Vacuum pipeline device of oil filter

A technology for vacuum pipelines and oil purifiers, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of high cost of vacuum pipelines, difficult to clean, difficult to operate, etc., and achieve long service life and strong corrosion resistance. , the effect of large flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

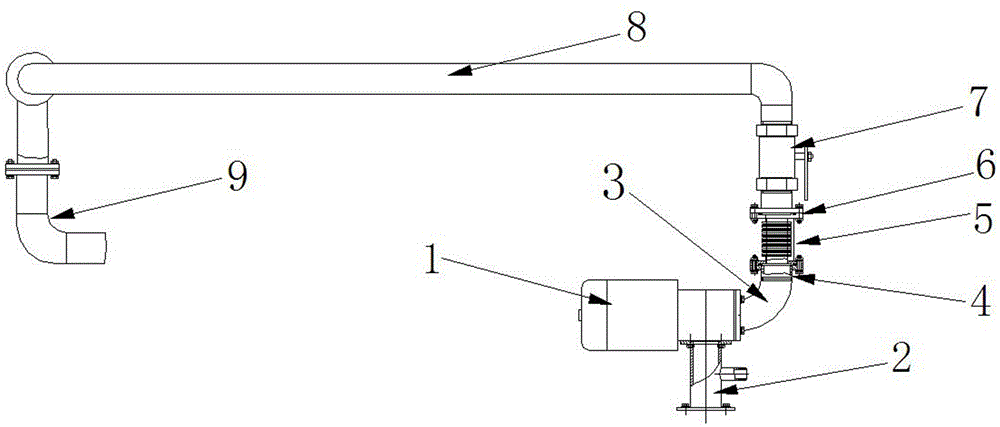

[0015] A vacuum pipeline device for an oil filter, which is composed of a solenoid valve 1, a solenoid valve seat pipe 2, an elbow 3, a bellows lower connection plate 4, a bellows 5, a bellows upper connection plate 6, a valve 7, a straight pipe 8, The pipe connection plate 9, the upper connection plate 10, the vertical cylinder 11, the lower connection plate 12, and the pipe joint 13 are characterized in that the solenoid valve 1 is located at the upper end of the solenoid valve seat pipe 2 and is connected with the elbow 3, and the bellows 5 are respectively connected with the The lower connection plate 4 of the bellows and the upper connection plate 6 of the bellows are connected, the lower connection plate 4 of the bellows is connected with the elbow 3, the upper connection plate 6 of the bellows is connected with the valve 7, the straight pipe 8 is connected to the upper end of the valve 7, and the straight pipe 8 is connected to the pipe connection plate 9 connected.

Embodiment 2

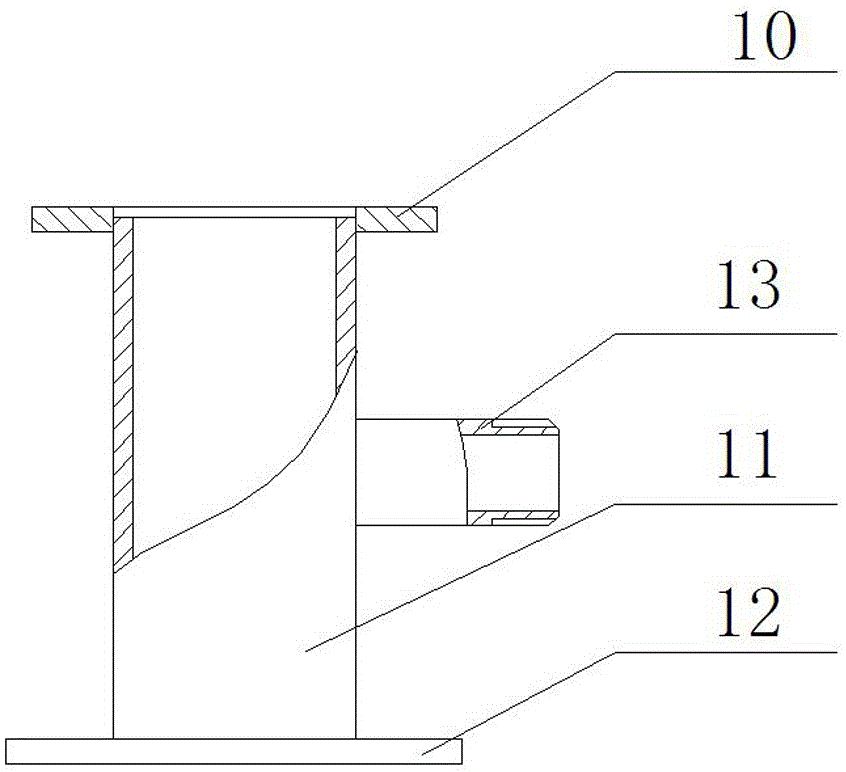

[0017] Electromagnetic valve seat pipe is made of upper connection plate 10, vertical tube 11, lower connection plate 12, pipe joint 13.

Embodiment 3

[0019] The elbow 3 is a steel elbow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com