Experimental apparatus and method for simulating laying of propping agent and backflow of fracturing fluid

An experimental device and proppant technology, applied in teaching models, educational appliances, instruments, etc., can solve problems such as lack of experimental devices for proppant placement and fracturing fluid flowback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

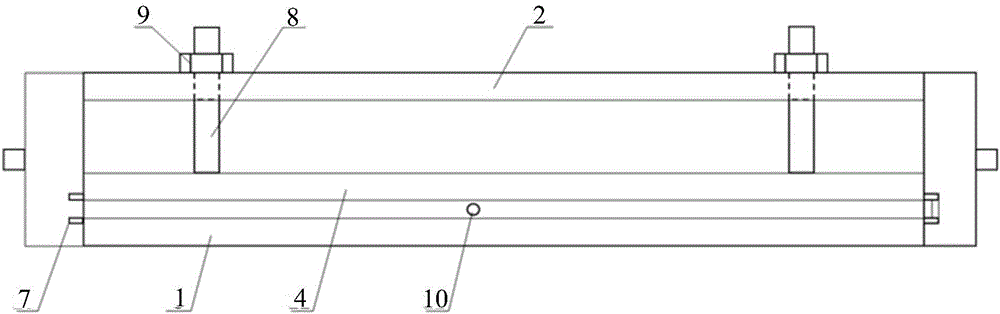

[0058] Embodiment 1 of the present invention provides an experimental device for simulating proppant laying and fracturing fluid flowback. figure 1 It is a schematic structural diagram of an experimental device for simulating proppant laying and fracturing fluid flowback provided in Embodiment 1 of the present invention. figure 2 for figure 1 The top view of the middle box and the water chamber.

[0059] Such as figure 1 and figure 2 As shown, the experimental device for simulating proppant laying and fracturing fluid flowback in this embodiment may include: a first plate 1, a second plate 2, and a frame 3;

[0060] The first flat plate 1 and the second flat plate 2 are arranged in parallel, and the first flat plate 1, the second flat plate 2 and the frame 3 form a sealed box;

[0061] Both the first flat plate 1 and the second flat plate 2 are transparent, and are used for the user to observe the situation inside the box;

[0062] A transparent built-in flat plate 4 is...

Embodiment 2

[0090] Embodiment 2 of the present invention provides an experimental device for simulating proppant laying and fracturing fluid flowback. In this embodiment, on the basis of the device provided in Embodiment 1, a liquid storage tank 14 for supplying fracturing fluid during the flowback experiment is added.

[0091] image 3 It is a schematic structural diagram of an experimental device for simulating proppant laying and fracturing fluid flowback provided in Example 2 of the present invention. Figure 4 for image 3 The top view of the middle box and the water chamber.

[0092] In the device provided in this embodiment, the structures and connections of the first flat plate 1, the second flat plate 2, the frame 3, the built-in flat plate 4, the first water holding chamber 5, and the second water holding chamber 6 are the same as those in the embodiment. One is similar and will not be repeated here. On this basis, a fluid storage tank 14 for containing fracturing fluid is a...

Embodiment 3

[0100] Embodiment 3 of the present invention provides an experimental method for simulating proppant laying and fracturing fluid flowback. Figure 5 It is a flow chart of the experimental method for simulating proppant laying and fracturing fluid flowback provided in Embodiment 3 of the present invention. Such as Figure 5 As shown, the method in this embodiment may include:

[0101] Step 301, adjusting the distance between the first plate and the built-in plate according to the field crack parameters.

[0102] Step 302, closing the connecting seam between the second water storage chamber and the cavity, and connecting the first water storage chamber to the sand mixer through a pump.

[0103] Step 303 : Pump the mixture of proppant and fracturing fluid in the sand mixer into the cavity through the first water chamber according to the construction displacement on site.

[0104] Step 304: After the proppant is accumulated and filled in the cavity to form a sand embankment, ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com