A kind of hollow blade viscoelastic plastic soft mold internal pressure forming method and forming device

A hollow vane and viscoelastic technology, which is applied in the field of hollow parts forming, can solve the problems of poor wall thickness uniformity, low dimensional accuracy, and complicated process, and achieve high forming dimensional accuracy, good wall thickness uniformity, and simple forming process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this implementation mode, this implementation mode is realized through the following steps:

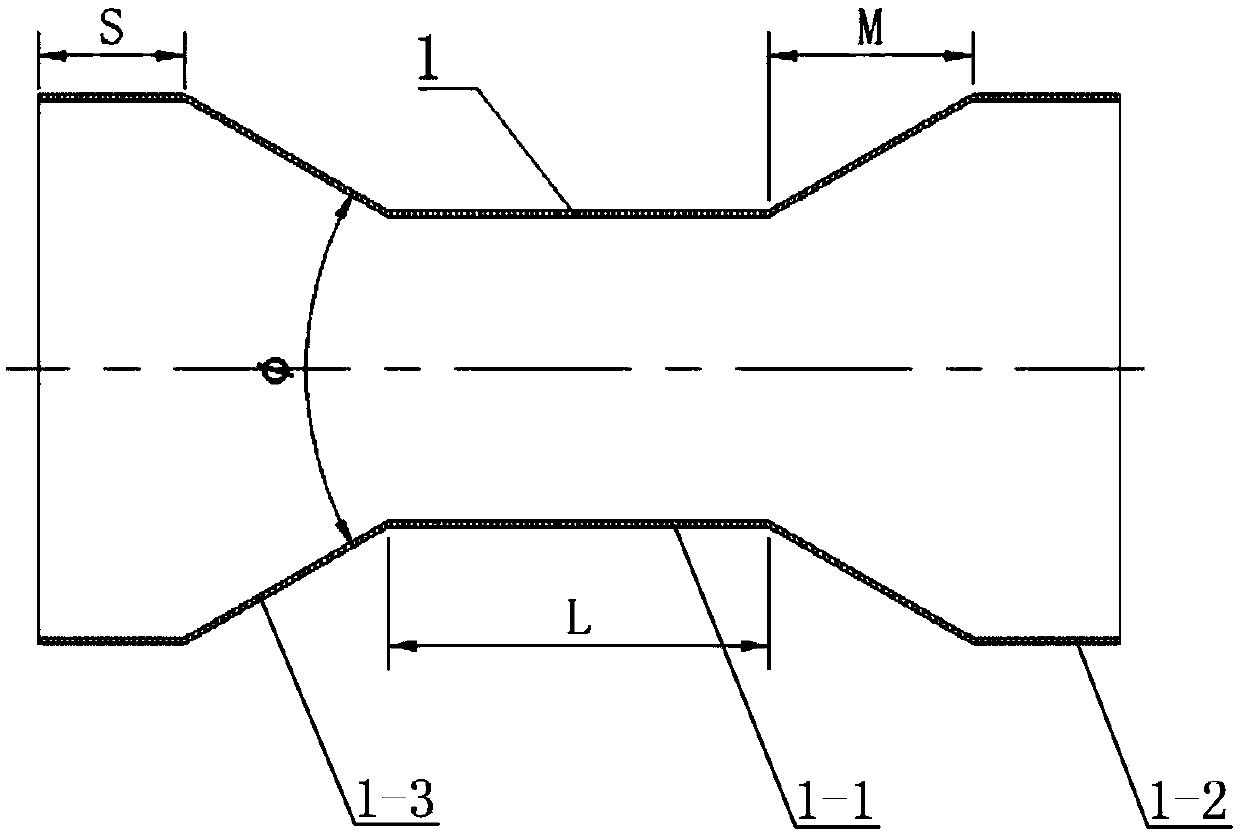

[0022] Step 1. Blank making 1: Rolling and welding the sheet metal to form a circular shell, and processing the fixed sections 1-2 at both ends of the circular shell into a diameter larger than that of the middle airfoil section 1-1, and the airfoil section 1-2 1 and the fixed section 1-2 is the transition section 1-3, see figure 1 ;

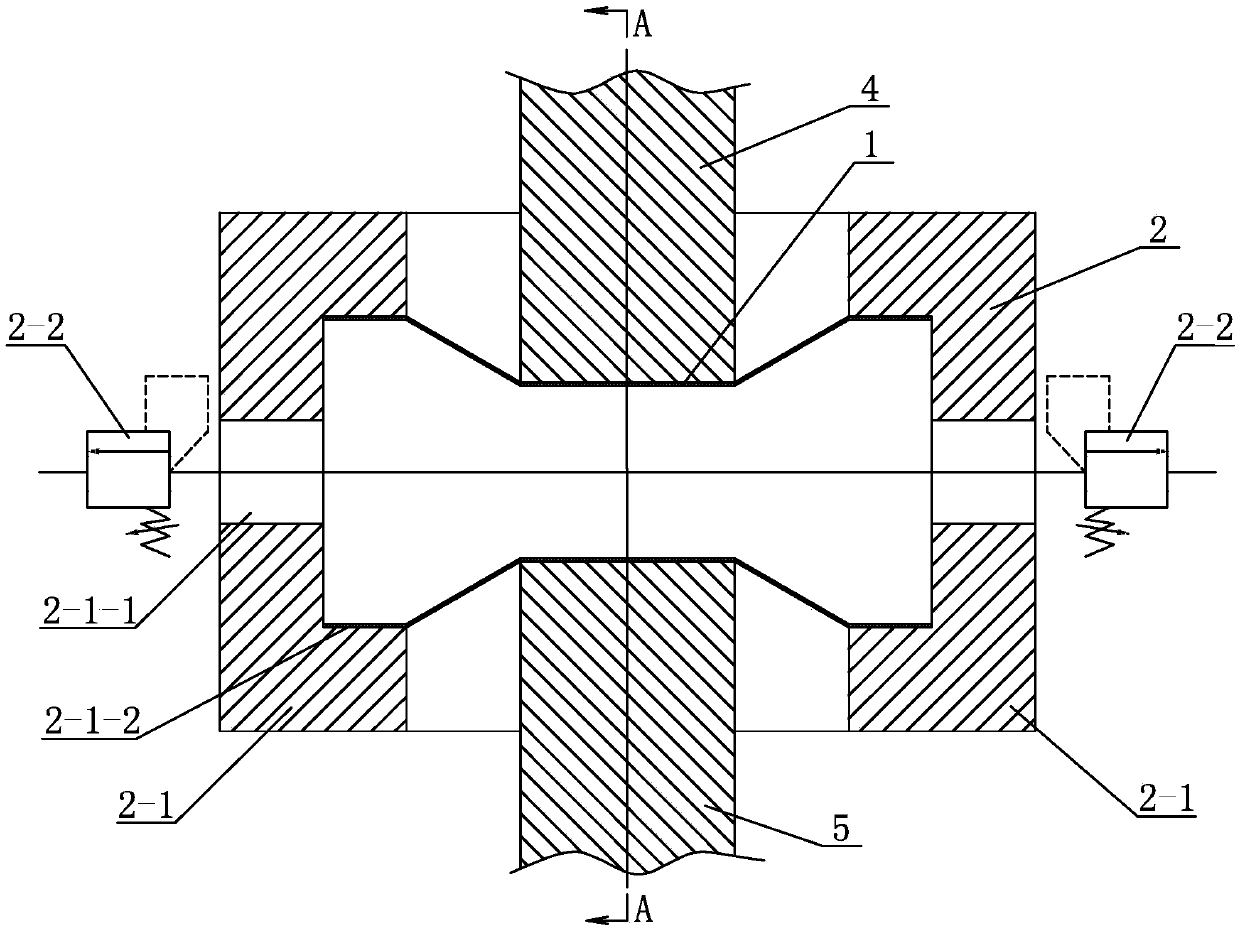

[0023] Step 2: Install the tube blank 1 into the sealing device 2: put the tube blank 1 into the sealing device 2, and clamp and fix the tube blank 1;

[0024] Step 3: Install the sealing device 2 into the press: install the sealing device 2 with the tube blank 1 on the press, align with the upper mold 4 and the lower mold 5, and position;

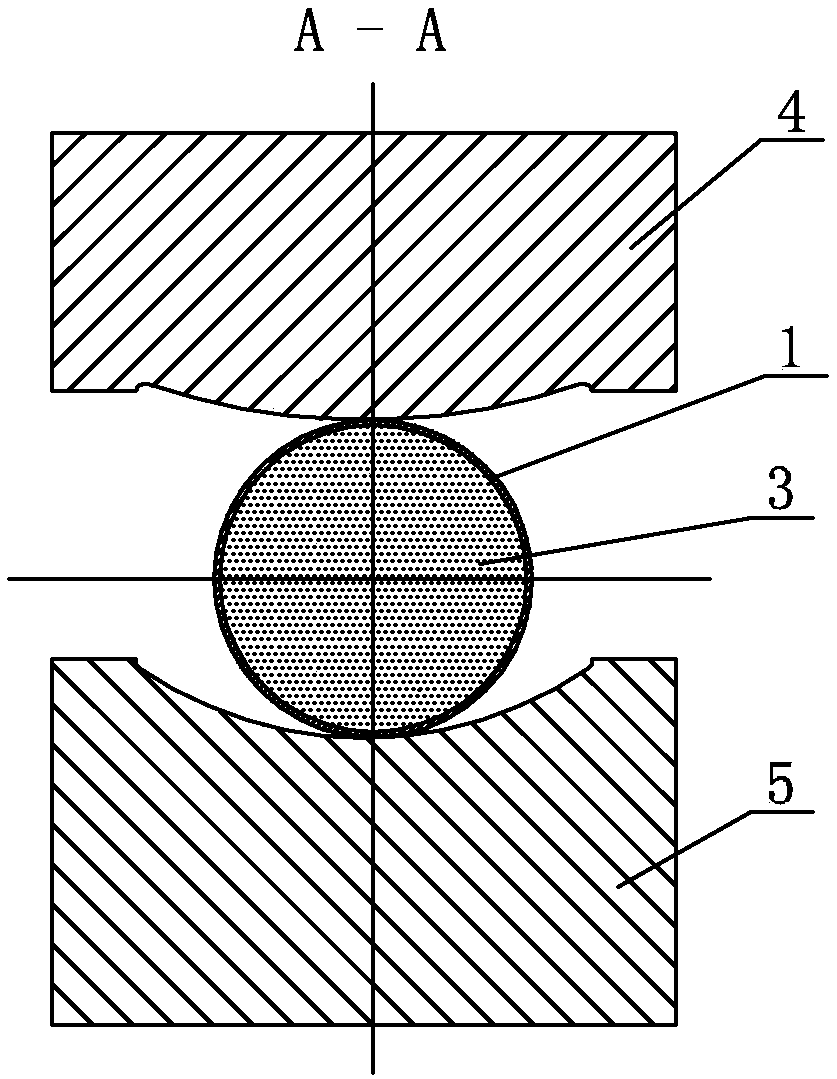

[0025] Step 4: Inject viscoelastic plastic material 3: inject viscoelastic plastic material 3 into the shell 1, and at the same time...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 1 This embodiment will be described. In this embodiment, the wall thickness of the shell blank 1 in step 1 is 0.15 mm to 1 mm. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 To describe this embodiment, in this embodiment, the material of the shell blank 1 in step 1 is stainless steel, titanium alloy or superalloy. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com