Phosphor block belt conveyor capable of performing curved running and curved operation

A belt conveyor, bending technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as restricting the efficiency of combined coal mining units, and achieve the effects of increased life, flexible walking and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0055] 1. Bending running and running Lin block belt conveyor

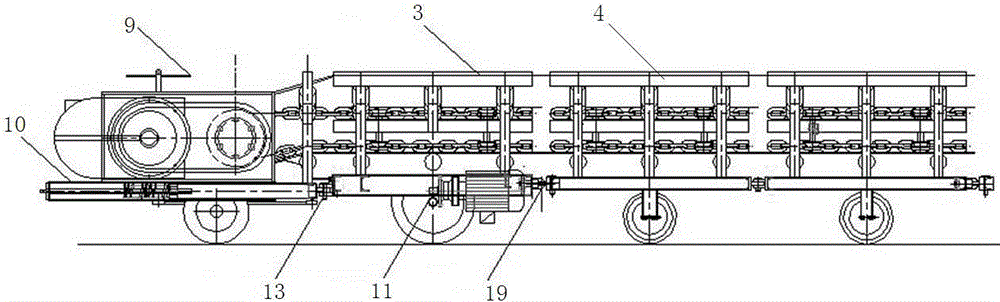

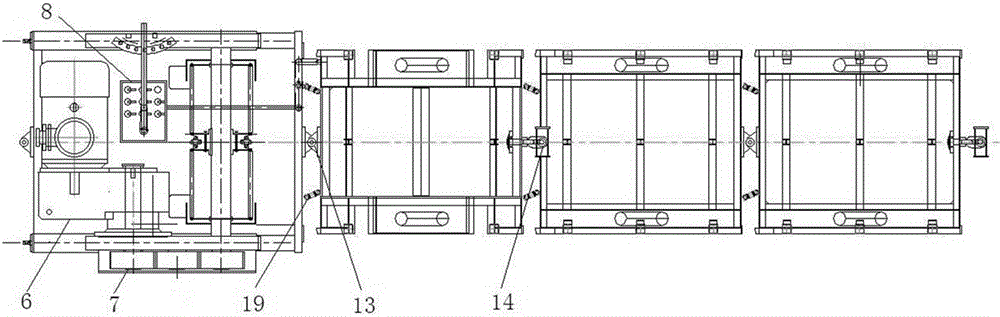

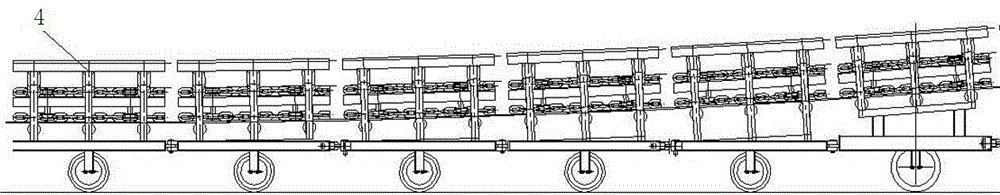

[0056] 1. Structural composition: such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the belt conveyor that can bend and run is composed of a driving cannon, an ordinary cannon, a circular chain, a needle sprocket roller, a roller driving device, a tape scale, an upper grooved idler group, and a lower parallel support. It is composed of roller group, tensioning device, gun carriage driving device, steering mechanism, hinged seat, needle roller sprocket roller cover, adjustable chute, material guide trough, electrical control, etc. The driven cannon and the ordinary cannon are articulated alternately through two kinds of hinges to form a dynamic drag combination. The needle sprocket roller is installed on the head and tail drive cannon of the bendable running and bending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com