Imaging lens and imaging apparatus

A camera lens and lens technology, applied in instruments, subcutaneous biometrics, computing, etc., can solve the problem of small shooting magnification and achieve the effect of large shooting magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

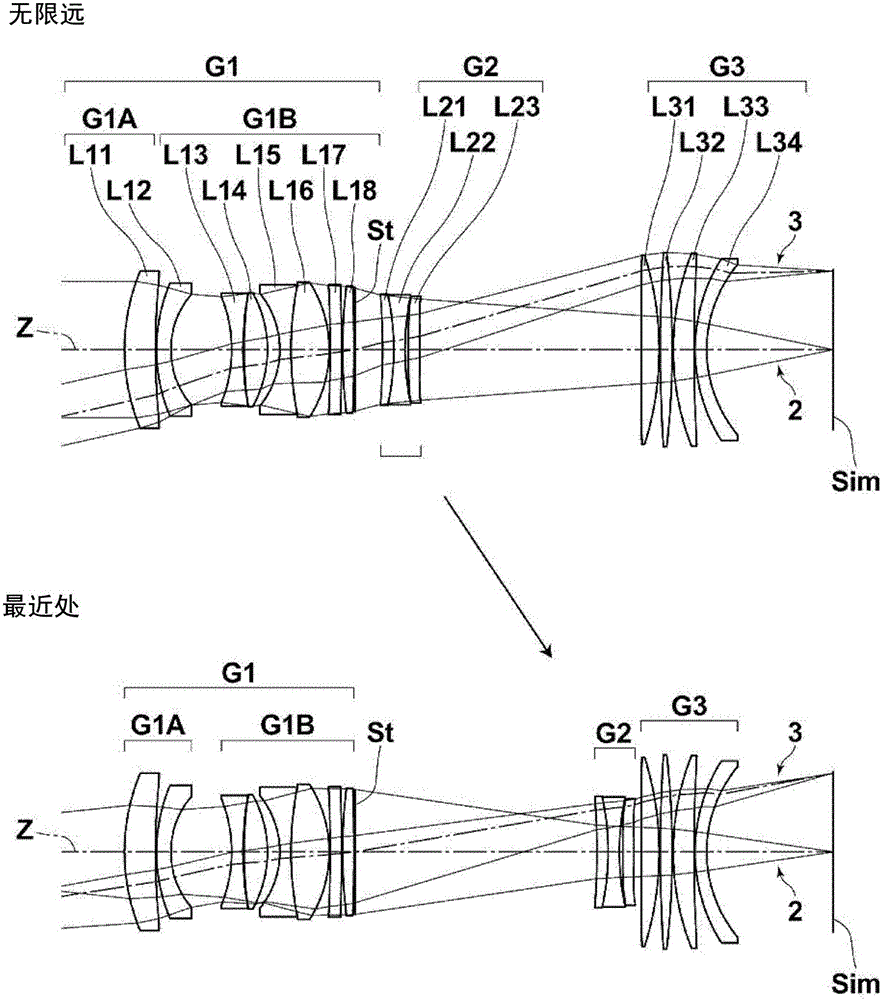

[0190] figure 1 The lens structure and optical path of the imaging lens of Example 1 are shown, and the illustration method is as described above, so repeated descriptions are omitted here. The imaging lens of Example 1 is composed of a first lens group G1 having positive refractive power, an aperture stop St, a second lens group G2 having negative refractive power, and a third lens group having positive refractive power in order from the object side. G3 composition. The focusing group is only the second lens group G2, and when focusing from an object at infinity to the nearest object, the second lens group G2 moves to the image side. It should be noted that the three-group structure mentioned here, the sign of the refractive power of each lens group, and the method of focusing are also the same for the imaging lenses of Examples 2 to 6 described later.

[0191] In the imaging lens of Example 1, the first lens group G1 is composed of the first lens group front group G1A and the ...

Embodiment 2

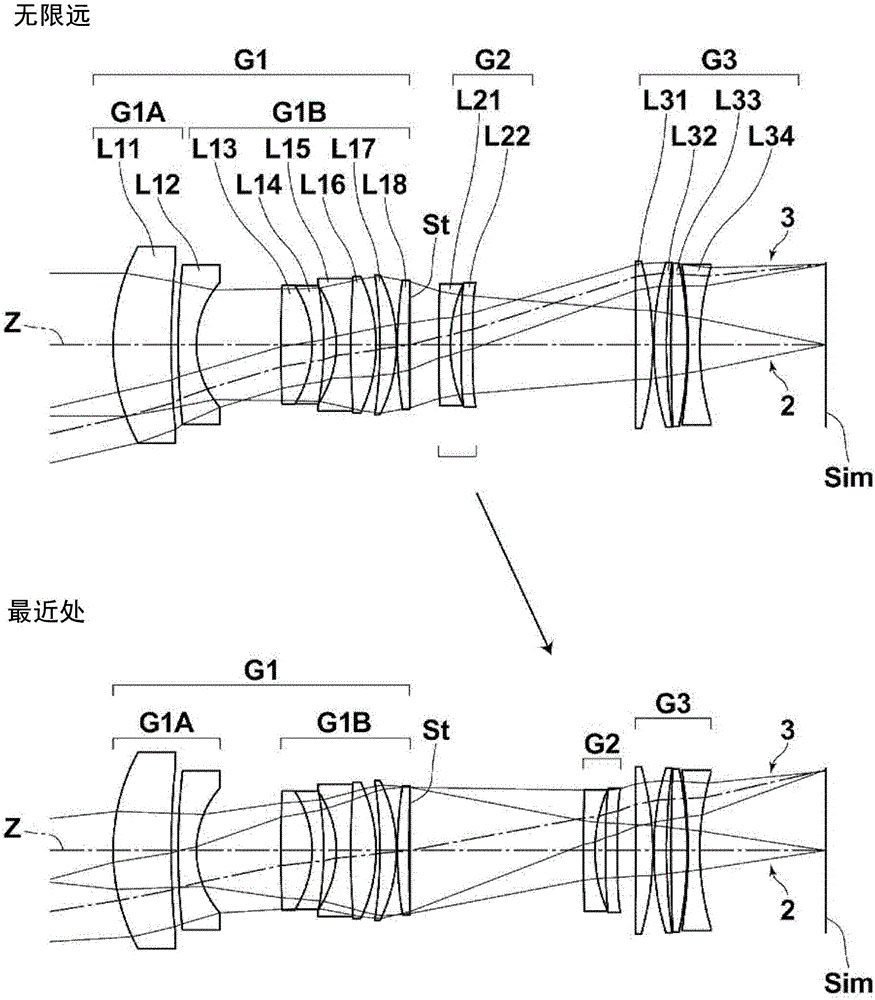

[0215] figure 2 The lens structure and optical path of the imaging lens of Example 2 are shown. In the imaging lens of Example 2, the first lens group G1 is composed of the first lens group front group G1A and the first lens group rear group G1B in order from the object side, and the first lens group front group G1A is composed of Lenses L11 to L12 are composed of two lenses. The first lens group rear group G1B is composed of six lenses L13 to L18 in order from the object side, and the second lens group G2 is composed of lenses L21 to L22 in order from the object side. The third lens group G3 is composed of four lenses of lenses L31 to L34 in order from the object side. Table 4 shows basic lens data of the imaging lens of Example 2, Table 5 shows aspheric coefficients, and Table 6 shows values of various factors and variable surface intervals. Figure 8 Various aberration diagrams of the imaging lens of Example 2 are shown.

[0216] 【Table 4】

[0217] Example 2

[0218] Si ...

Embodiment 3

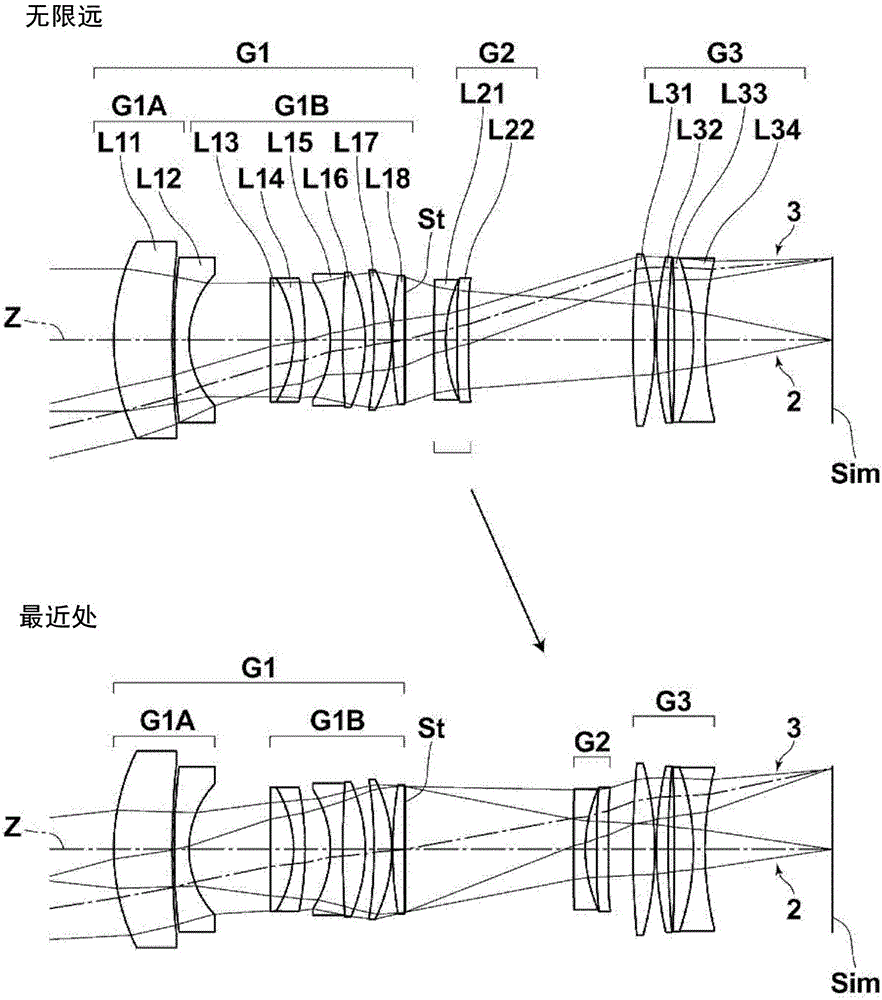

[0226] image 3 The lens structure and optical path of the imaging lens of Example 3 are shown. In the imaging lens of Example 3, the first lens group G1 is composed of the first lens group front group G1A and the first lens group rear group G1B sequentially from the object side, and the first lens group front group G1A is composed of Lenses L11 to L12 are composed of two lenses. The first lens group rear group G1B is composed of six lenses L13 to L18 in order from the object side, and the second lens group G2 is composed of lenses L21 to L22 in order from the object side. The third lens group G3 is composed of four lenses of lenses L31 to L34 in order from the object side. Table 7 shows the basic lens data of the imaging lens of Example 3, Table 8 shows aspheric coefficients, and Table 9 shows the values of various factors and variable surface intervals. Picture 9 Various aberration diagrams of the imaging lens of Example 3 are shown.

[0227] 【Table 7】

[0228] Example 3

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com