An update method for trenchless bendable pipelines

An update method, non-excavation technology, applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems that the pipeline does not meet the design and use requirements, and cannot realize the bending along with the bend, etc., to achieve Effects of improving adaptability and convenience and reducing construction equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for updating a non-excavation bendable pipeline, which includes the following steps:

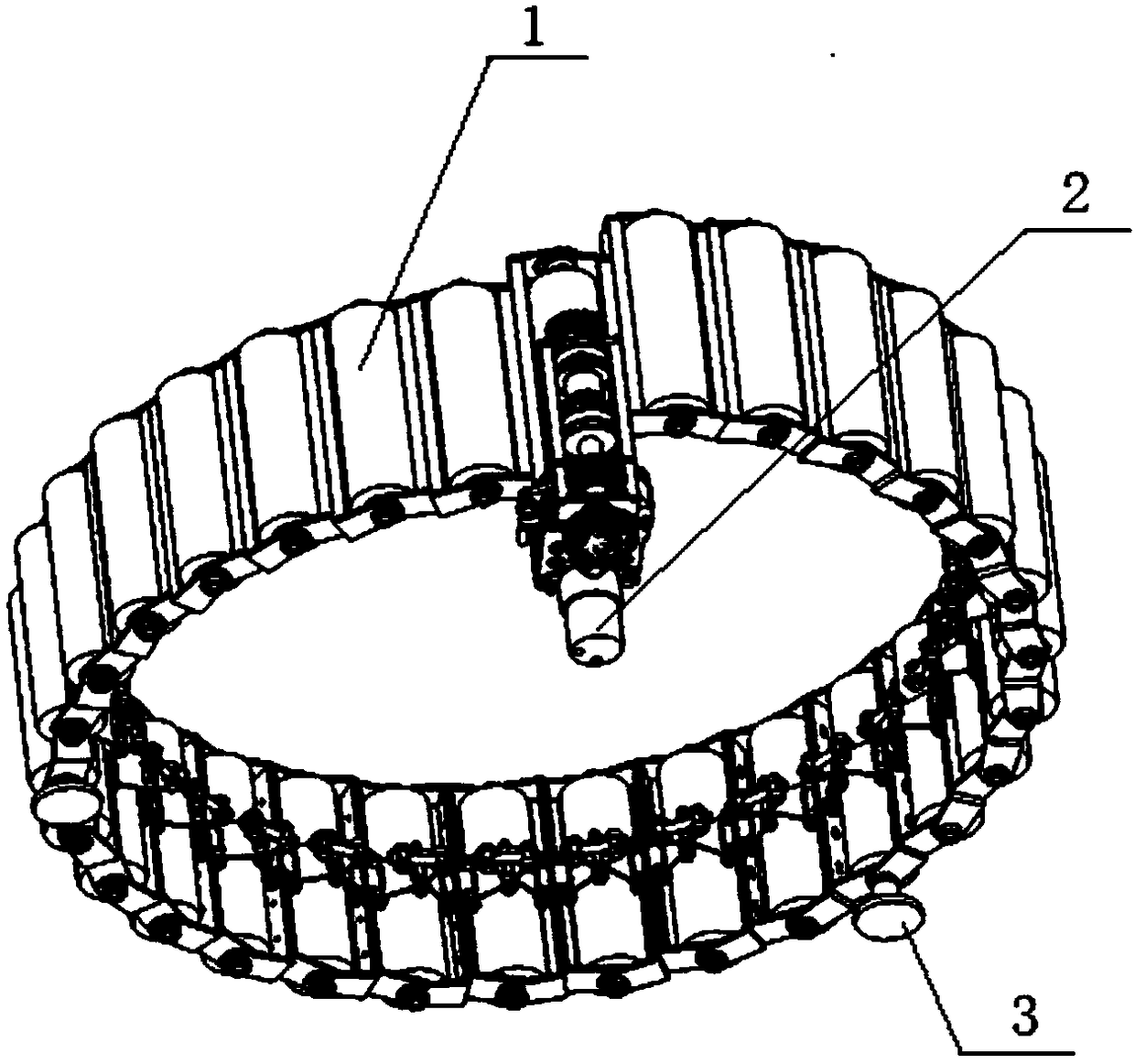

[0046] 1). Install a spiral new pipeline in the old underground pipeline or culvert that needs to be repaired. The new spiral pipeline is wound into a spiral shape by using a bendable strip profile 4 through a follow-up spiral winding machine;

[0047] 2). Pour mortar between the old underground pipe and the new spiral pipe.

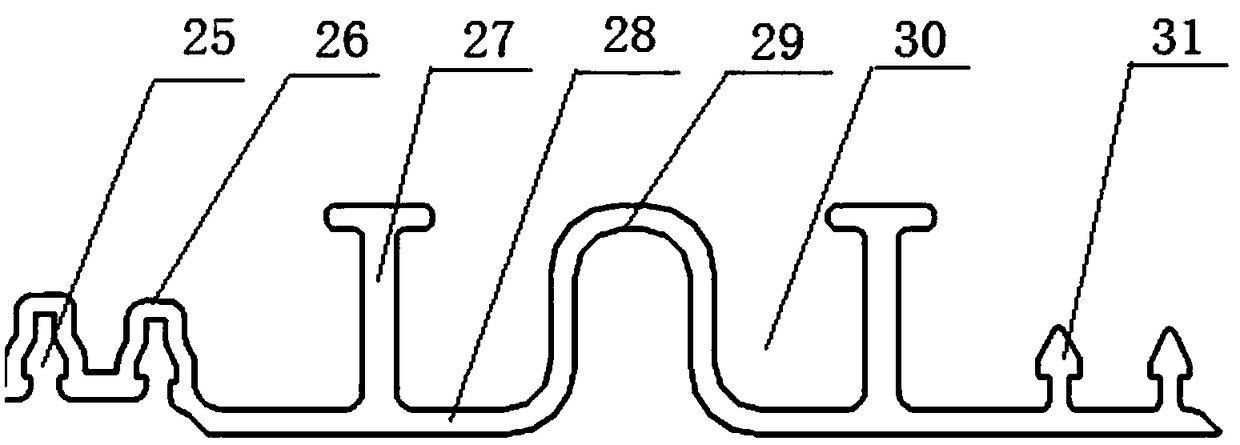

[0048] Such as figure 1 As shown in , the bendable strip profile is composed of a profile body 28, a lock slot 25, a lock head 31, a reinforcing rib 27, and a bending portion 29, and an upwardly convex lock is formed on one end of the profile body in the width direction. The other end in the width direction of the profile body is formed with an upwardly protruding locking clip, and the middle part of the profile body is formed with an upwardly protruding reinforcing rib. The lock card slots are two side by side lock card slots, and the lock card heads...

Embodiment 2

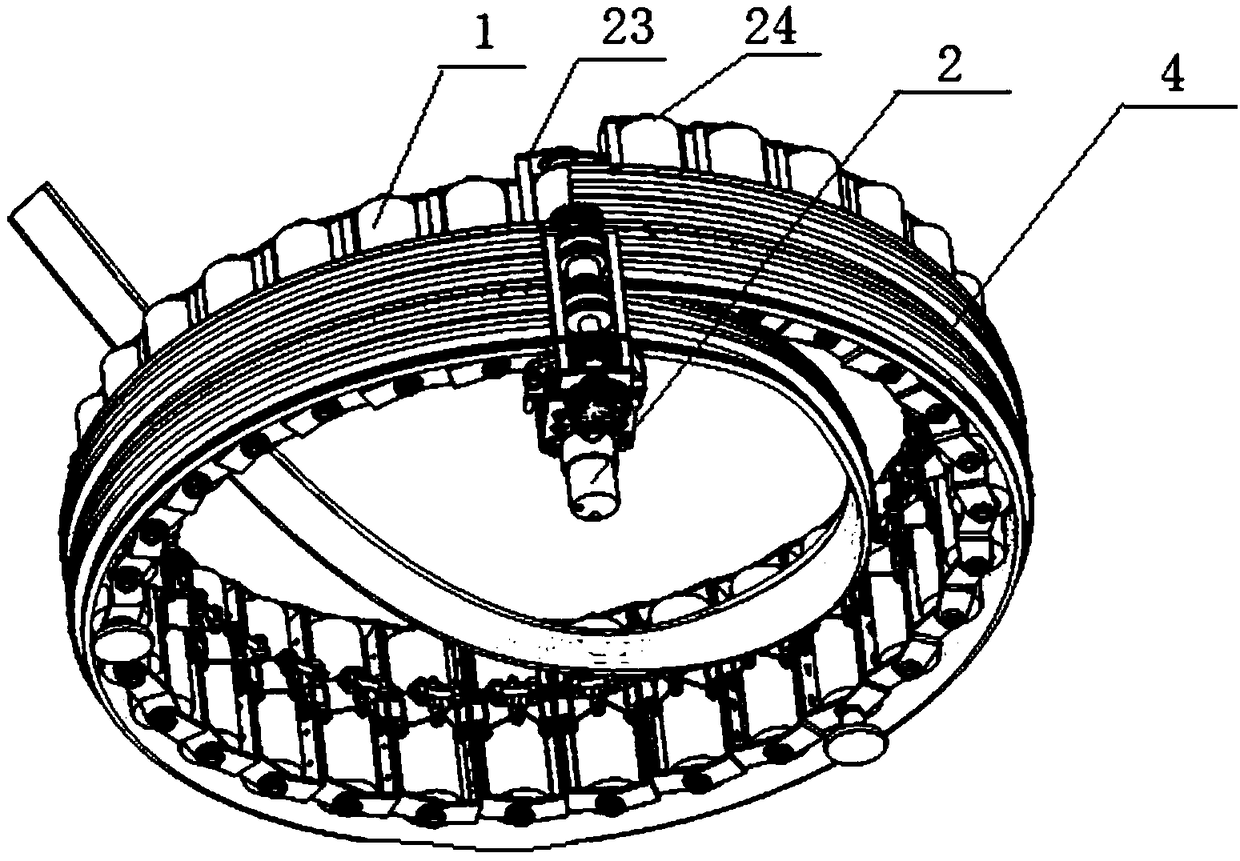

[0055] Such as Figure 6 , 7 shown. The follow-up spiral winding machine can be a follow-up winding machine with a guide rail. The structure of the follow-up winding machine with a guide rail is: including a support guide rail 32, a roller chain ring 33 with a guide wheel and a drive assembly, and a roller chain with a guide wheel. The ring is composed of multiple chain roller units connected end to end to form a ring. The chain roller unit is mainly composed of chain roller 5, chain link 6, guide wheel 36 and guide wheel frame 34. The chain links are hinged symmetrically on both radial sides of the chain roller. These two chain link bottoms are hinged guide wheel frame, and guide wheel frame bottom is installed guide wheel by guide wheel axle 35. The bottom of the guide wheel frame is equipped with two guide wheels symmetrically through the guide wheel axis. The inner sides of the two guide wheels are rolled on the guide rail. The guide rail is a plate guide rail. Since th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com