Quick arranging, polishing and shaping-collecting equipment for formed openings

A technology for collecting equipment and cracks, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of labor-intensive, low efficiency, poor effect, etc., and achieve power saving, high quality and high-efficiency grinding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

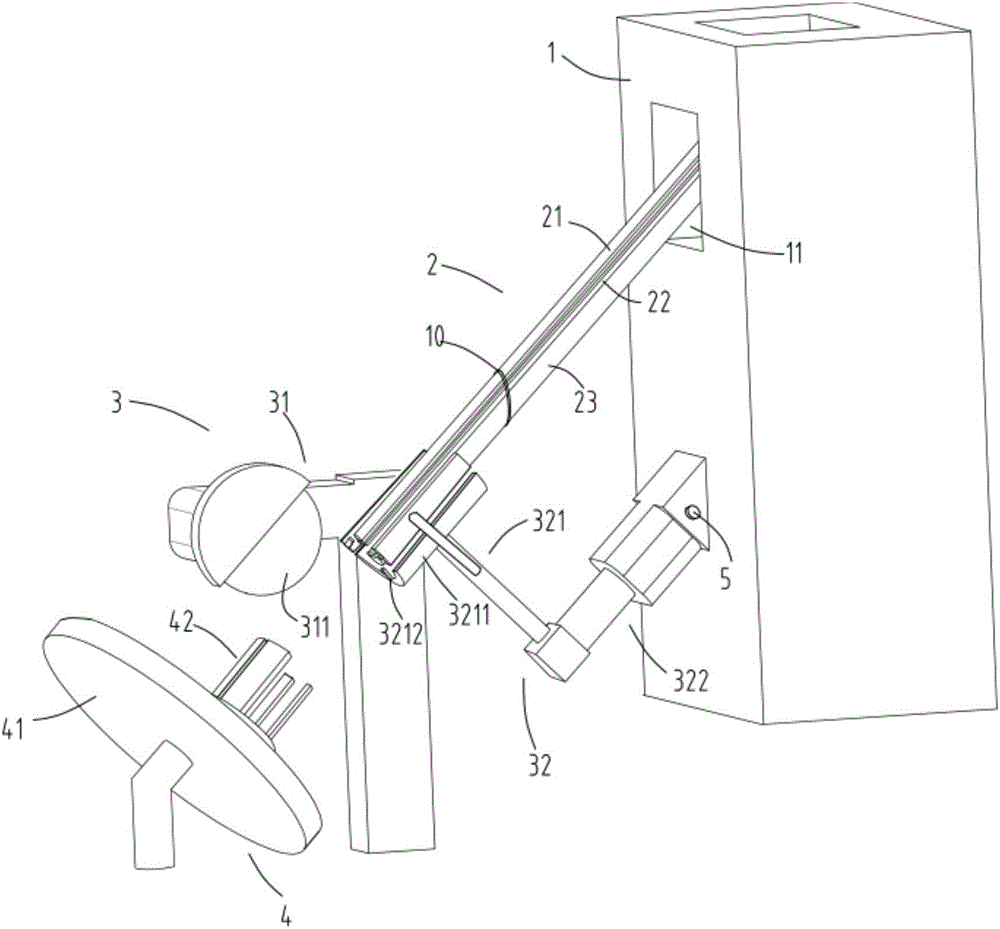

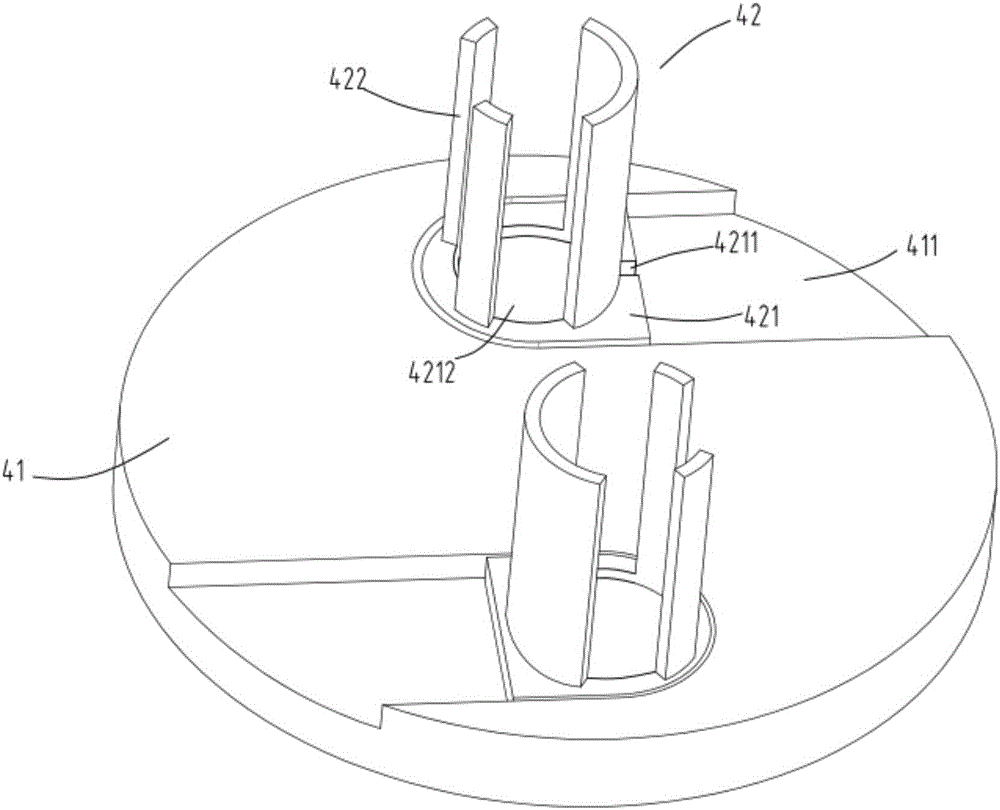

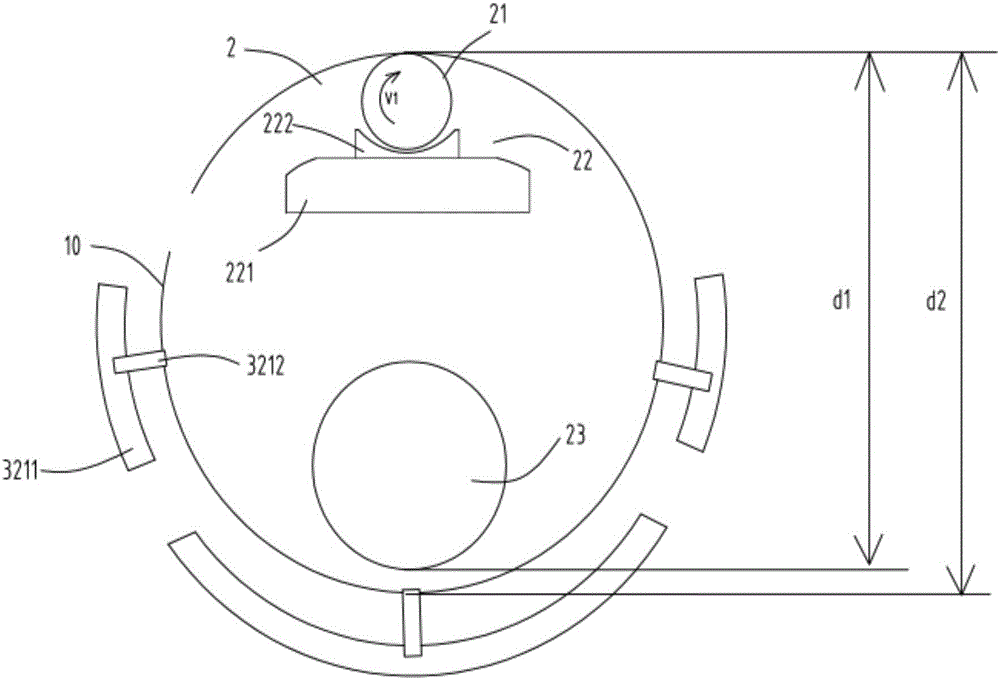

[0028] figure 1 It is a schematic diagram of the structure of a rapid arrangement, grinding and shaping collection equipment for breaches, figure 2 Schematic diagram of the structure of the stereotyped collection device, image 3 is a schematic cross-sectional view of the piston ring hanging on the blanking rod, Figure 4 It is a cross-sectional schematic diagram when the piston ring falls to the jammed part, Figure 5 Schematic diagram of the automatic alignment device. Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown in the figure, a device for quickly arranging, grinding, and shaping collection for breaks includes a breaker 1, an automatic arrangement device 2, a grinding device 3, and a shaped collection device 4; the automatic arrangement device 2 is arranged at the material outlet 11 of the breaker 1 place, used to neatly arrange the broken piston rings 10 in a straight line at the broken places; Grinding; the sizing collection device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com