Position changing structure of position changing door

A technology of sealing plate and pushing head, applied in the field of transposition structure of transposition door, can solve the problems of waste of human resources, low work efficiency, lack of control methods, etc., to avoid secondary pollution, improve efficiency, and save land use resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

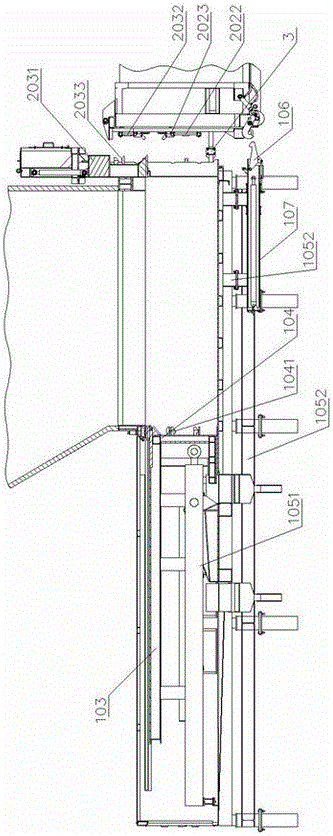

[0027] A transposition structure of a transposition door, which is characterized in that it includes: a push head 104 for transposition and a sealing plate 202 for transposition, the push head 104 is provided with a press for connecting with the sealing plate 202 Installer 1041, the sealing plate 202 is provided with a docking hole 2021 for docking with the presser 1041, the push head 104 is connected with the docking hole 2021 provided on the sealing plate 202 through the presser 1041 to form a Move the push plate of the push material to form the transposition structure of the transposition door.

[0028] Example 1:

[0029] A transposition structure of a transposition door, which is characterized in that it includes: a push head 104 for transposition and a sealing plate 202 for transposition, the push head 104 is provided with a press for connecting with the sealing plate 202 Installer 1041, the sealing plate 202 is provided with a docking hole 2021 for docking with the pre...

Embodiment 3

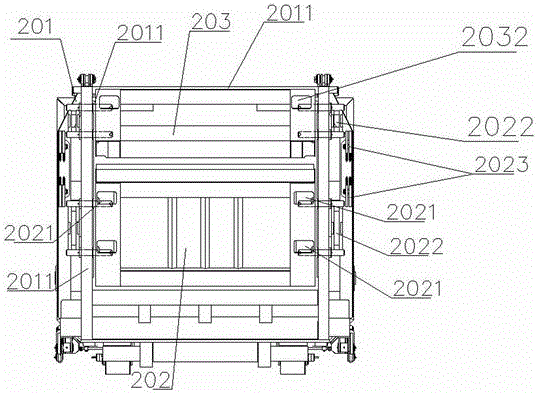

[0032] A transposition structure of a transposition door, which is characterized in that it includes: a push head 104 for transposition and a sealing plate 202 for transposition, the push head 104 is provided with a press for connecting with the sealing plate 202 Installer 1041, the sealing plate 202 is provided with a docking hole 2021 for docking with the presser 1041, the push head 104 is connected with the docking hole 2021 provided on the sealing plate 202 through the presser 1041 to form a Move the push plate of the push material to form the transposition structure of the transposition door.

[0033] The transposition structure of the transposition door also includes an upper sealing plate 203 capable of moving upwards and a lifting device 2031 for lifting the upper sealing plate 203. The upper sealing plate 203 is provided with a lifting hole 2032, and the lifting device 2031 is provided with a lifting hook 2033, and the lifting device 2031 is connected with the docking...

Embodiment 4

[0037] A transposition structure of a transposition door, which is characterized in that it includes: a push head 104 for transposition and a sealing plate 202 for transposition, the push head 104 is provided with a press for connecting with the sealing plate 202 Installer 1041, the sealing plate 202 is provided with a docking hole 2021 for docking with the presser 1041, the push head 104 is connected with the docking hole 2021 provided on the sealing plate 202 through the presser 1041 to form a Move the push plate of the push material to form the transposition structure of the transposition door.

[0038] The transposition structure of the transposition door also includes an upper sealing plate 203 capable of moving upwards and a lifting device 2031 for lifting the upper sealing plate 203. The upper sealing plate 203 is provided with a lifting hole 2032, and the lifting device 2031 is provided with a lifting hook 2033, and the lifting device 2031 is connected with the docking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com