Ultra-low emission type desulfurization and dust removal rotational flow tray jet tower

A technology of desulfurization and dust removal and spray tower, which is applied in the use of liquid separation agent, gas treatment, membrane technology, etc., can solve the problems of unsatisfactory users, technical parameter limitations, high operating costs, etc., and achieve small daily maintenance and high process reliability , the effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

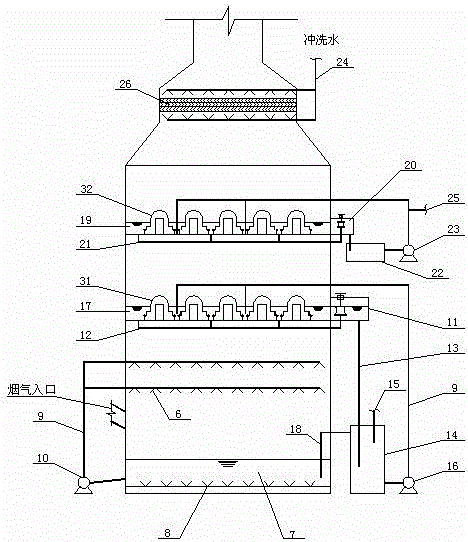

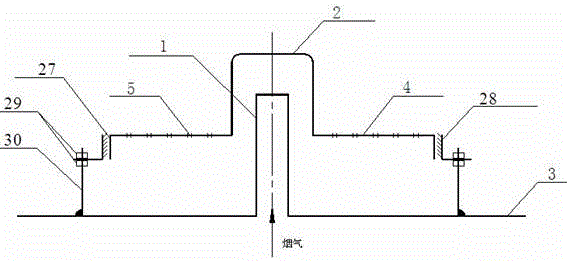

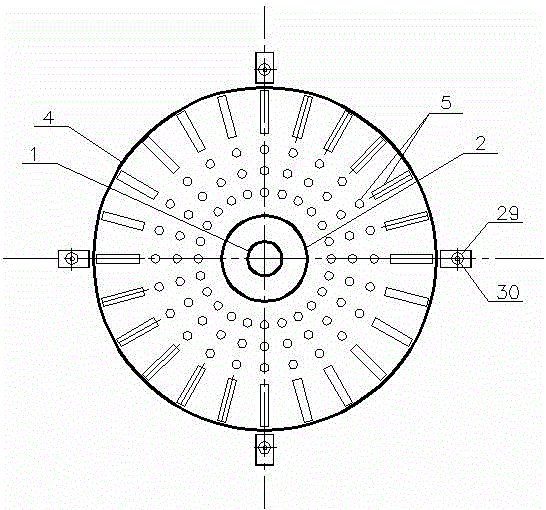

[0037]Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a desulfurization tower, and a spray system, a slurry swirl tray mixer 31, a clean water swirl tray mixer 32, and a demister are arranged in the desulfurization tower. The special feature is that the spray system is located at the lower part of the desulfurization tower. The demister is located on the upper part of the desulfurization tower, and the slurry swirl tray mixer 31 and the clean water swirl tray mixer 32 are arranged between the spray system and the demister. Slurry swirl tray mixer 31 comprises gas riser 1 and bubble cap 2, gas riser 1 is installed on the tray 3 of the desulfurization tower, gas riser 1 is covered with bubble cap 2, and tray 4 is arranged outside the bubble cap 2, the tray 4 and Blister 2 is connected, and baffle plate 27 is set under the edge of tray 4, and fixing member 28 is arranged outside baffle plate 27, and bolt 30 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com