Static pressure unloading guide rail convenient for tightness adjustment

A kind of elastic and static pressure technology, applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., can solve the problems of reducing wear resistance stability, the tightness of slider movement should not be adjusted, etc., to improve wear resistance, improve Load conditions, the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Such as figure 1 , figure 2 As mentioned above, in this embodiment, a static pressure unloading guide rail that is easy to adjust tightness includes a main guide rail 1, an auxiliary guide rail 2 installed on the main guide rail 1 and used for bearing force, and cooperatingly installed on the main guide rail 1 and the auxiliary guide rail 2 The slider 3 on the slider 3 is provided with a through hole 4 at the corresponding position, and the through hole 4 is equipped with a pressing part, and also includes an adjustment part 10 installed on the end face of the pressing part and used to adjust the tightness of the pressing part. .

[0020] In actual working conditions, due to the load-bearing effect of the auxiliary guide rail 2 and the pressing part, it can share part of the load on the main guide rail 1, so as to improve the load condition of the main guide rail 1, improve its wear resistance and stability of low-speed motion , and an adjusting part 10 is set on the...

Embodiment 2

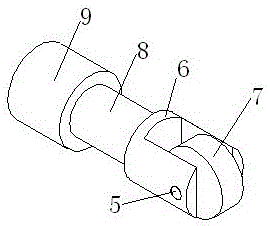

[0022] This embodiment further limits the above-mentioned embodiments. In this embodiment, if image 3 As shown, the above-mentioned pressing part includes an adjusting screw 9, an elastic body 8 installed on the adjusting screw 9, a piston pin 6 installed on the free end of the elastic body 8, a rotating shaft 5 installed on the piston pin 6, and a joint through the rotating shaft 5 The rolling body 7 installed on the piston pin 6 , the adjusting part 10 is installed on the end face of the adjusting screw 9 .

[0023] The user can realize the adjustment of the movement tightness of the slider 3 by adjusting the adjustment part 10 , which is simple and convenient to operate and highly practical.

[0024] When in use, since the elastic body 8 itself has an elastic force in the axial direction, under the joint action of the adjustment screw 9, the piston pin 6 and the rolling body 7, there is a pressing force in the elastic body 8. In a certain state, due to When the relative p...

Embodiment 3

[0026] This embodiment is further limited on the basis of the above-mentioned embodiments. In this embodiment, the above-mentioned rolling member 7 is a rolling bearing, the adjusting part 10 is an adjusting nut, and the elastic body 8 is a spring. Since the rolling bearing, the adjusting nut, and the spring all belong to Common items, and its price is cheap, so adopting the above structure can save manufacturing cost while achieving the purpose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com