Preparation of a nano-superstructure of antimony phosphate and its new application in photocatalysis

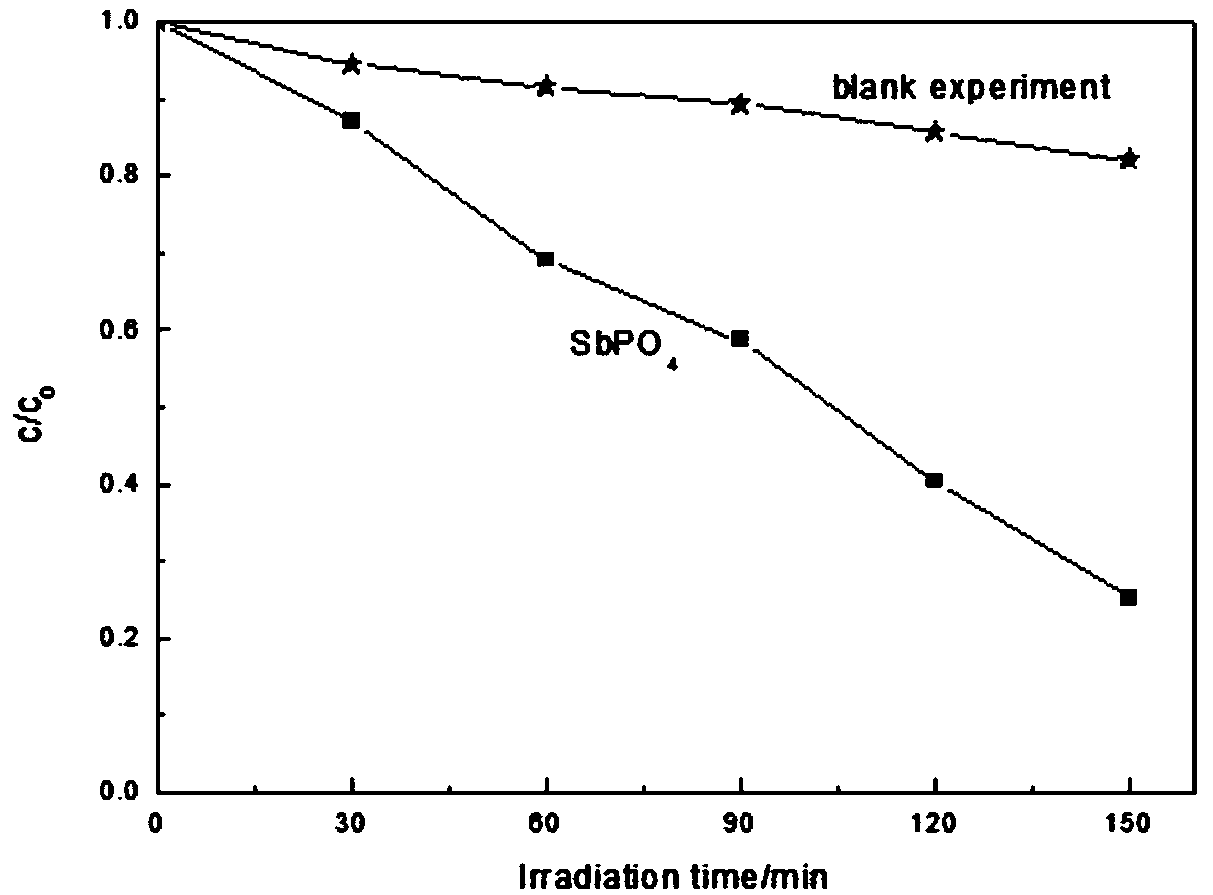

An antimony phosphate nanometer and superstructure technology is applied in the field of photocatalytic materials, which can solve the problems of no application report of antimony phosphate, cumbersome operation, and difficulty in obtaining raw materials, and achieves the effects of simple preparation method, good photocatalytic activity, and wide variety of types.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

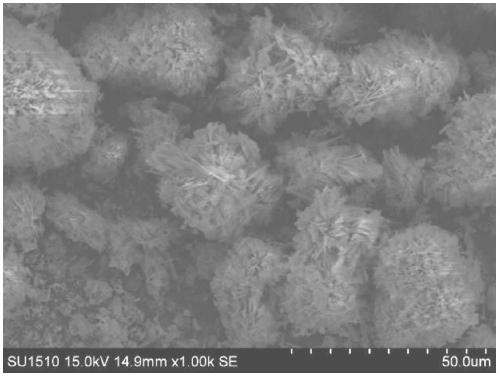

[0024] Add 65mL of water to the beaker, add 1.967g of diethylenetriaminepentaacetic acid and 1.141g of antimony trichloride in turn, and stir thoroughly in a water bath at 60°C for 1h; then add 0.575g of ammonium dihydrogen phosphate, and stir thoroughly for 0.5h to form a precursor The precursor mixed solution is filtered to obtain the precursor solution and the precursor precipitate. Put the precursor solution in a 60°C water bath for 10 to 20 minutes to form a suspension system; take the suspension clarified liquid and all the precursor precipitation in the suspension system and pour it into a 50mL polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle. The volume of the suspension clarified liquid is half of the suspension system, subjected to constant temperature hydrothermal reaction at 160° C. for 10 h, centrifuged, washed and dried to obtain the product.

[0025] Electron microscope observation and X-ray diffraction determination were carried out on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com