Production equipment and method for manufacturing products in the form of plates or blocks

A technology of production equipment and production methods, applied in the direction of manufacturing tools, layered products, clay preparation devices, etc., can solve the problems of unfavorable new process expansion, too many restrictions, and inability to improve other processes, so as to add new types , The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

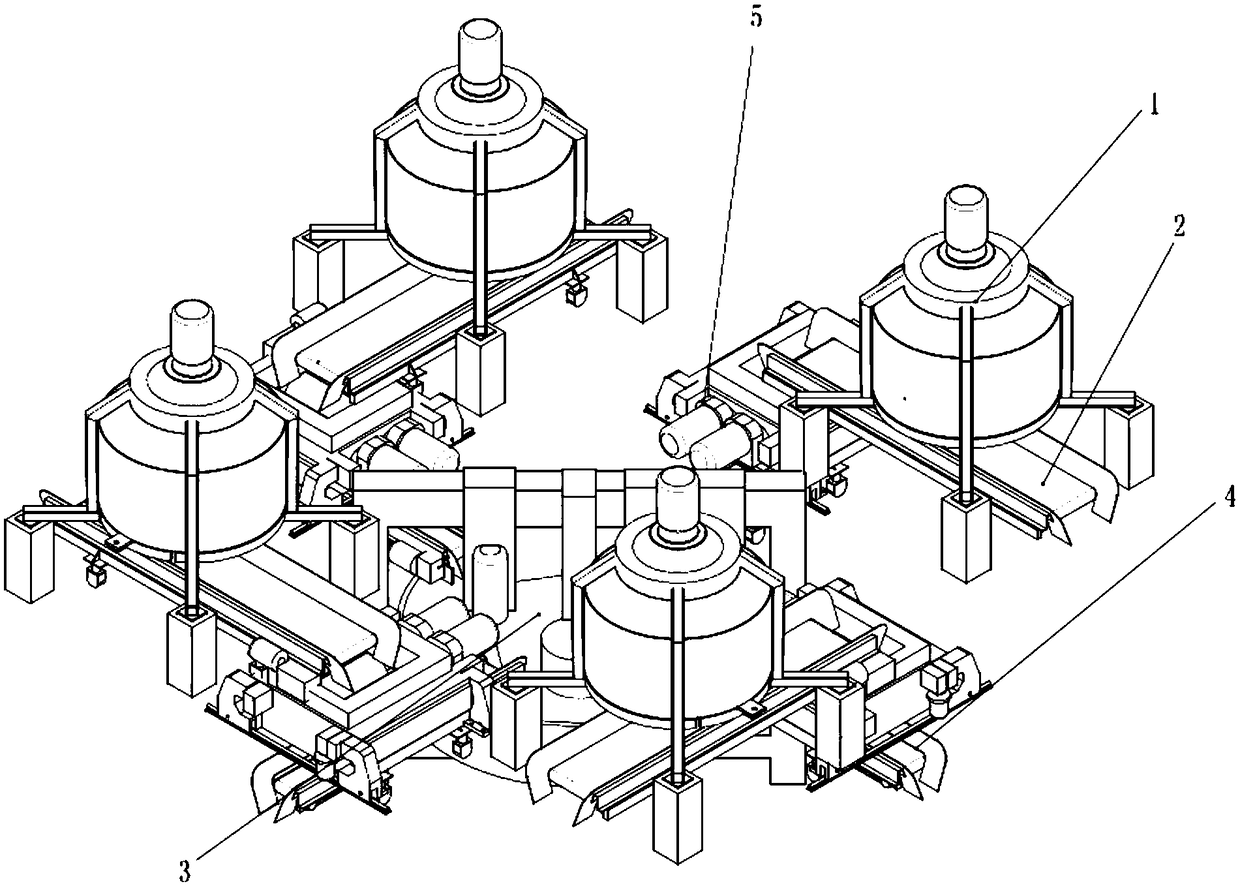

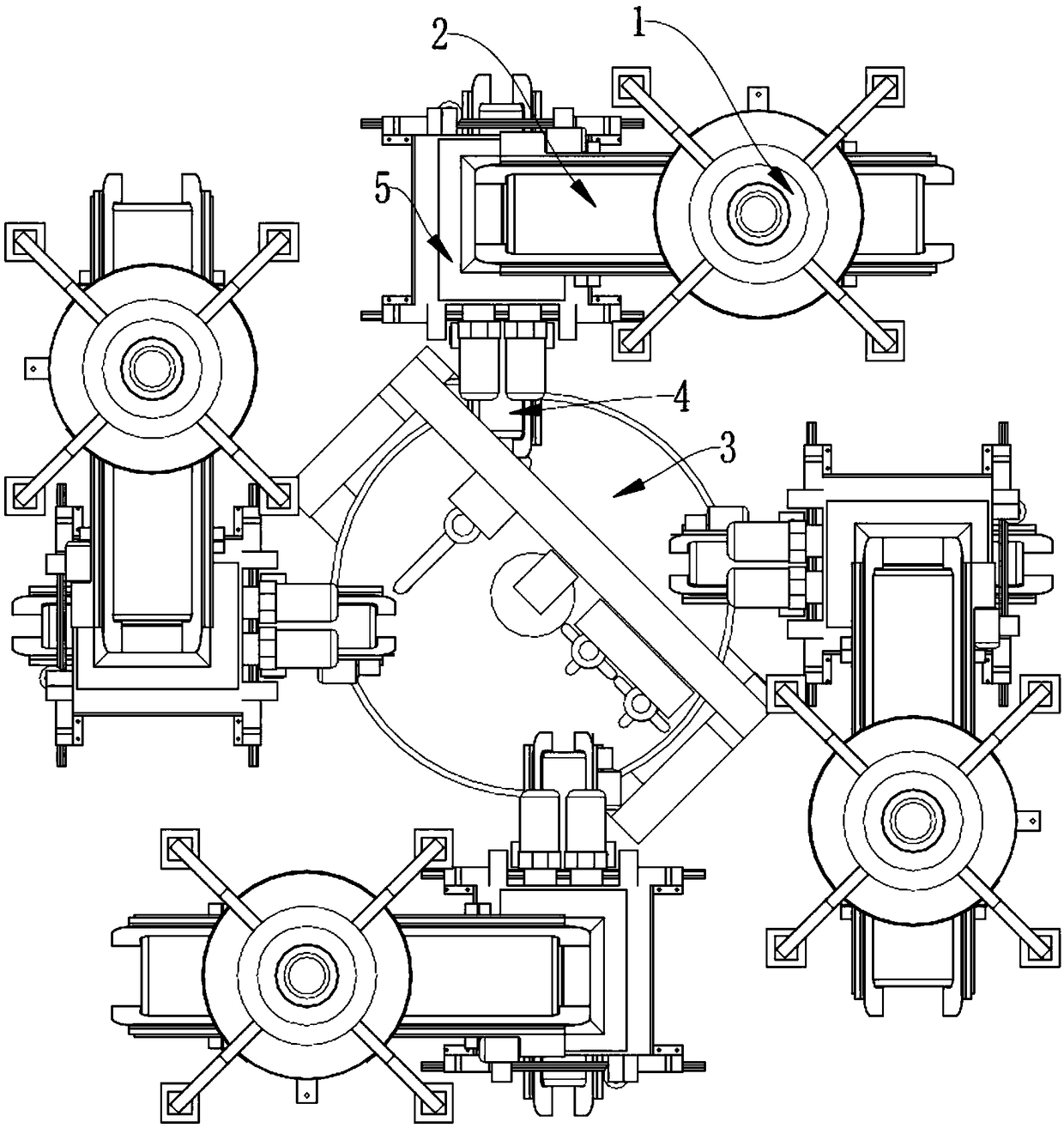

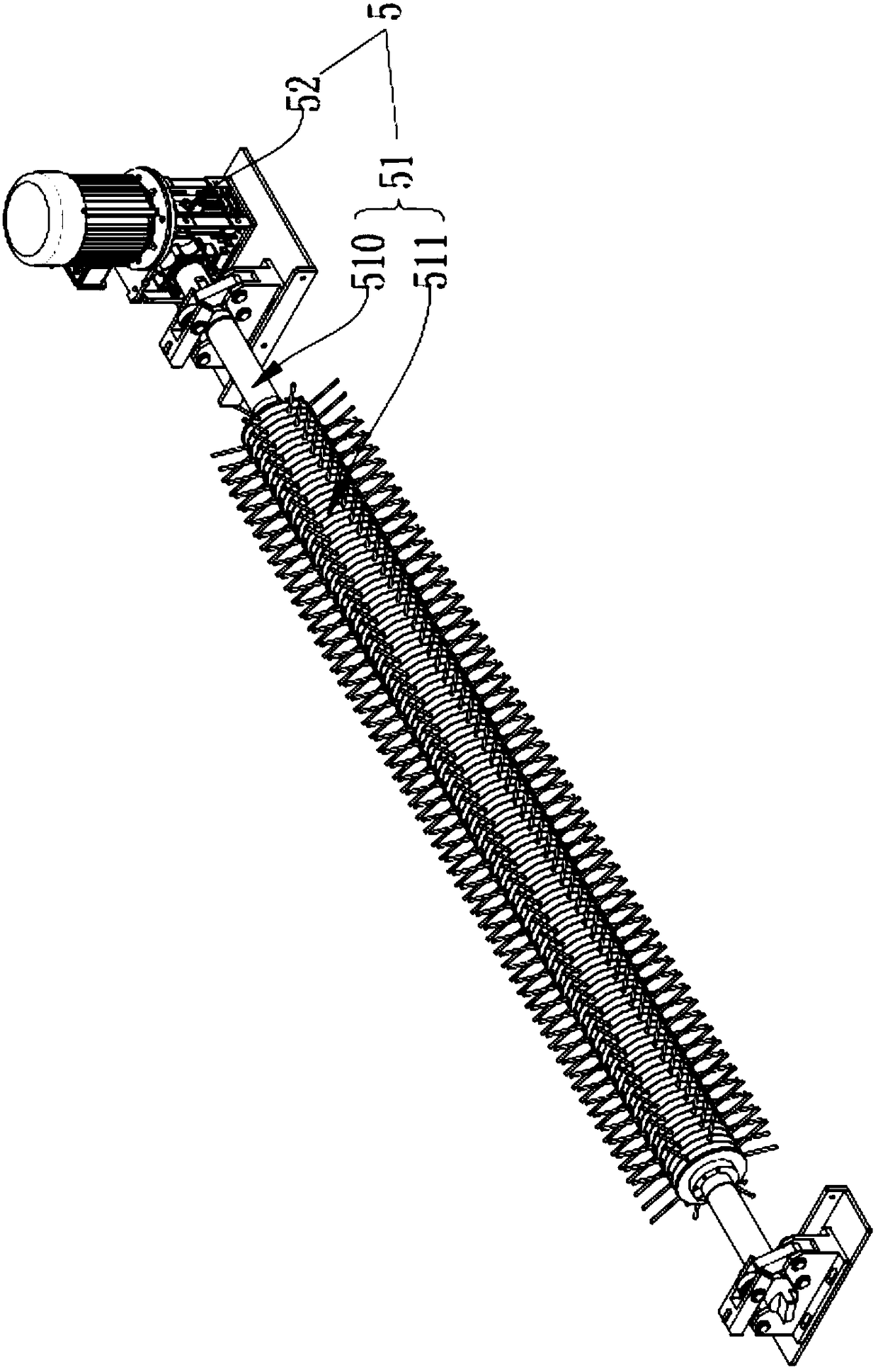

[0027] Such as figure 1 and figure 2 As shown, a production equipment for manufacturing products in the form of plates or blocks; including an initial mixer 1, a primary conveyor belt 2 and a mixing mixer 3;

[0028] Each initial mixer 1 is equipped with a primary conveyor belt 2, and one or more stones or granular materials similar to stones with a selected particle size and a binder are initially mixed in the initial mixer 1 to obtain an initial mixture. , the mixing mixer 3 includes a rotating container for receiving materials, and the initial mixture is transported to the mixing mixer 3 through the primary conveyor belt 2; more than one primary mixer 1 and its supporting primary conveyor belt 2 are arranged around the interval Around the mixing mixer 3.

[0029] Various initial mixtures with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com