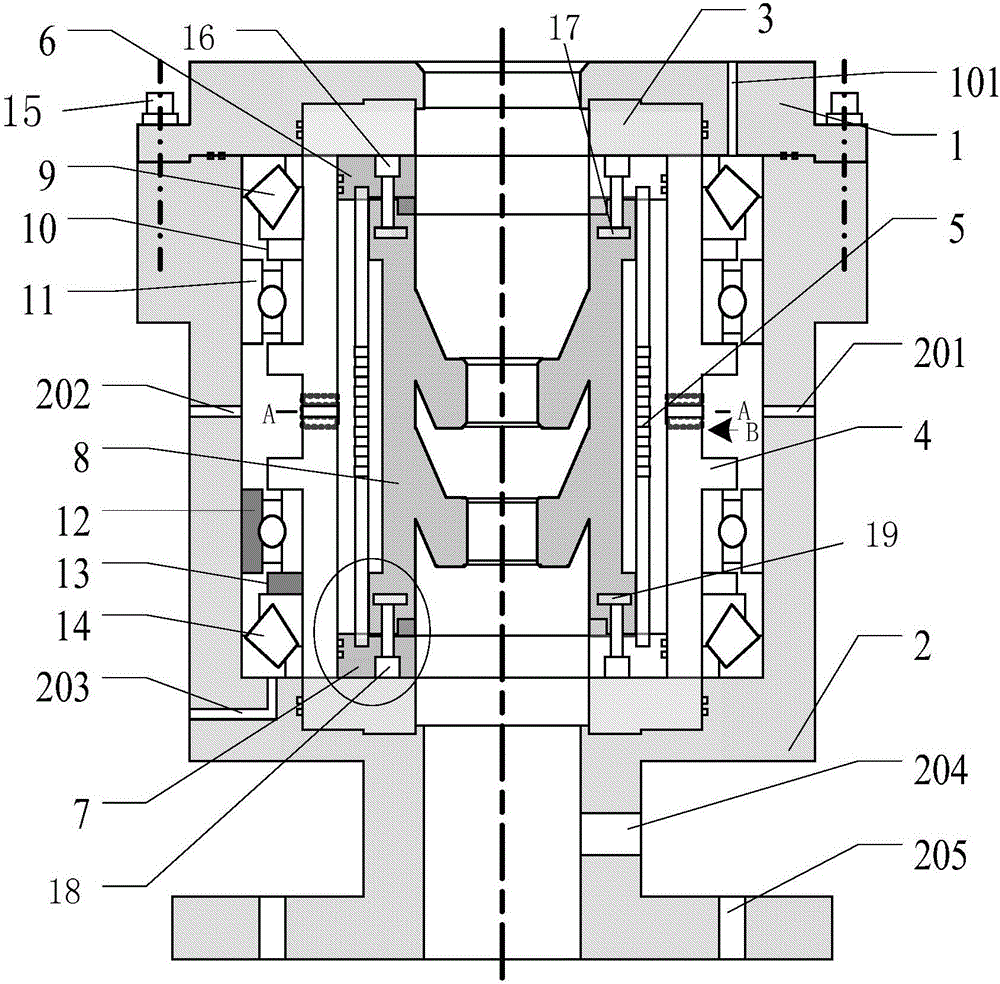

[0029] Such as figure 1 As shown, the active sealing rotary control head for continuous circulation drilling includes a rotating cylinder, a rubber core support cylinder 5, an upper rubber core pressure plate 6, a lower rubber core pressure plate 7 and a rubber core cylinder 8 arranged in a housing; wherein, The rotating cylinder, the rubber support cylinder 5 and the rubber core cylinder 8 are sequentially fitted from the outside to the inside; specifically:

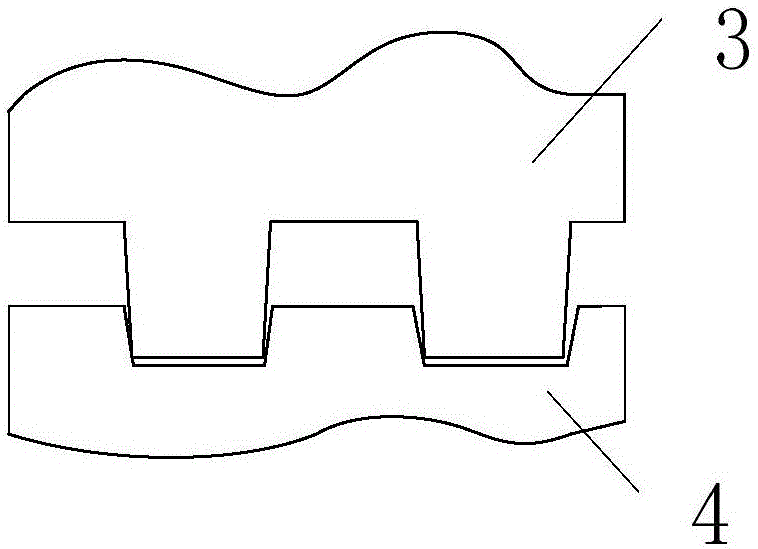

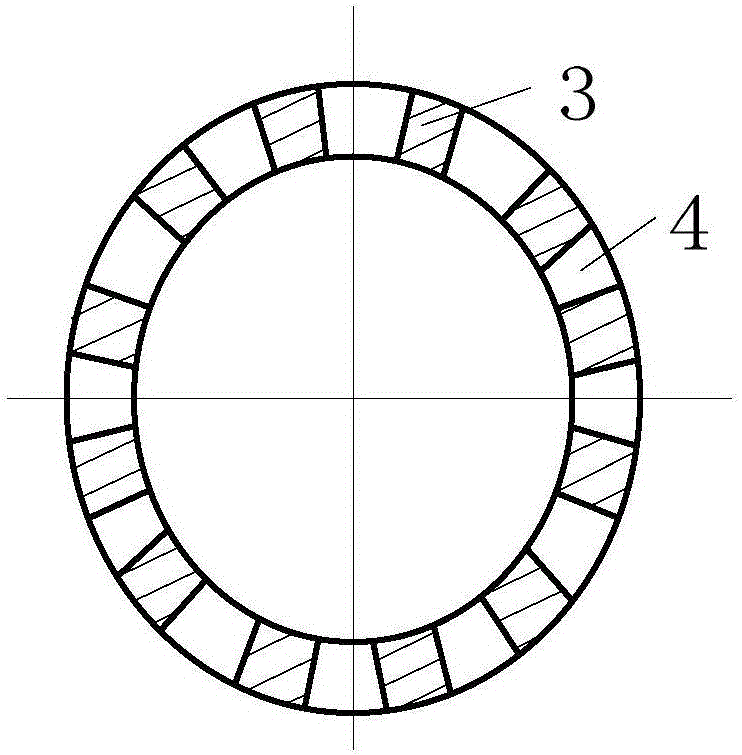

[0030] Such as Figure 2-4 As shown, the rotating cylinder includes an upper rotating sleeve 3 and a lower rotating sleeve 4; the bottom end surface of the upper rotating sleeve 3 is provided with a plurality of first protrusions arranged at intervals along the circumferential direction. The top end surface of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com