Bilateral two-stage internal engagement biarc bevel gear nutation speed reducer and working method

A technology of bevel gear transmission and double circular arc, which is applied in the direction of gear transmission, belt/chain/gear, transmission, etc., can solve the problems of increased noise, radial interference, heavy weight, etc., and achieve the overall service life extension, Reasonable structural design and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

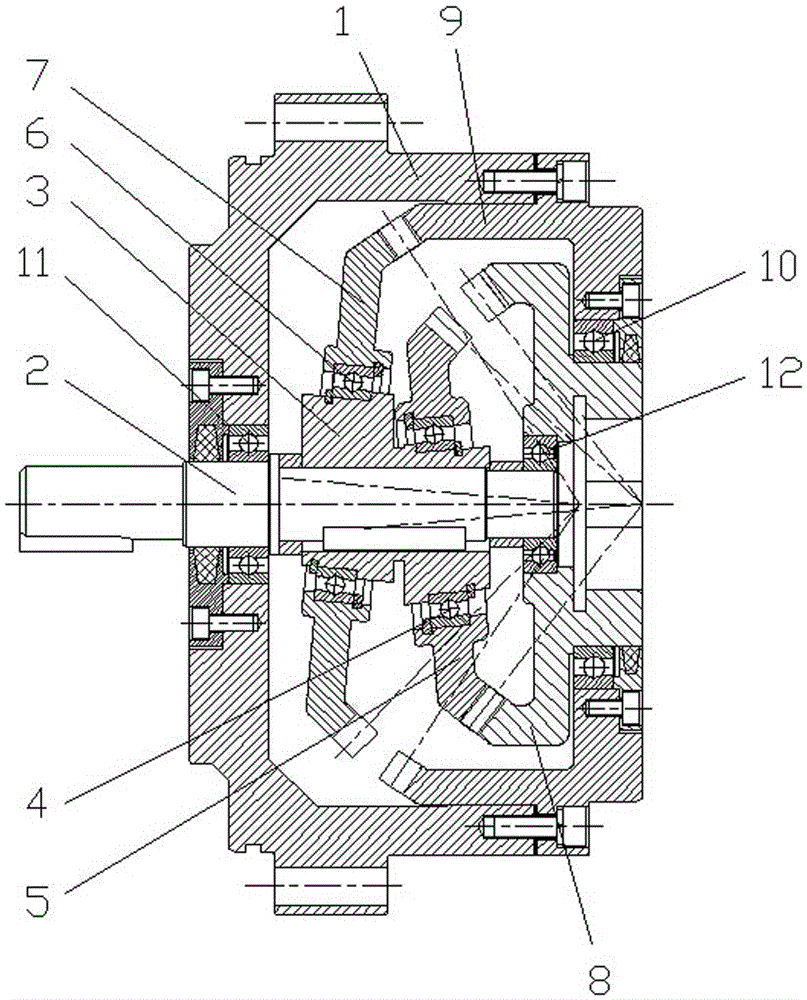

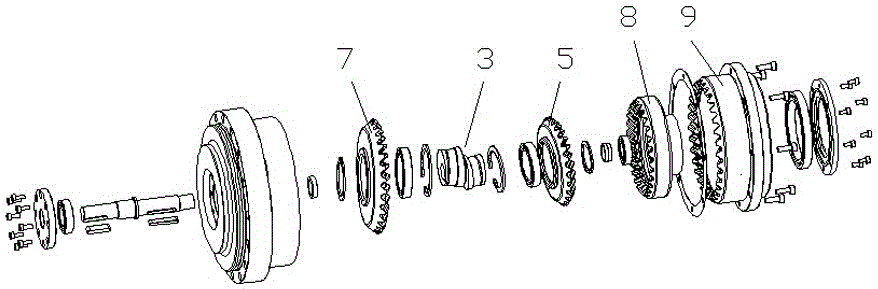

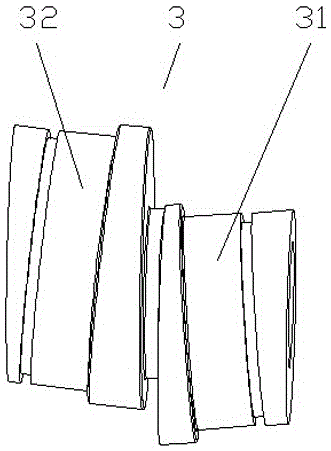

[0022] Such as Figure 1~4 As shown, a double-sided double-stage internal meshing double-arc bevel gear nutation reducer includes a box body 1, and one end of the box body 1 is pierced with an input shaft 2, and the input shaft 2 is located in the box body 1 A nutating sleeve 3 is arranged on the shaft section of the nutating sleeve 3, and a variable-speed double-arc bevel gear 5 is connected to the nutating sleeve 3 via the first bearing 4, and a balance double-arc bevel gear 5 is connected to the nutating sleeve 3 via the second bearing 6. Arc bevel gear 7, the other end of the box 1 is provided with output double arc bevel gear 8 and fixed double arc bevel gear 9, the output double arc bevel gear 8 and fixed double arc bevel gear 9 The third bearing 10 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com