Optimal Design Method for Line Profile Before Track Laying

An optimization design and longitudinal section technology, applied in the field of line longitudinal section optimization design, can solve the problems of complex interrelationship, time-consuming and laborious, and complex optimization process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

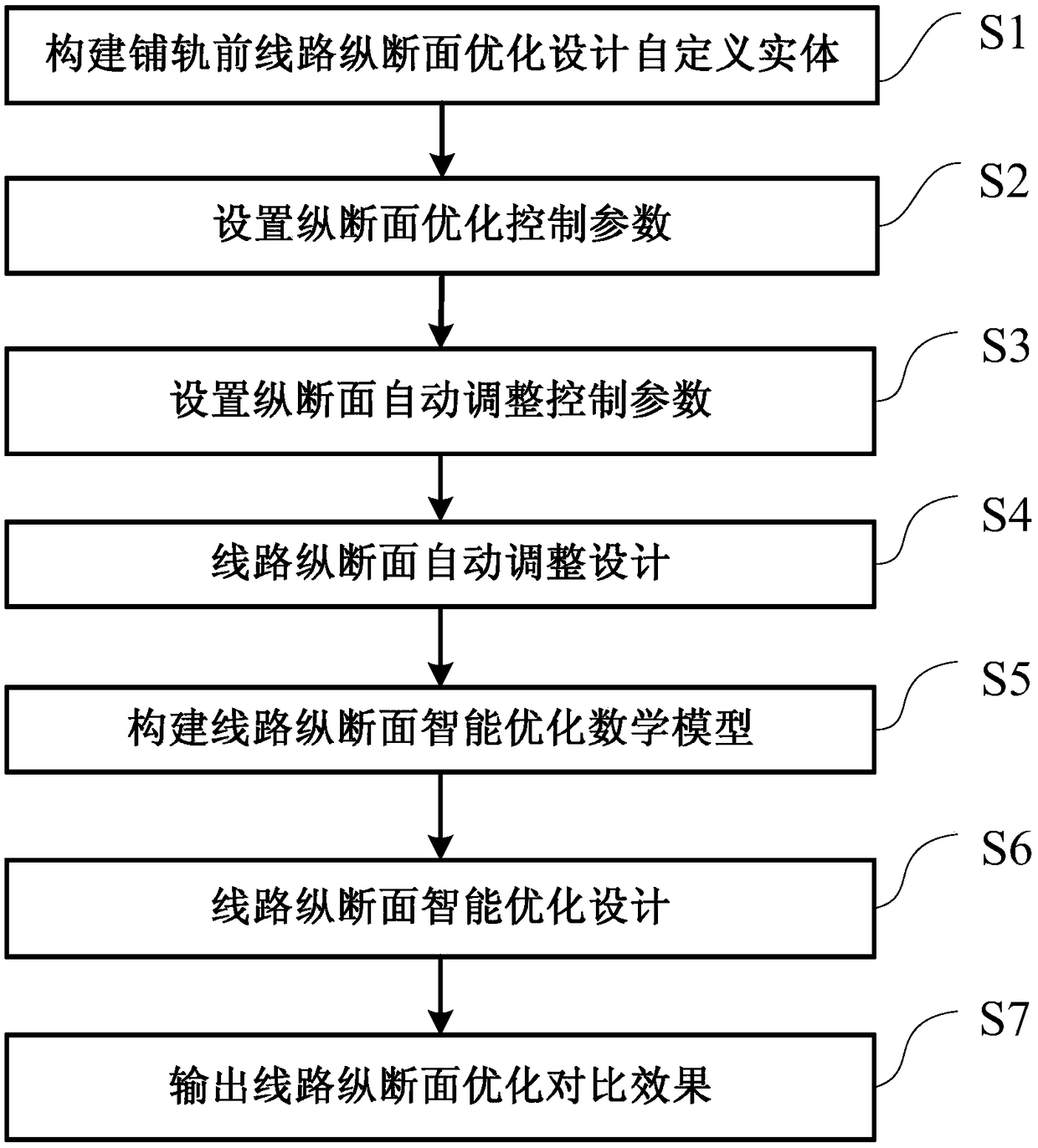

[0038] The specific technical solutions of the present invention are described with reference to the accompanying drawings. Depend on figure 1 As shown in the flowchart, the steps of the method for optimizing the design of the profile of the track before laying the track in the present invention include: constructing a self-defined entity for optimizing the design of the profile of the track before laying the track, setting the profile optimization control parameters, setting the profile automatic adjustment control parameters, the line Automatically adjust the design of the longitudinal section, build a mathematical model for intelligent optimization of the longitudinal section of the line, intelligently optimize the design of the longitudinal section of the line, and output the comparison effect of the optimization of the longitudinal section of the line.

[0039] S1. Construct a custom entity for the optimal design of the line profile before track laying

[0040] The optim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com