electrolytic furnace

A technology of electrolytic furnace and hearth, which is applied in the direction of cells, etc., can solve the problems of decreased production capacity, hindrance to normal production, and decreased input power, and achieve the effects of large production capacity, uniform quality of metal products, and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

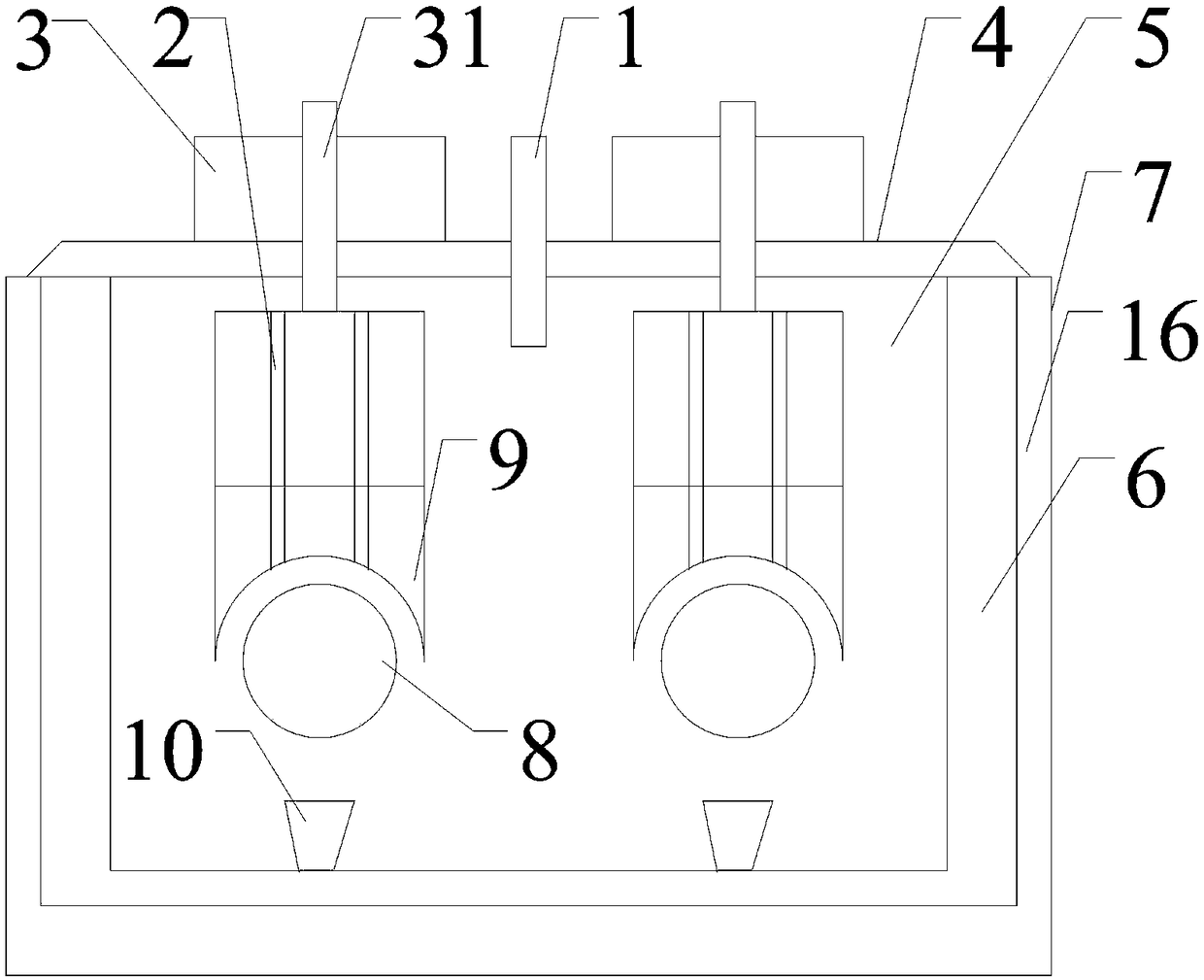

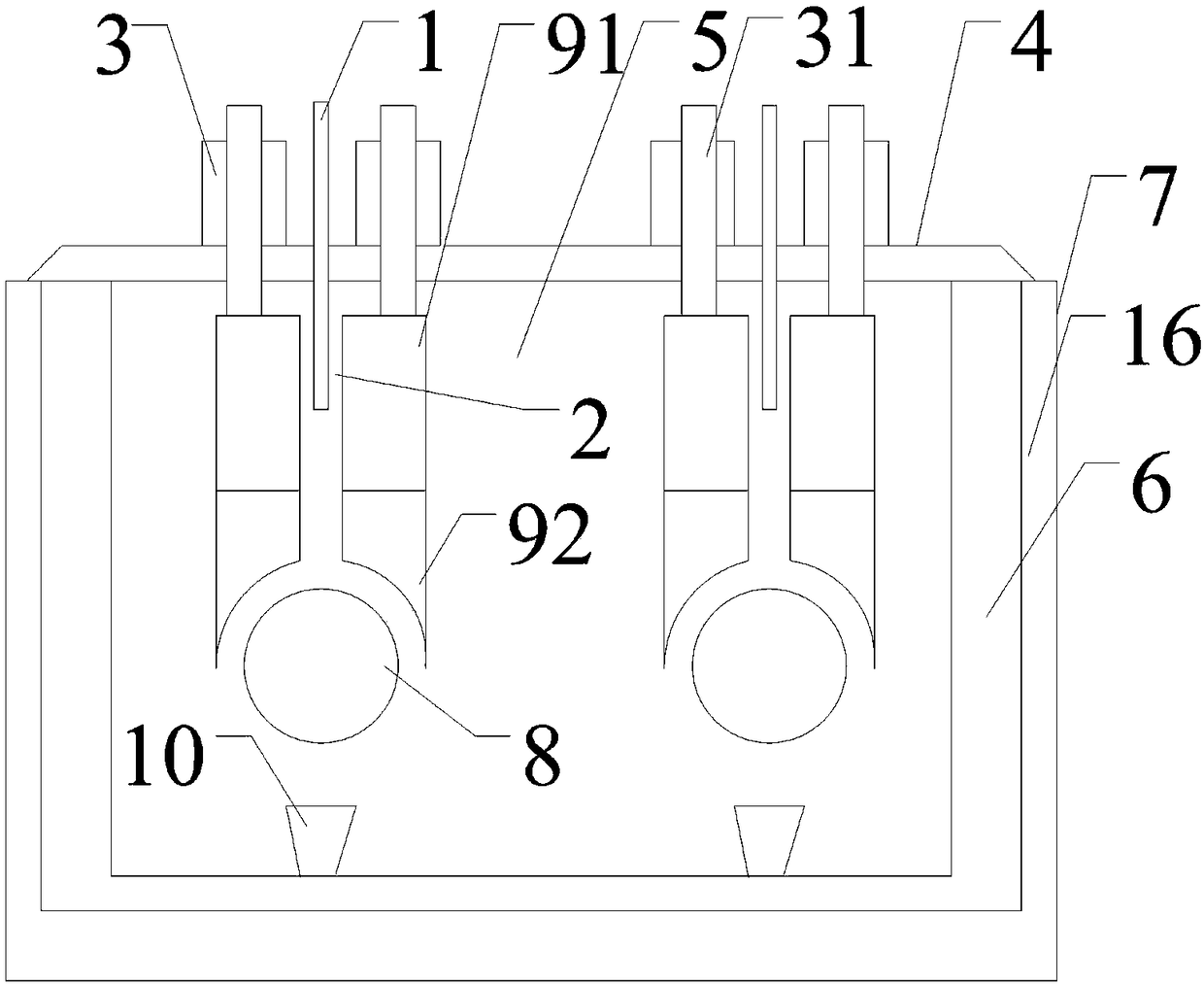

[0038] electrolytic furnace (see figure 1 , Figure 5 and Figure 9 ), including feed pipe 1, exhaust hole 2, anode adjustment part 3, furnace cover 4, furnace chamber 5, furnace wall 6, shell 7, cathode 8, anode 9, crucible 10, insulation layer 16, guide ring 19 and Waterproof insulation part 20. From the outside to the inside are the shell 7, the insulation layer 16, the furnace wall 6, and the furnace 5. The cavity in the furnace wall 6 forms the furnace 5 with an open top. From top to bottom are the anode adjustment part 3 , the furnace cover 4 , the furnace 5 , the anode 9 , the cathode 8 and the crucible 10 . The furnace cover 4 is covered above the opening of the furnace 5 . The number of the anode adjustment part 3, the anode 9, the cathode 8 and the crucible 10 is 1 each, and the cross section of the cathode 8 is circular, located in the furnace 5, and the two ends pass through the furnace wall 6, the insulation layer 16 and the shell respectively. 7 protrudes ou...

Embodiment 2

[0044] electrolytic furnace (see figure 1 , Figure 5 and Figure 9 ). This embodiment is basically the same as Embodiment 1, except that the number of the anode adjustment part 3, the anode 9, the cathode 8, the crucible 10, the guide ring 19 and the guide rod 31 is 2 pieces each, and the anode 9, the cathode 8 and the crucible 10 are arranged in parallel in the furnace 5 in pairs. Each of the cathodes 8 is inclined at 3° relative to the horizontal plane along the length direction. The two crucibles 10 are communicated and released from the furnace together. Each cathode 8 is inclined relative to the horizontal plane along the length direction so that the product leaves the electrolysis reaction area faster, which is beneficial to concentration and collection.

[0045] Compared with Embodiment 1, this embodiment improves the utilization rate of the furnace 5 and has a large production capacity, which is conducive to the enlargement of the electrolytic furnace. The quali...

Embodiment 3

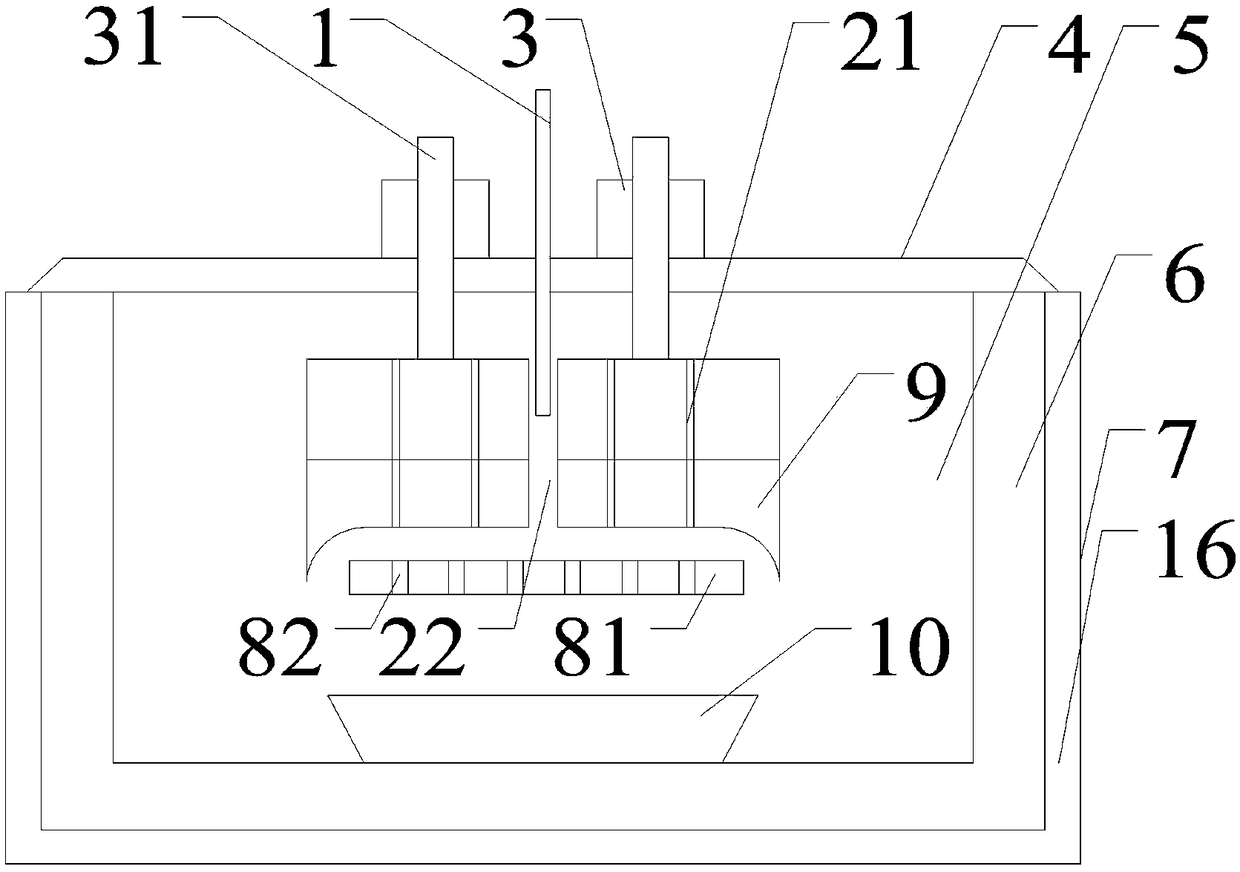

[0047] electrolytic furnace (see figure 2 , Figure 6 , Figure 7 , Figure 10 , Figure 11 and Figure 12 ), including feed pipe 1, exhaust channel 2, anode adjustment part 3, furnace cover 4, furnace chamber 5, furnace wall 6, shell 7, cathode 8, anode, crucible 10, insulation layer 16, guide ring 19 and anti Insulation part 20. From the outside to the inside are the shell 7, the insulation layer 16, the furnace wall 6, and the furnace 5. The cavity in the furnace wall 6 forms the furnace 5 with an open top. From top to bottom are the anode adjustment part 3, the furnace cover 4, the furnace 5, the anode, the cathode 8 and the crucible 10. The furnace cover 4 is covered above the opening of the furnace 5 . There are two anode adjustment components 3, and one anode, one cathode 8 and one crucible 10 each. Described cathode 8 is circular in cross section, is located in furnace 5, and one end passes through furnace wall 6, insulation layer 16 and casing 7 and stretches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com