Wall pipeline grooving machine

A technology for slotting machines and pipelines, which is applied in the directions of construction and building structure, can solve the problems of difficult production and processing, shallow depth of pipeline grooves, and complicated structure of guide rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

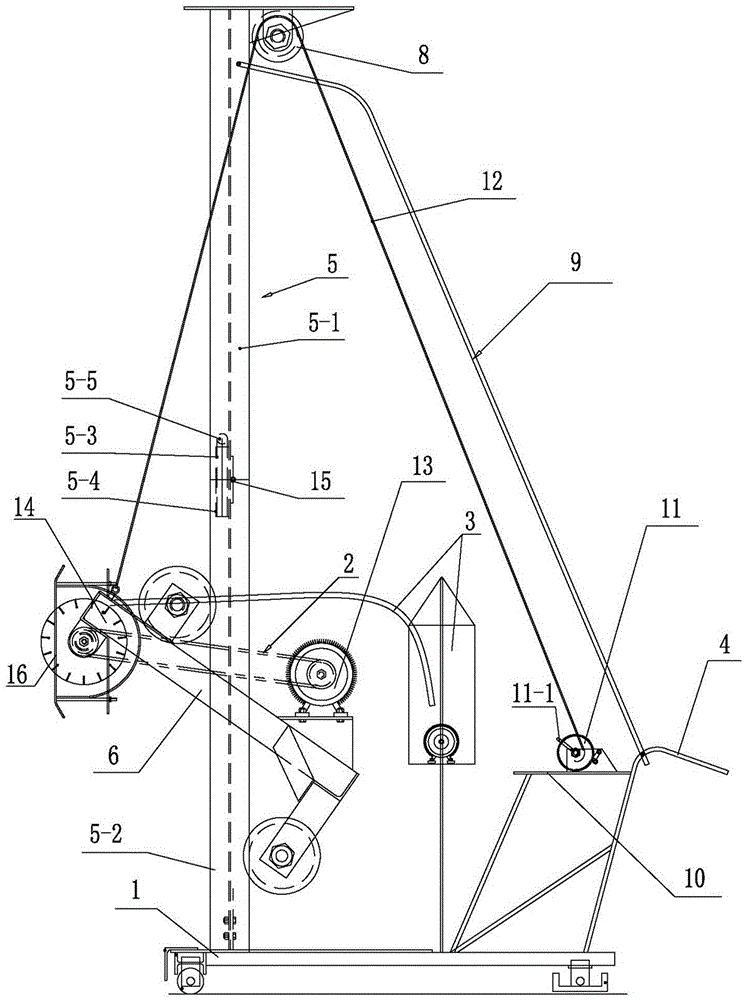

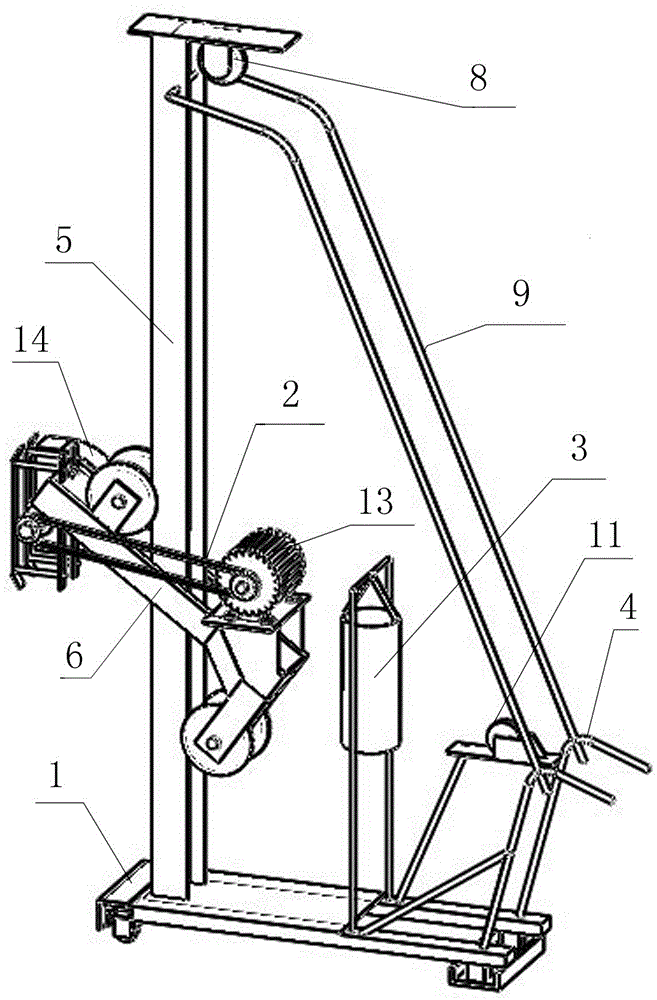

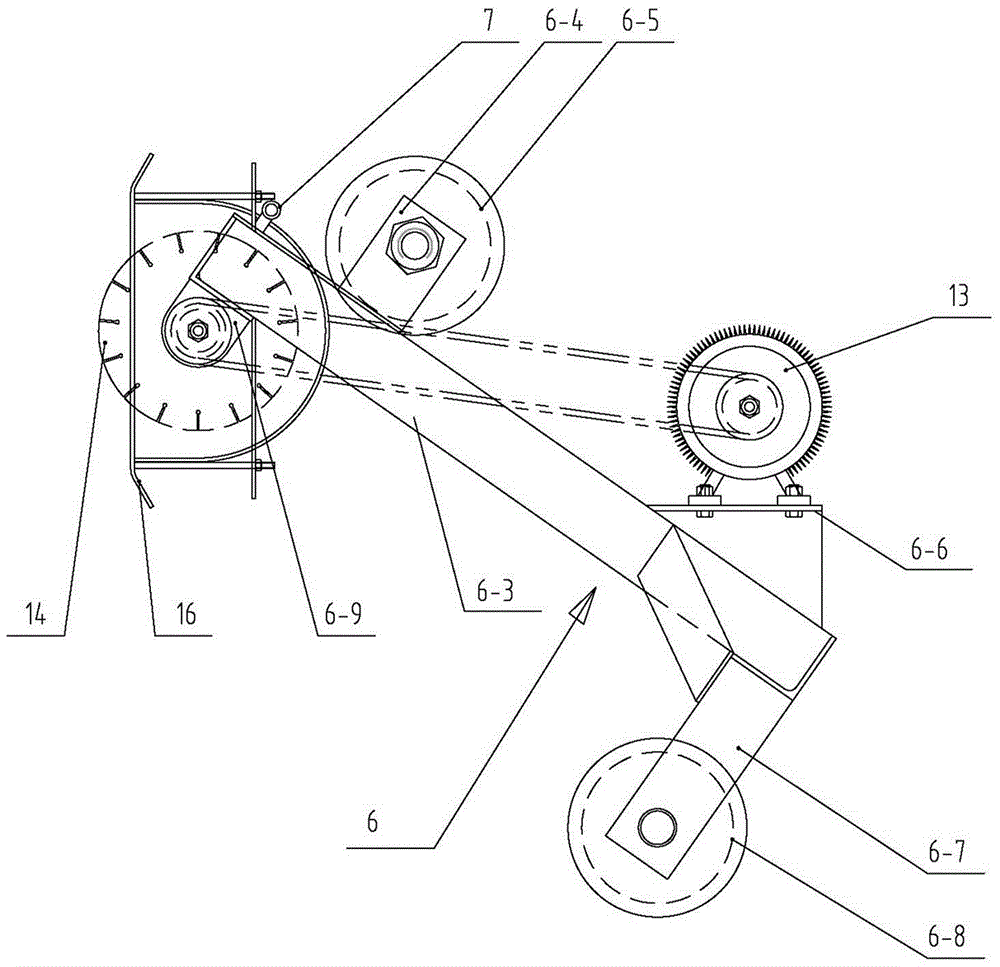

[0014] Such as figure 1 , image 3 As shown, the wall pipeline slotting machine of the present invention includes a mobile car body 1 with a handle 4, a slotting working part 2 driven by a motor 13 to drive a blade cutting mechanism 14 on the mobile car body 1, and a water spray dust removal device 3. Mobile car body 1 front part is provided with an I-beam climbing column 5, and I-beam climbing column 5 is provided with a crawling frame 6, and slotting work portion 2 is installed on the crawling frame 6. The top of the I-beam climbing column 5 is provided with a fixed pulley 8. The I-beam climbing column 5 is respectively hinged a support rod 9 at both sides of the fixed pulley 8 bottom, and the lower ends of the two support rods 9 are connected to the handlebar 4 both sides of the car body 1 rear portion respectively. An equipment and switch installation panel 10 is arranged between the handlebars 4 transversely. The equipment and switch installation panel 10 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com