Intelligent control method in robot spot welding

A technology of intelligent control and robotics, which is applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of failure to detect spot welding quality, low equipment utilization, and heavy workload, so as to improve enterprise efficiency and Competitiveness, reducing labor waste, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below according to the accompanying drawings.

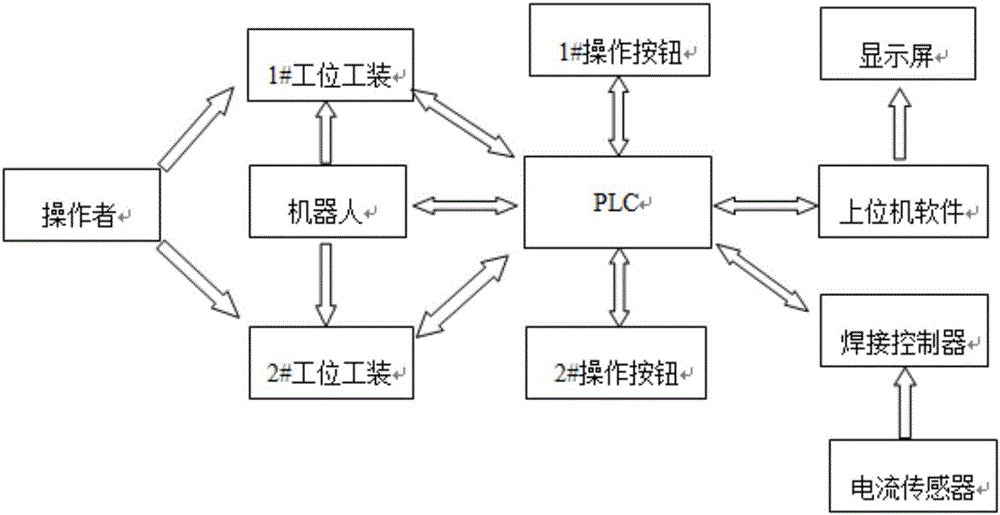

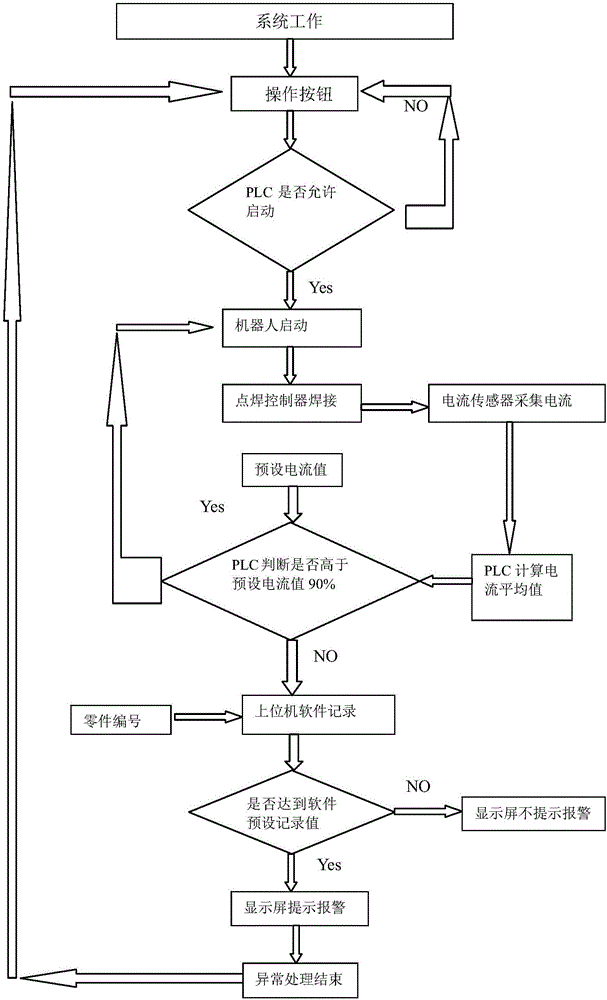

[0035] Such as figure 1 As shown, the robot is bidirectionally connected to the PLC, and the PLC is bidirectionally connected to the upper computer and the welding controller; the output end of the upper computer is connected to the display screen; the input end of the welding controller is connected to the output end of the current sensor; There are 2 workstations of the robot, and the operation buttons of the robot are provided on the workstations; the PLC is provided with a manual load rate module and a spot welding quality monitoring module.

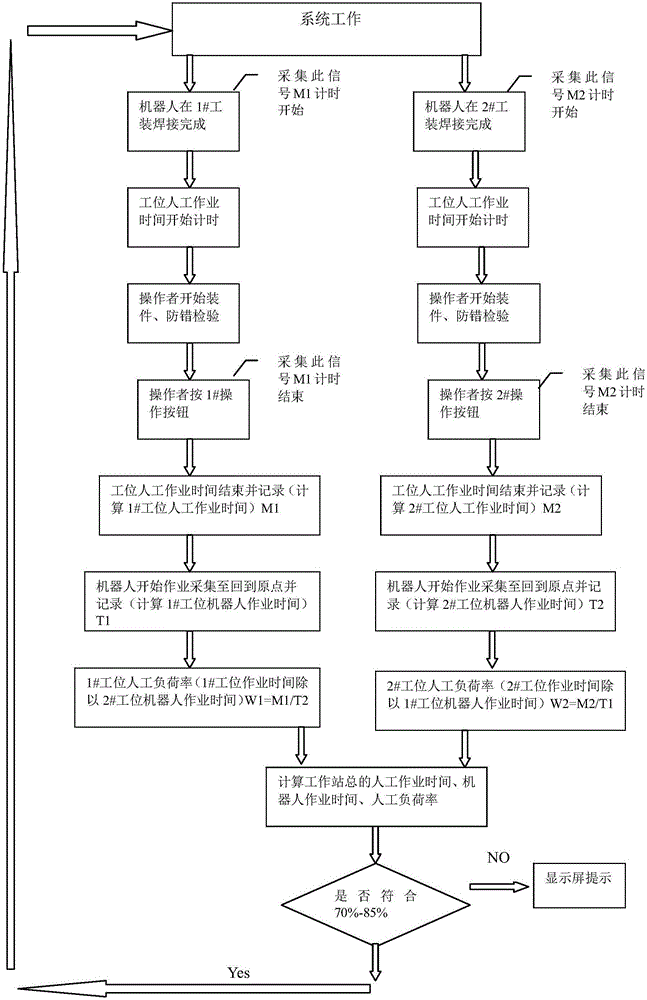

[0036] Such as figure 2 As shown, the workflow of the artificial load rate module is as follows:

[0037] (1) The system starts to work;

[0038] (2) The welding work of station tooling 1 and station tooling 2 of the robot is completed;

[0039] (3) The manual operation time of station tooling 1 and station tooling 2 starts cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com