Low temperature rise excitation electric generator and low temperature rise excitation electric motor

A generator, low temperature technology, applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of generators and motors, such as heating, to reduce failures, reduce energy loss, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

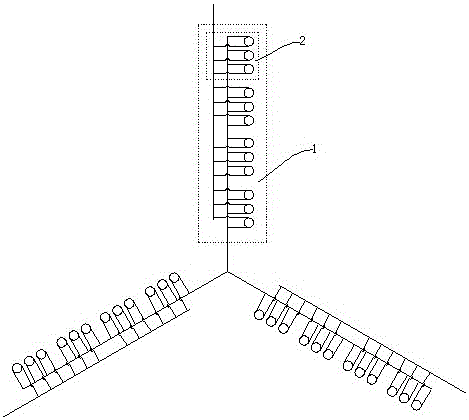

[0013] like figure 1 As shown, a low-temperature excitation generator described in this embodiment includes a rotor and a stator, and the stator includes three windings 1, each winding 1 is composed of four composite coils 2 in parallel, and the adjacent composite coils 2 are connected in parallel. The coils in the composite coil 2 are connected in the same direction from the end to the end, and the coils in the three windings 1 are connected in the same way; between the three windings 1 One of the corresponding parallel lines is connected at 120°, and the other parallel line is used as three output ends; the above-mentioned rotor is the existing rotor of the generator.

[0014] In order to achieve the rated output voltage and output current, the wire diameter of the composite coil 2 in the winding 1 is 1 / 4 of the existing standard, and the number of turns of each composite coil 2 is 4 times the existing standard; the above standard is the rated voltage The wire diameter and ...

Embodiment 2

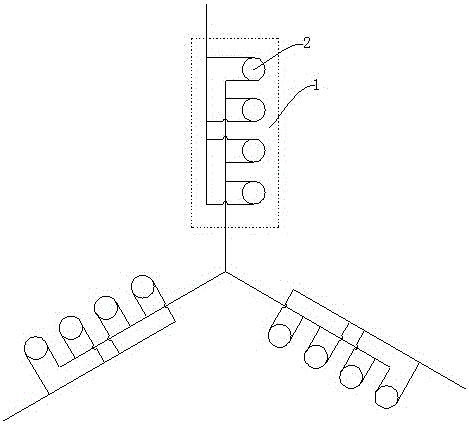

[0016] like figure 2 As shown in the figure, a low-temperature lift excitation motor described in this embodiment includes a rotor and a stator, and is characterized in that: the stator includes three windings 1, and each winding 1 is composed of four composite coils 2 in parallel, and adjacent composite coils 2 are formed in parallel. The coils 2 are connected in reverse from end to end, wherein each composite coil 2 is a coil, and the connection method of the coils in the three windings 1 is the same; the three windings 1 are connected at 120° through one of the corresponding parallel lines, and the other A parallel line serves as the three input terminals; the above-mentioned rotor is the existing rotor of the motor.

[0017] In order to achieve the rated input voltage and output power, the wire diameter of the composite coil 2 in the winding 1 is 1 / 4 of the existing standard, and the number of turns of each composite coil 2 is 4 times that of the existing standard. The a...

Embodiment 3

[0019] A low-temperature lift excitation motor described in this embodiment has a rated power of 180W, runs at full load for 3.5 hours, the measured temperature is 54°C, and the ambient temperature is 28°C. It can be seen that the low temperature rise excitation motor of the present invention can effectively reduce the generation of heat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com