a masking tool

A technology of tooling and shielding parts, which is applied in the field of shielding tooling, can solve the problems that the workpieces of the shielding parts are not universal and cannot be reused, and achieve the effects of high degree of generalization, simple and reliable structure, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

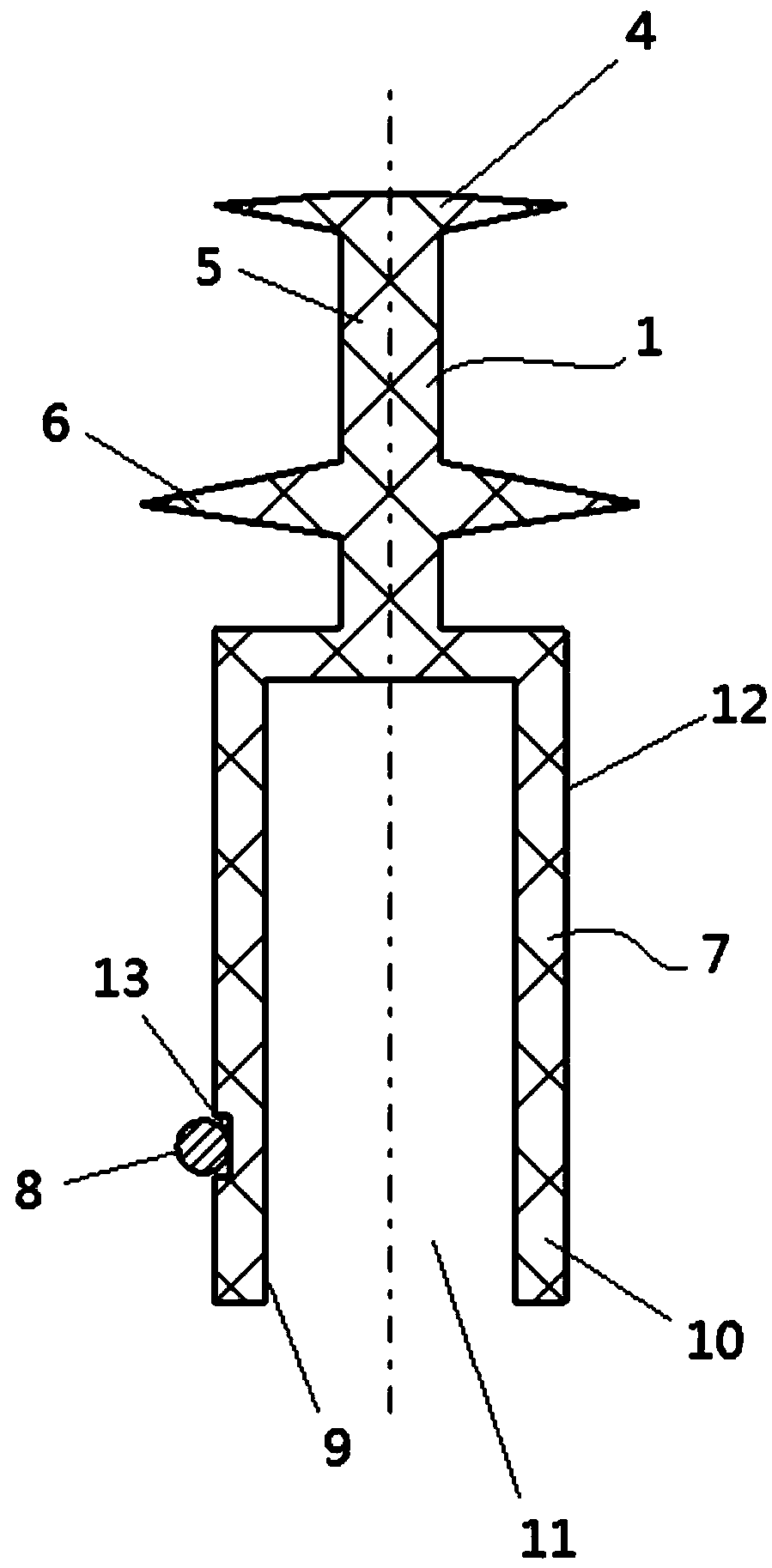

[0034] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

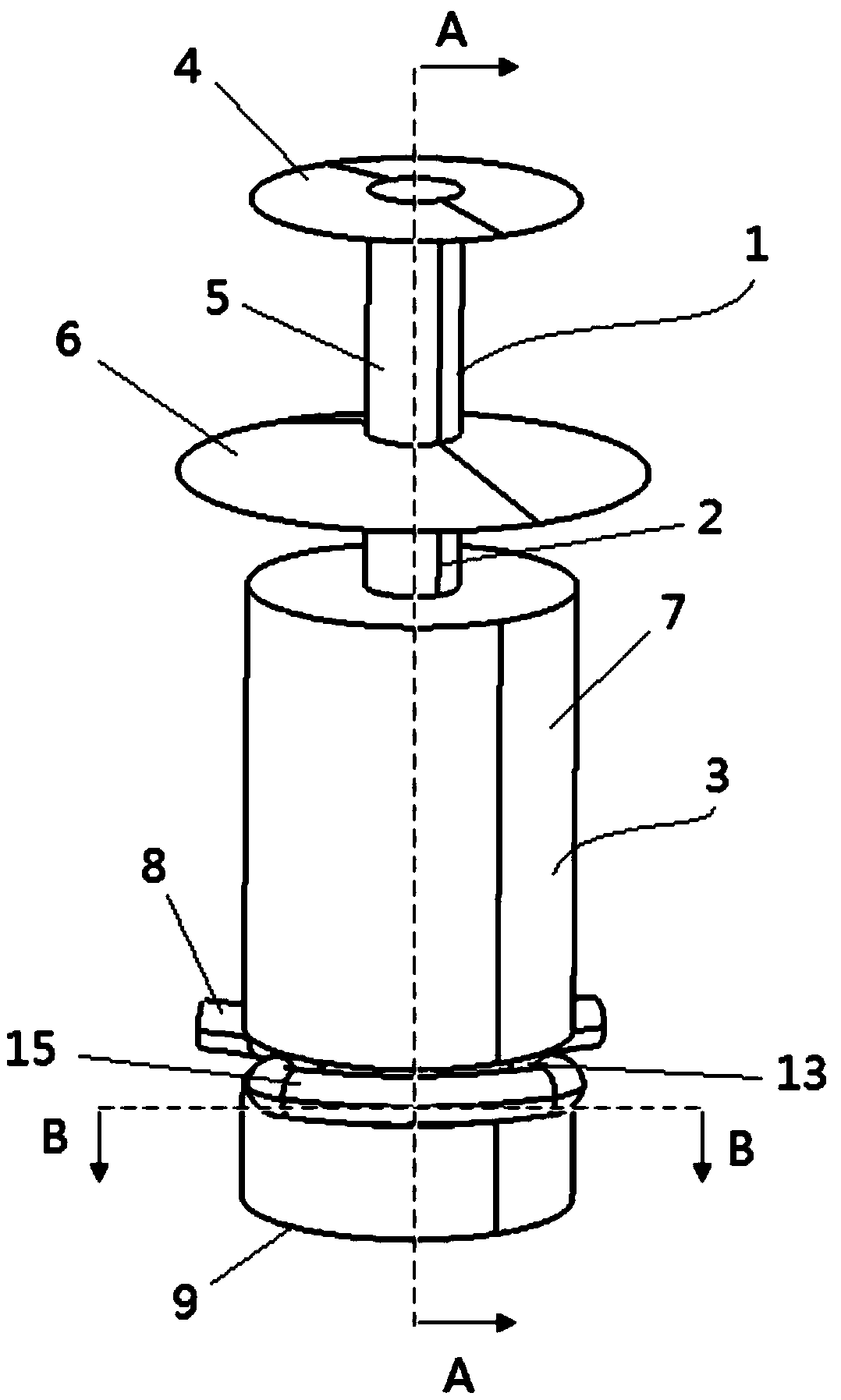

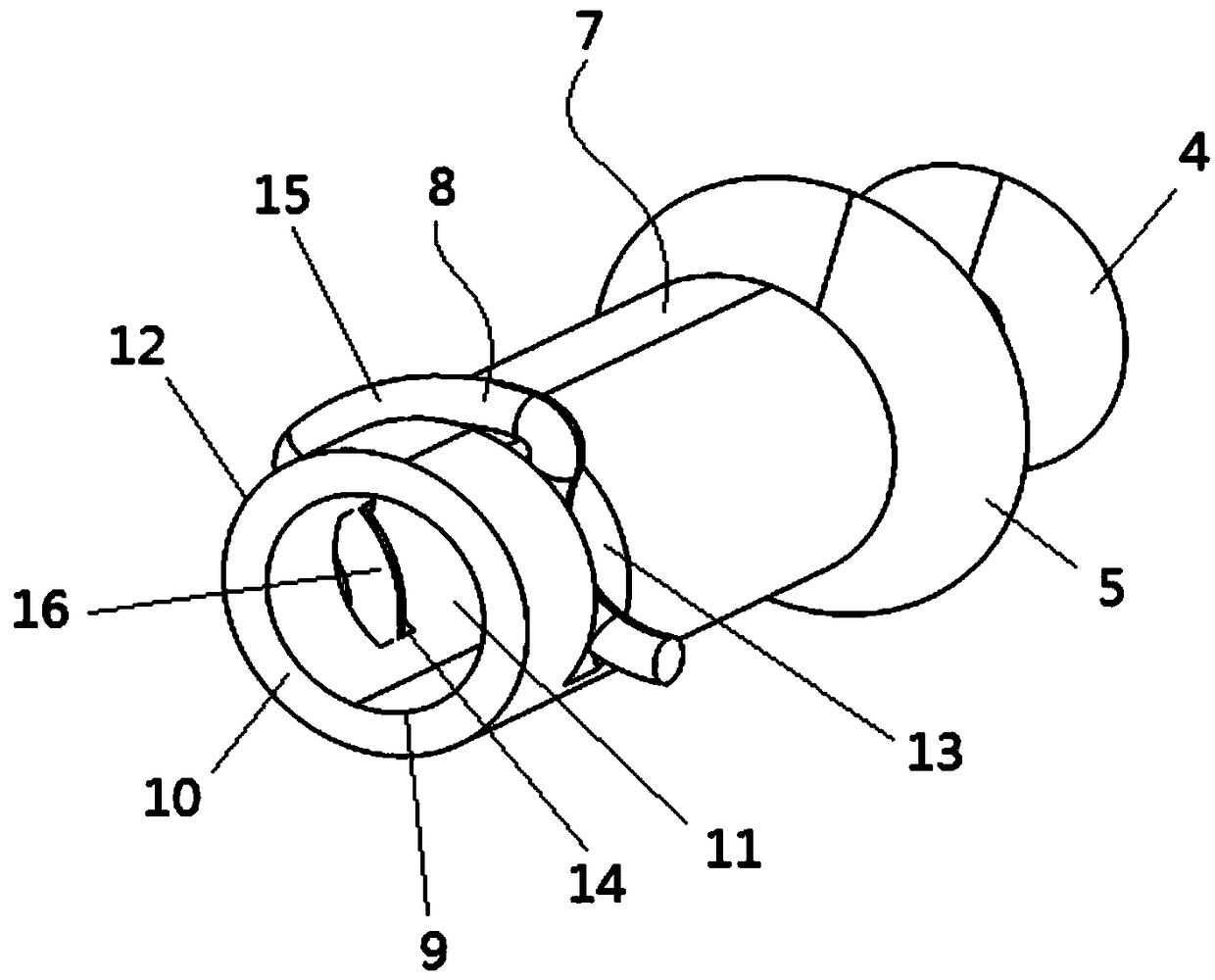

[0035] Aiming at the problem in the prior art that the workpieces used for shielding parts during body painting are not universal or reusable, the present invention provides a shielding tool, such as Figure 1 to Figure 6 shown, including:

[0036] The first shielding part 1, the connecting part 2 and the second shielding part 3;

[0037] Wherein, the first shielding part 1 includes a first positioning end 4 and a second positioning end 6 connected to the first positioning end 4 through a connecting section 5, and the edge material of the first positioning end 4 is elastic material, the cross-sectional dimensions of the first positioning end 4 and the second positioning end 6 are greater than the cross-sectional dimension of the preset nut through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com