A method for synthesizing 2-triisopropylsilylethynylindole compounds

A technology based on triisopropylsilyl and acetylene indole, which is applied in the fields of chemical instruments and methods, compounds of group 4/14 elements of the periodic table, organic chemistry, etc., which can solve the problems of difficult availability of raw materials, restrictions on application and development, and reaction The conditions are not mild, etc., and the synthesis method is simple and easy to obtain, the reaction atom is economical, and the effect of broad application prospects is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

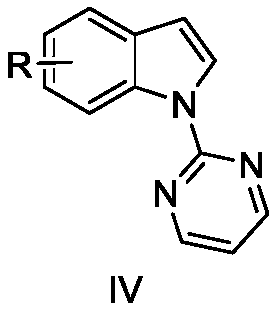

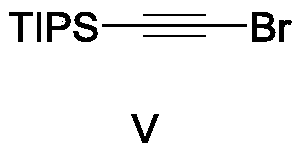

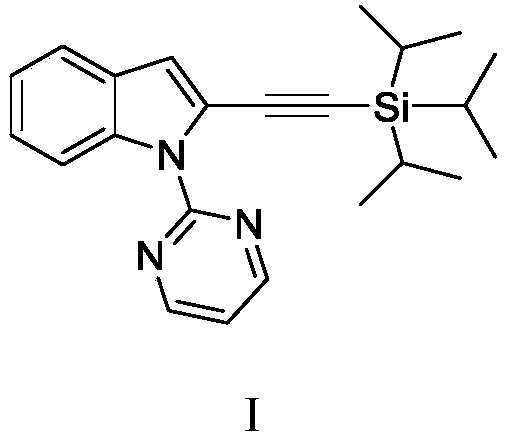

[0044] Synthesis of 1-(pyrimidinyl-2-yl)-2((triisopropylsilyl)ethynyl)-1H-indole

[0045] In the reaction vessel, add indole (6mmol, 702.9mg), NaH (mass fraction 60%, 10.8mmol, 432mg), DMF solvent, react under low temperature for 30 minutes; then add 2-chloropyrimidine (9.6mmol, 1099.5mg ), the mixture was reacted at 130°C for 24 hours, after 24 hours, the reaction was monitored by TLC, diluted with ethyl acetate, transferred to a 250mL separatory funnel, washed three times with water, and after washing DMF, the organic phase was collected and washed with anhydrous sodium sulfate After removing water, the organic solvent was removed by rotary evaporation under reduced pressure to obtain a crude product, and the compound 1-(pyrimidinyl-2-yl)-1H-indole reactant was obtained by column chromatography (ethyl acetate:petroleum ether=1:99) . Accurately weigh the 1-(pyrimidinyl-2-yl)-1H-indole reactant (0.2mmol, 39.2mg) with an electronic balance of one ten-thousandth, transfer it to...

experiment example 2

[0048] Synthesis of 4-methyl-1-(pyrimidin-2-yl)-2-((triisopropylsilyl)ethynyl)-1H-indole

[0049] Take a 100mL round bottom flask and a suitable size magnet, weigh 4-methylindole (5mmol, 656mg) and dissolve it in N,N-dimethylformamide (DMF), put it in an ice-water bath and slowly add NaH (Mass fraction 60%, 7.5mmol, 300mg) for hydrogen extraction reaction, reacted at low temperature for 1 hour, then added 2-chloropyrimidine (7.5mmol, 855mg), the mixture was reacted at 130°C for 24 hours, and passed through TLC monitored the completion of the reaction, diluted with ethyl acetate, transferred to a 250mL separatory funnel, washed three times with water, and washed DMF, collected the organic phase to remove water with anhydrous sodium sulfate, and removed the organic solvent by rotary evaporation under reduced pressure to obtain the crude product , The product 4-methyl-1H-(pyrimidin-2-yl)-1H-indole reactant was obtained by column chromatography (ethyl acetate:petroleum ether=3:95)...

experiment example 3

[0052] Synthesis of 5-methyl-1-(pyrimidin-2-yl)-2-((triisopropylsilyl)ethynyl)-1H-indole

[0053] Take a 100mL round bottom flask and a suitable size magnet, weigh 5-methyl-1H-indole (5mmol, 755mg) and dissolve it in N,N-dimethylformamide (DMF), and place it in an ice-water bath Slowly add NaH (mass fraction 60%, 7.5mmol, 300mg) for hydrogen extraction reaction, react at low temperature for 1 hour, then add 2-chloropyrimidine (7.5mmol, 855mg), and react the mixture at 130°C for 24 hours, After 24 hours, the reaction was monitored by TLC, diluted with ethyl acetate, transferred to a 250mL separatory funnel, washed three times with water, and after washing DMF, the organic phase was collected to remove water with anhydrous sodium sulfate, and the organic solvent was removed by rotary evaporation under reduced pressure. The crude product was obtained, and the product 5-methyl-1H-(pyrimidin-2-yl)-1H-indole reactant was obtained by column chromatography (ethyl acetate:petroleum eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com