Miniature flexible ring piece test press

A miniature and ring technology, applied in metal rolling and other directions, can solve the problems of bloated mechanism, low efficiency and inflexibility, and achieve the effect of reducing the tonnage and power of the equipment, shortening the distance of action execution, and reducing the size of the space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

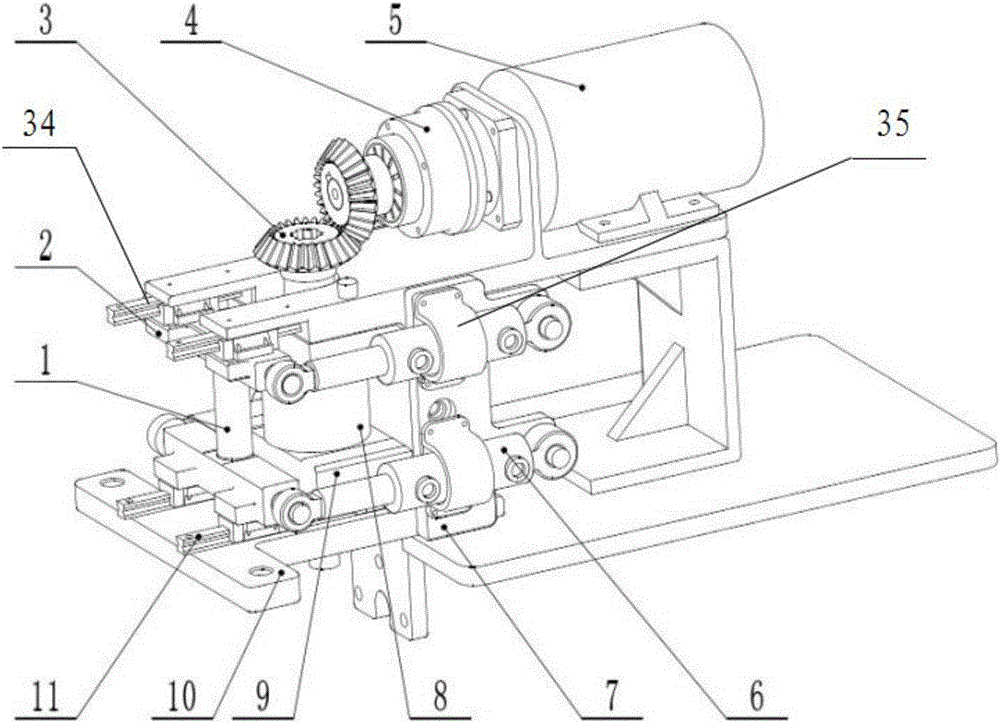

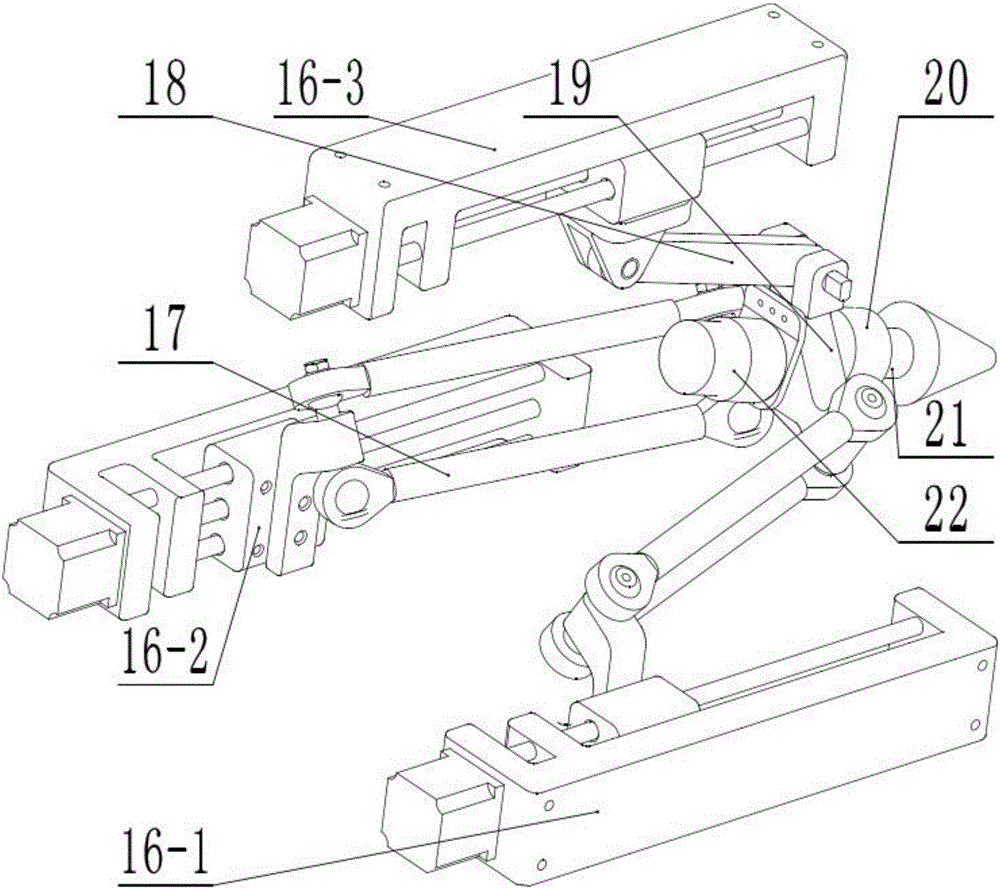

[0018] exist Figure 1 to Figure 5 In the shown schematic diagram of the present invention, the fixed base A27 is provided with a main roll frame 10 and a motor support frame 33, the main roll frame is a C-shaped frame, and the bottom of the main roll frame is connected with the fixed base A27. The bottom of the main roll frame is provided with a roll holding hydraulic cylinder 12, and the top of the main roll frame is equipped with a motor 5 and a planetary reducer 4, and the motor and the planetary reducer are separated by a partition with a through hole on the main roll frame. The main roller frame is provided with a main roller chock 9 and a group of parallel main roller slide rails 11, and the main roller chock is placed on the two main roller slideways, which is convenient for changing rolls. The motor support frame is a channel steel type with side opening, the bottom is connected with the fixed base A, and the top is connected with the main roller frame. The upper cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com