x-ray tube

An X-ray tube and lead wire technology, which is applied in the field of X-ray tubes, can solve the problems of the deterioration of the vacuum degree of the vacuum tube shell and the small detachment speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

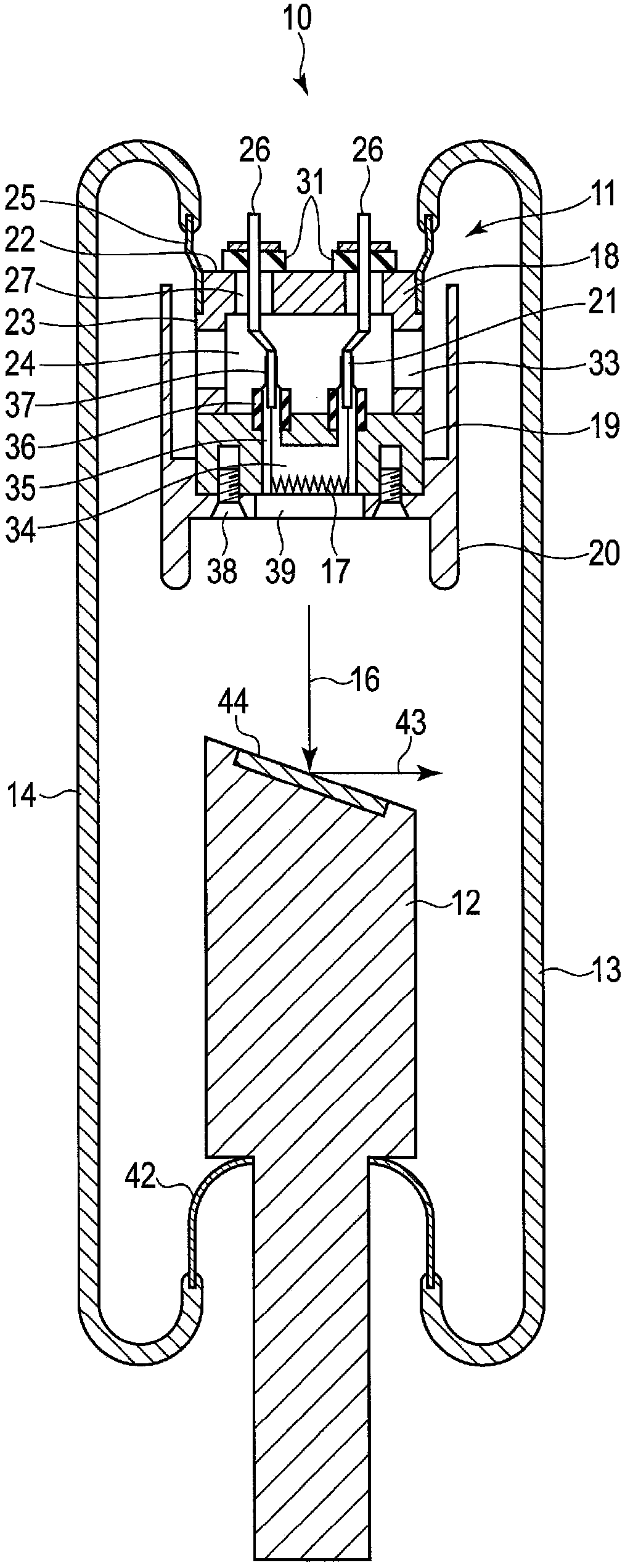

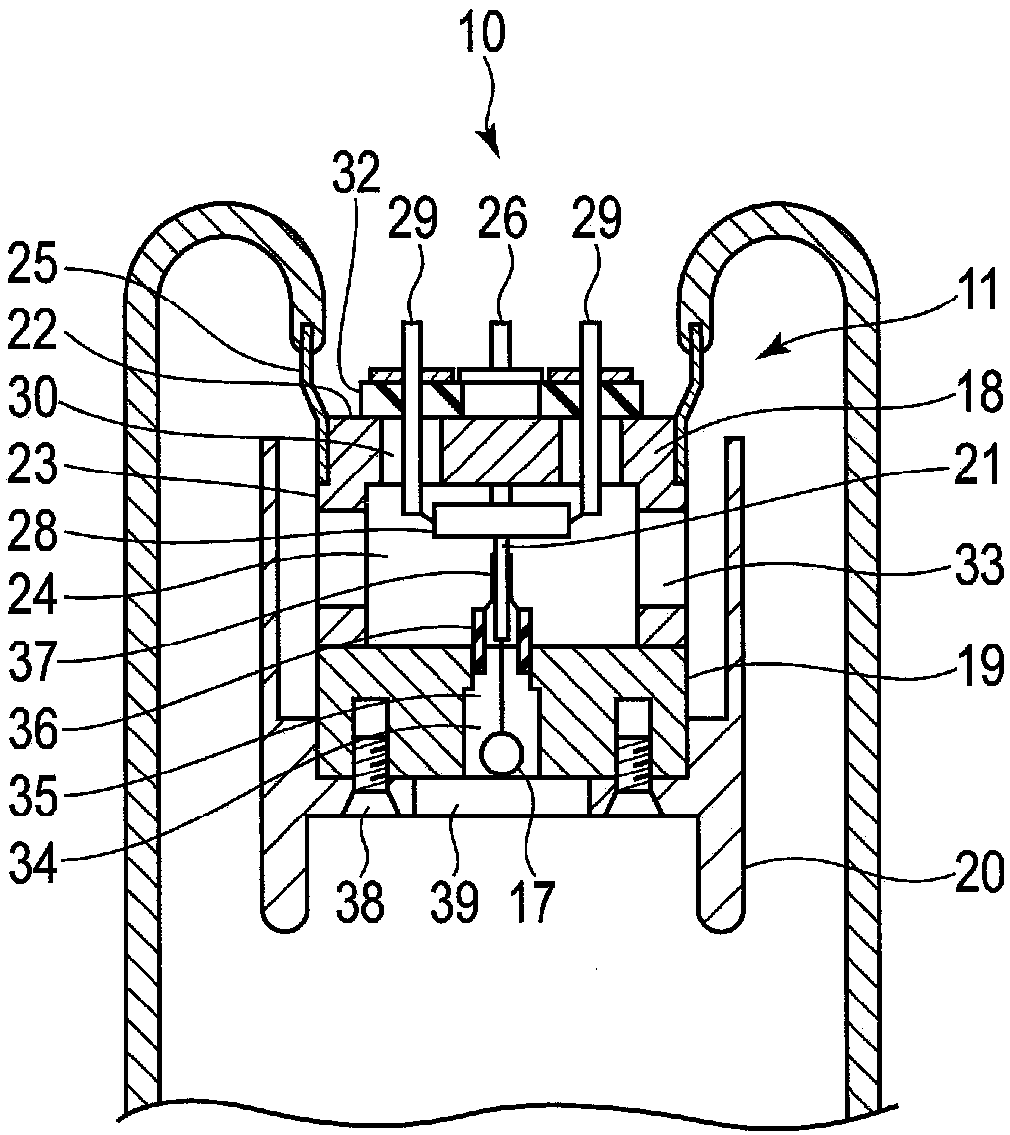

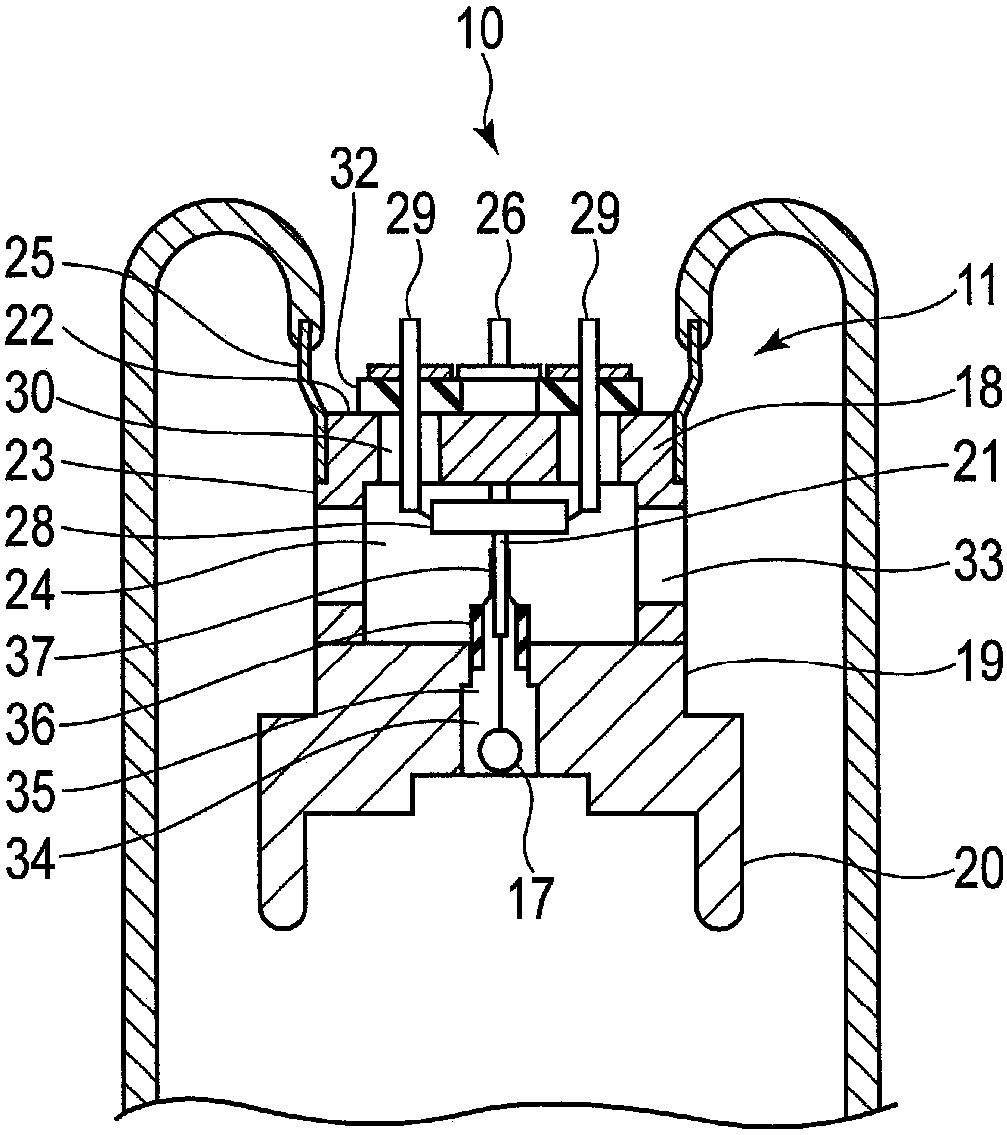

[0012] In summary, one embodiment provides an X-ray tube including: a cathode having a filament emitting an electron beam; an anode target injected into the electron beam to emit X-rays; and a vacuum envelope, The cathode and the anode target are housed inside the vacuum envelope. The cathode has a metal lead support body that constitutes a part of the vacuum envelope and is exposed to the outside of the vacuum envelope, and is attached such that a lead wire that supplies electricity to the filament passes through the vacuum enclosure. and a metallic filament support fixed to the lead support so as to contact the lead support and supporting the filament.

[0013] Below, refer to figure 1 and figure 2 The first embodiment will be described.

[0014] Such as figure 1 and figure 2 As shown, the X-ray tube 10 is a fixed anode type X-ray tube, and has a cathode 11, an anode target 12, and a vacuum envelope 13 that accommodates the cathode 11 and the anode target 12. The vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com