A jujube conveying and turning device

A turning device and jujube technology, applied in sorting and other directions, can solve the problems of increasing production costs, single jujube bearing roller, unfavorable jujube detection and classification, etc., and achieve the effect of reducing friction, reducing mechanical damage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

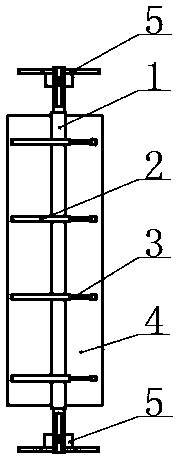

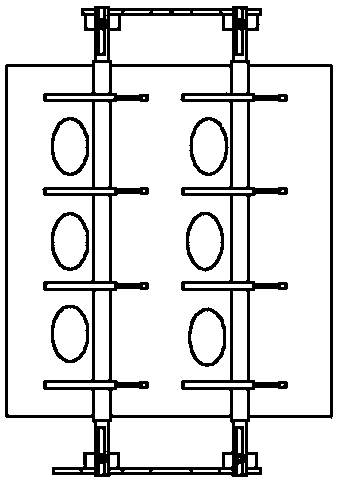

[0023] refer to Figure 1 to Figure 4 , this example is the structure and working process of a kind of jujube conveying turning device.

[0024] The jujube conveying turning device is mainly composed of a bearing shaft (1), a jujube limit baffle (2), a fastening screw (3), a friction belt (4), a conveying chain (5) and the like.

[0025] In the overall structure of the jujube conveying and turning device, the bearing shaft (1) can be connected with the conveying chain (5) through the pin holes (6) at both ends, and at the same time provide support for the jujube limit baffle (2).

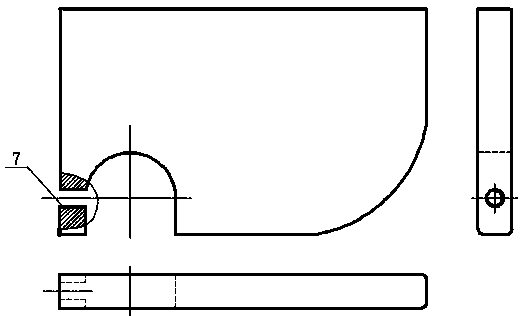

[0026] The jujube limit baffle (2) is designed with a smooth arc shape on the side close to the friction belt (4) at the bottom to reduce friction with the friction belt (4), and the jujube limit baffle (2) is close to the friction There is a U-shaped groove on one side of the belt (4) to cooperate with the bearing shaft (1), and the end of the U-shaped groove opposite to the forward direction of t...

example 2

[0030] Compared with Example 1, the difference of this example is that the running speed of the bearing shaft (1) and the friction belt (4) of the above-mentioned red date conveying and turning device is different, and the red dates are realized by using the principle of differential speed and friction rolling. Autobiography in Transit.

example 3

[0032] Compared with Example 2, the difference of this example is that the installation position of the jujube limiting baffle (2) on the bearing shaft (1) can be adjusted according to the size of the jujube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com