High viscosity modified pi film

A high-viscosity and modified technology, applied in the field of PI film, can solve the problems of lowering the mechanical properties of materials and lowering the bottom, and achieve the effect of improving the surface viscosity, increasing the grafting rate and avoiding recession.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

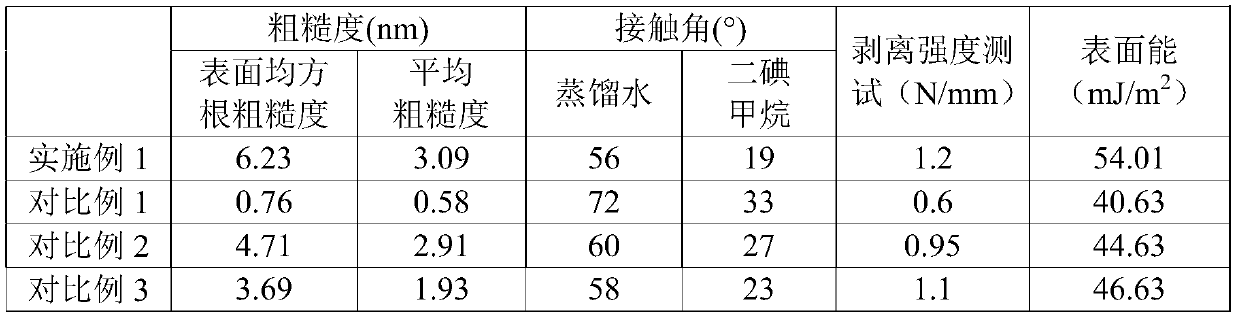

Examples

Embodiment 1

[0027] Preparation of surface modified PI film:

[0028] (1) Surface physical modification

[0029] A film with a PI film thickness of 10-20 μm is selected, and a convex-convex structure of 0.5-2 μm is formed on both sides of the PI film by compression molding of a molding die.

[0030] (2) Surface chemical modification

[0031] S1: Cleaning, take the physically modified PI film in a mixed weak alkaline solution of sodium carbonate, sodium phosphate and sodium dodecylbenzenesulfonate to degrease, decontaminate and microetch for 5-15 minutes, then wash it with tap water, dry for later use;

[0032] S2: Plasma treatment, place the cleaned and dried PI film in a plasma vacuum chamber, and use glow discharge to perform low-temperature plasma treatment on the PI film under an argon flow of 0.6 Torr, with a power of 35W and a treatment time of 1-2 60s;

[0033] S3: Activation, take out the treated PI film and put it in the air for 5 minutes to 1 hour to form active centers;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com