Transmission gear shifting control method suitable for gear failure

A control method and a technology of a transmission, which are applied in transmission control, components with teeth, belts/chains/gears, etc., can solve problems such as engine driver discomfort, speeding engines, and vehicle economy reduction, and achieve improved The effect of economy and power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

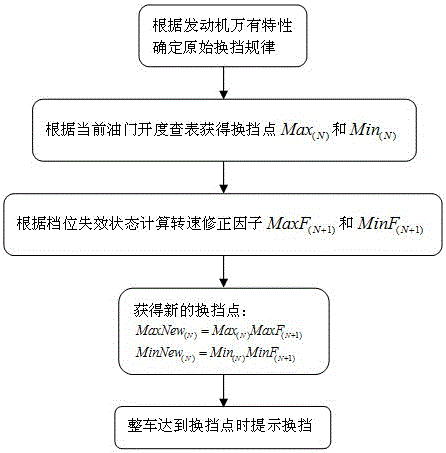

[0024] like figure 1 As shown, a transmission shift control method adapting to gear failure, including the following steps:

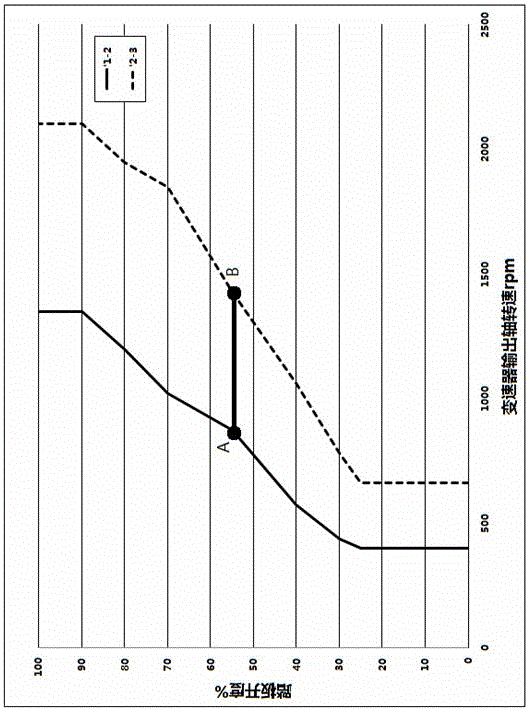

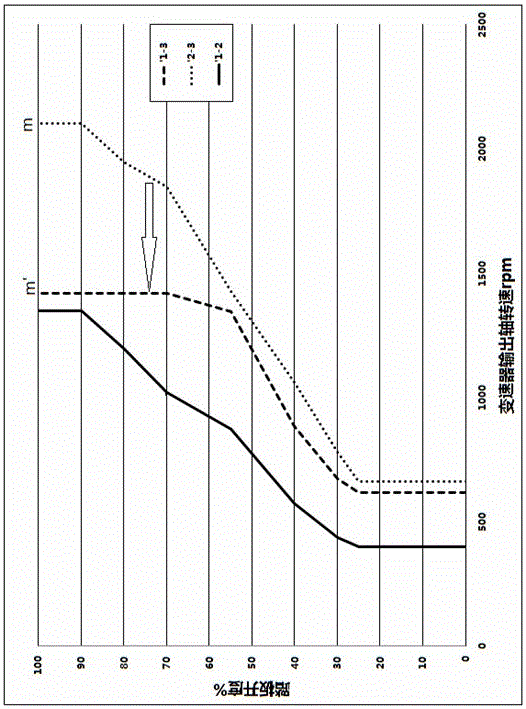

[0025] Firstly, according to the universal characteristic curve of the engine and the speed ratio of the forward gear, the shift schedule of the whole vehicle under different throttle openings is calculated. The shift schedule is an array of [2*(M-1)×11]. The abscissa is the throttle opening 0%, 10%, 20%,..., 90%, 100%, and the ordinate is the shift point 1→ 2, ..., (M-1)→M, M→(M-1),...,2→1, the output data is the output shaft speed corresponding to each shift point at different throttle openings. Define the shift type of each shift point: upshift is 1→2, ..., (M-1) →M; downshift is M→(M-1),...,2→1, where (M-1) → M means (M-1) gear up M gear.

[0026] When the whole vehicle is running, look up the shift schedule ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com