Ship all-vanadium redox flow battery galvanic pile module

An all-vanadium redox flow battery and stack technology, which is applied to fuel cells, fuel cell additives, fuel cell grouping, etc., can solve the problems of difficult heat dissipation, damage to electric pushers, limited power storage capacity, etc., and achieves a novel structure. , The effect of ensuring personal safety and strong power storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

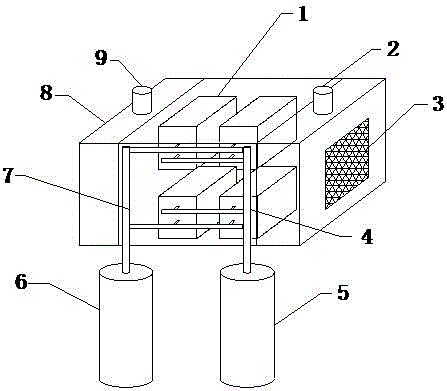

[0020] see Figure 1-Figure 3 , the present invention provides a technical solution: a marine all-vanadium redox flow battery stack 1 module, including the main body of the device, the stack 1 assembly, the all-vanadium liquid flow assembly and the heat dissipation mechanism 3, the main body of the device is composed of a box body 8, a positive electrode connection The positive terminal 9 and the negative terminal 2 are symmetrically installed on the upper end surface of the box body 8 .

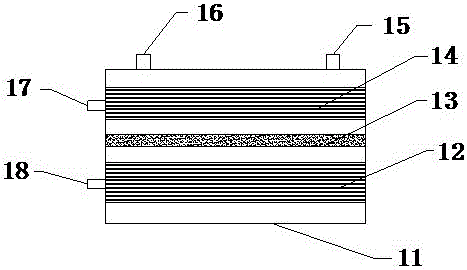

[0021] The stack 1 assembly is arranged in the box body 8. The stack 1 assembly is composed of four sets of stacks 1. The stack 1 consists of a casing 11, a negative plate 12, a diaphragm 13, a positive plate 14, a negative pole 15, and a positive pole 16. 1, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com