Cylindrical workpiece printing and packaging machine

A cylindrical workpiece and integrated machine technology, which is applied to the field of cylindrical workpiece printing and packaging integrated machines, can solve the problems that the cylindrical workpiece cannot be automatically packaged and cannot be printed on the surface of small circular workpieces, and achieves saving labor costs, compact structure, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

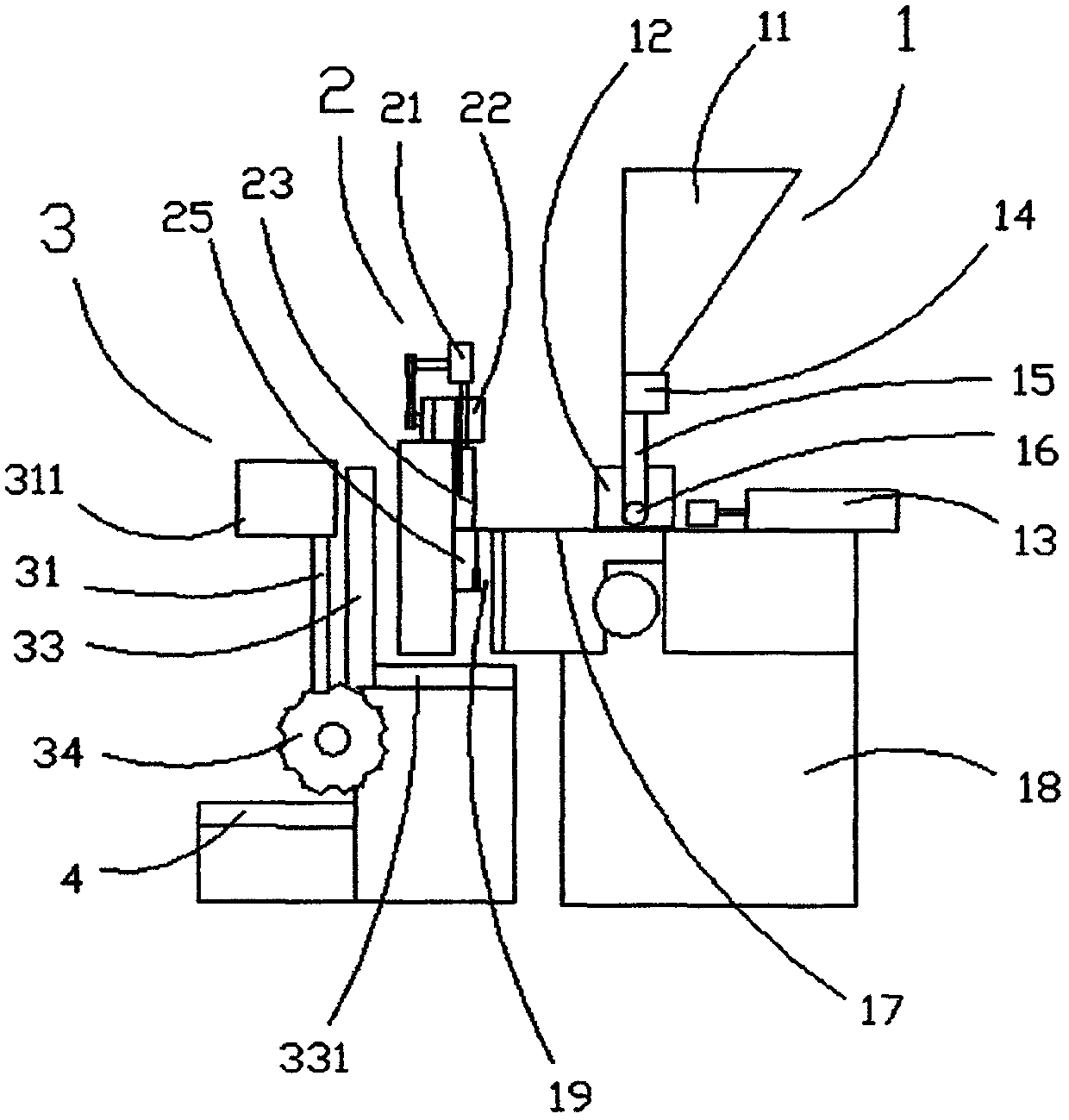

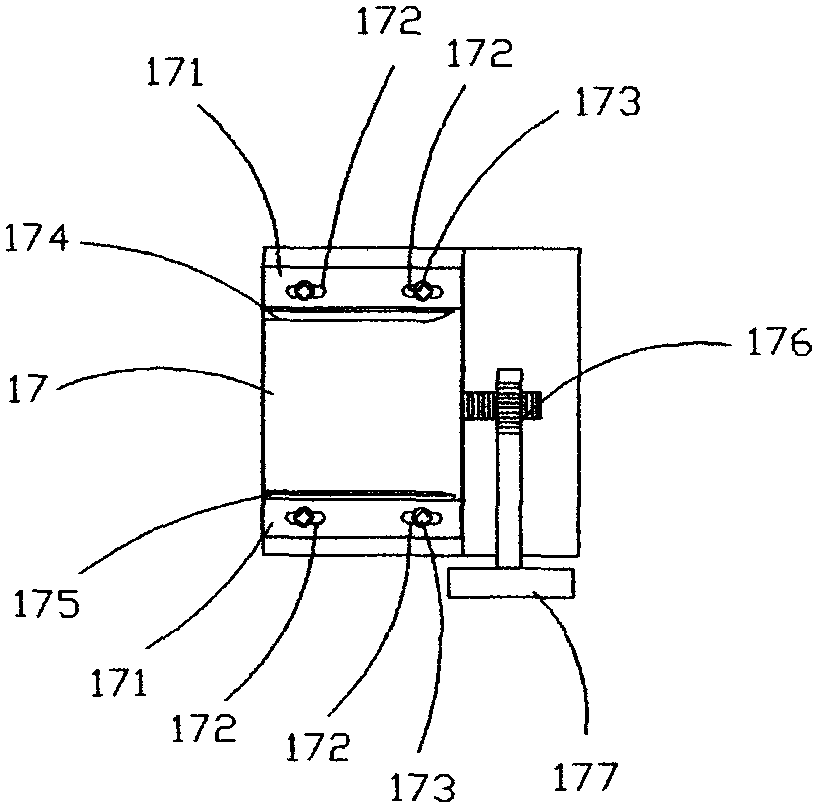

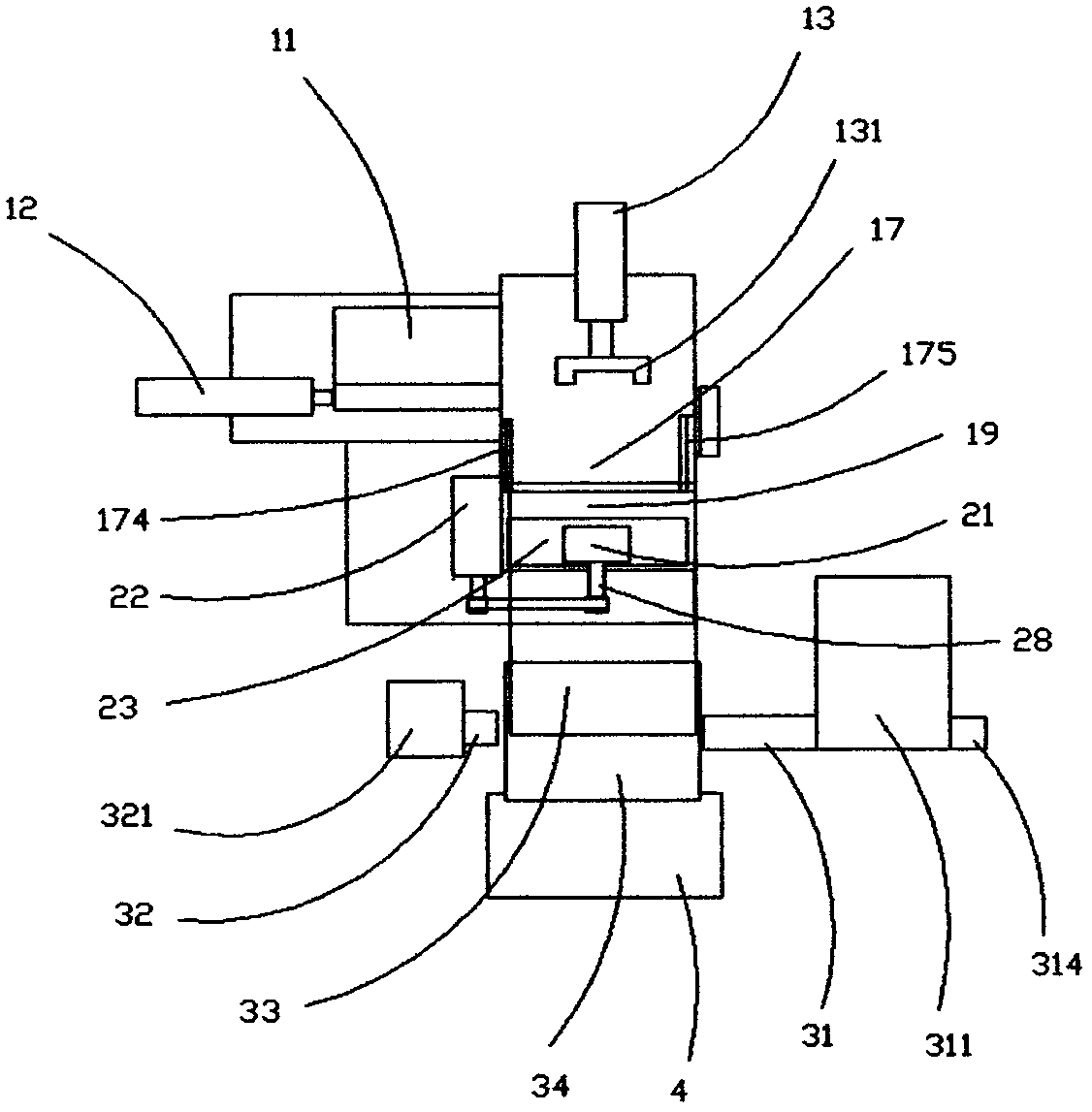

[0022] Such as figure 1 , 2 , 3, 4, and 8, a small cylindrical workpiece printing and packaging machine includes a feeding device 1, a sliding pressure device 2, and a packaging system 3. The feeding device 1 includes a machine base 18, a hopper 11, a power mechanism, and a machine. The feeding table 17 of the seat 18 is provided with two power mechanisms I13 and power mechanism II12 installed at right angles, and the top of the push rod of the power mechanism I13 is provided with a Π-type push piece 131, and the two top surfaces of the push piece 131 are connected to the The sliding and pressing surfaces on the outside of the feeding table 17 are parallel. The bottom of the hopper 11 is provided with a feeder 14, the discharge hole 16 on both sides of the lower material channel 15 is on the same axis as the push rod of the power mechanism II12, and the two sides of the feeding table 17 are provided with an adjustment stopper 174 and a spring stopper. plate 175, the sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com