Device and method for controlling the gap between base and resin tank of dlp light-curing 3D printer

A 3D printer and resin tank technology, applied in the field of 3D printing, can solve the problems of damage to the resin tank, large gap between the base and the resin tank, inconsistent thickness of tempered glass, etc., and achieve the effect of high reliability and simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

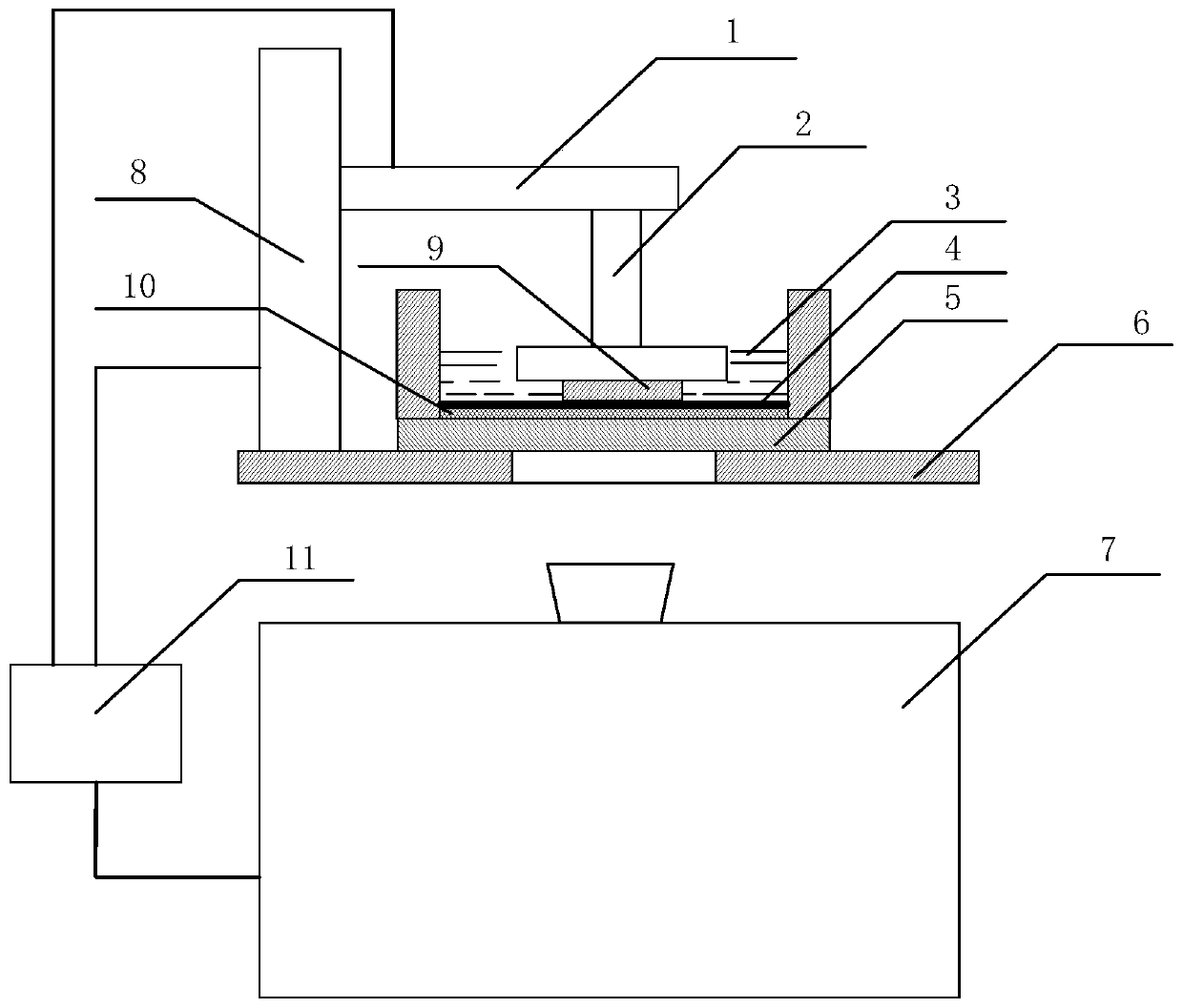

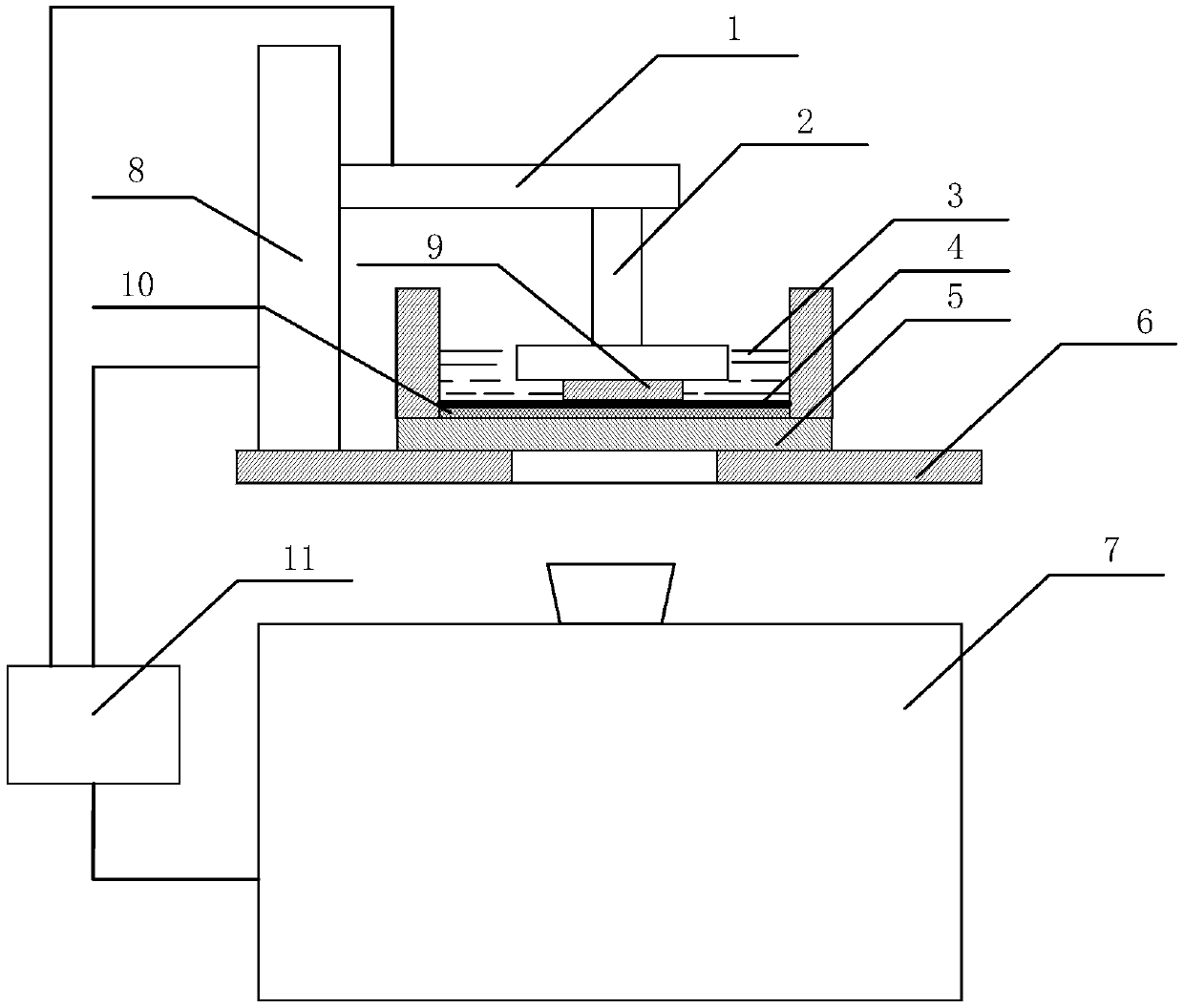

[0035] Such as figure 1 As shown, the device for controlling the gap between the DLP light-curing 3D printer base and the resin tank includes: a DLP projector 7 installed under the workbench 6, and the DLP projector 7 projects upward; a resin tank is fixed above the workbench 6, Photosensitive resin 3 is housed in the resin tank, and the inner bottom surface of the resin tank is made of toughened glass 5, and the silica gel coating 10 is evenly coated on the toughened glass 5 upper surface, and the film (using Teflon film 4 in this embodiment) is pasted on On the surface of the silicone coating 10, the projection light of the DLP projector 7 shines on the surface of the photosensitive resin 3 through the resin tank; the tempered glass 5 is a high-strength, transparent glass; the silicone coating 10 is a transparent, elastic Chemical materials are evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com