Slide carriage brushing bristle buffering taper rotary drum type walnut pulp removing device with rotating speed monitored by computer

A technology of computer monitoring and sliding plate bristles, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of heavy workload, heavy weather influence, low efficiency, etc., to eliminate vibration and impact, reduce destructive impact, The effect of simple machine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will now be further described in detail with reference to the accompanying drawings.

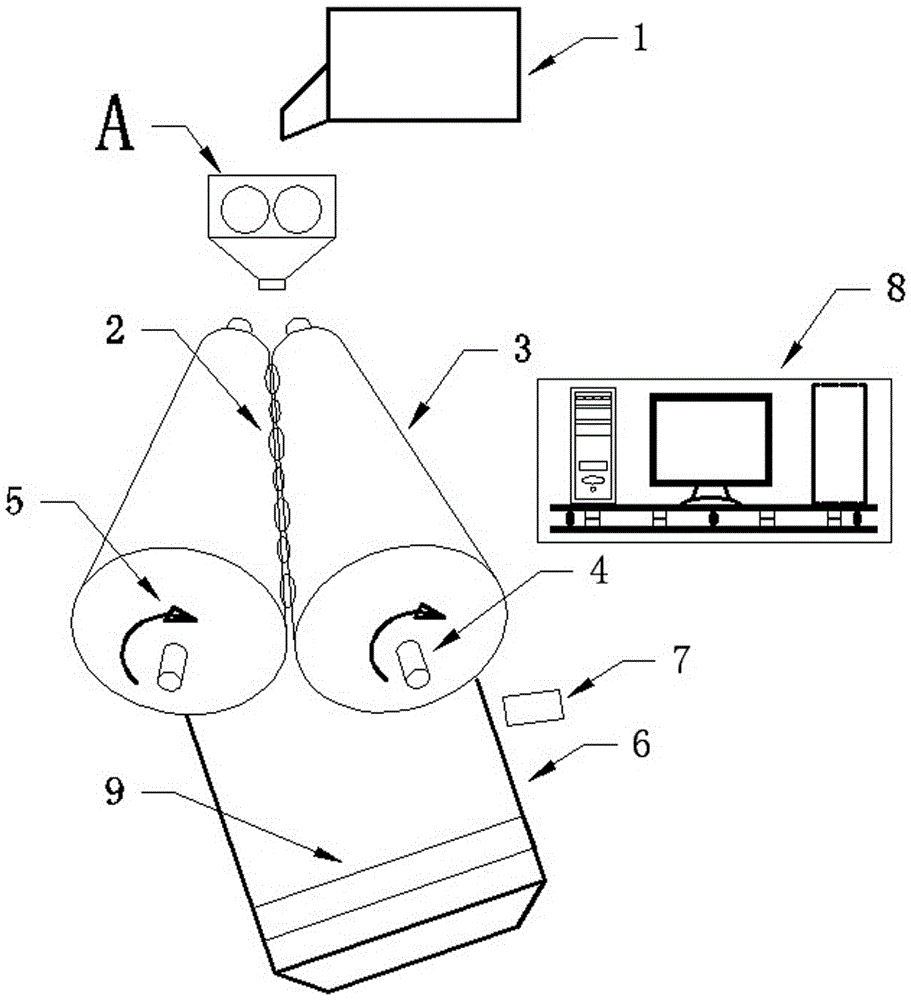

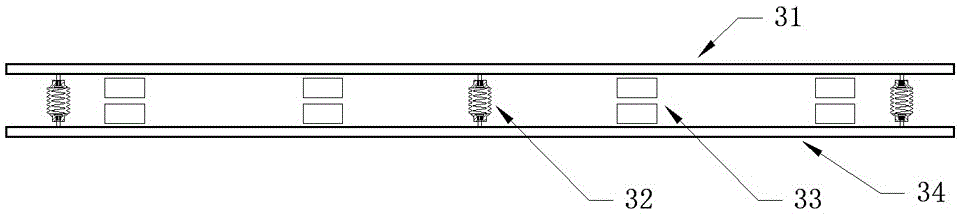

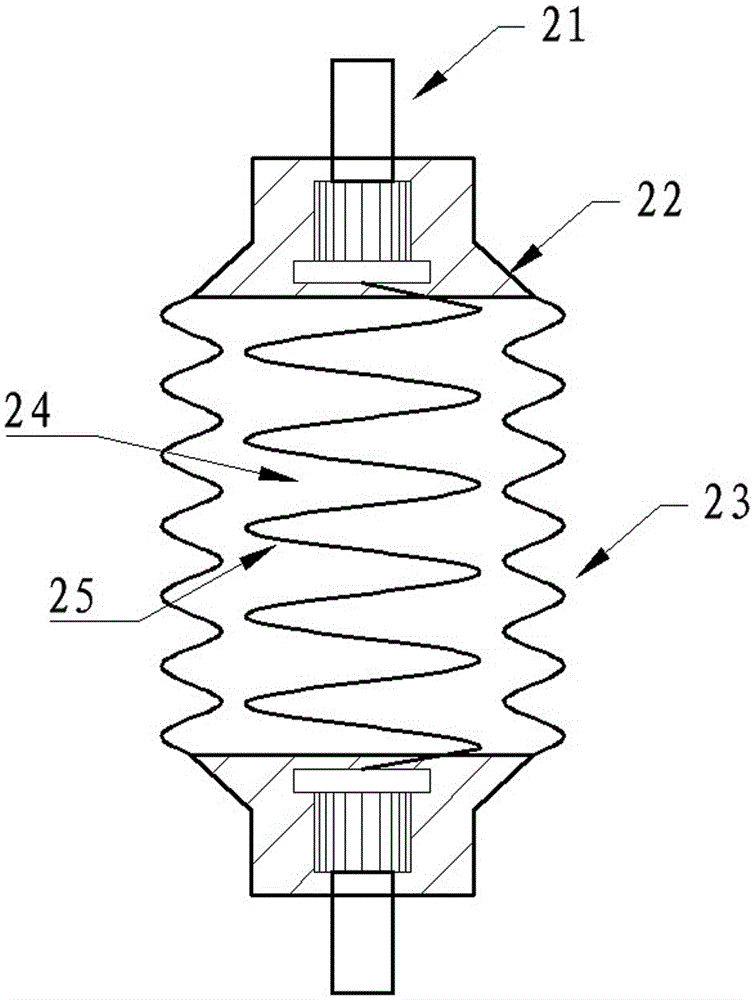

[0022] like figure 1 , figure 2 and image 3 The shown sliding plate brush bristle buffer taper drum type computer monitoring speed walnut pulp removal device, including two tapered drums 3 arranged side by side and rotating in the same direction, the surface of the tapered drum is implanted with moderately soft and hard fibers, and the two tapered drums The distance between them constitutes a V-shaped pulping chamber. The small end of the tapered drum rotates at the lowest linear speed, and the higher the linear speed is toward the larger end. Under the action of the frictional force of the two-tapered drum, the rotary speed will gradually increase linearly and move toward the big end of the tapered drum. The linear speed will become higher and higher, and the walnut can be completely centrifugally rotated without extrusion and frictional damage, thus realizi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com