Quick-attach-detach axial expansion compensation structure based on diaphragm coupling

A diaphragm coupling and axial telescopic technology, which is applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of not having the axial telescopic compensation function and cannot be widely used, and achieve extended use Function and application range, improving working accuracy and service life, and improving working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

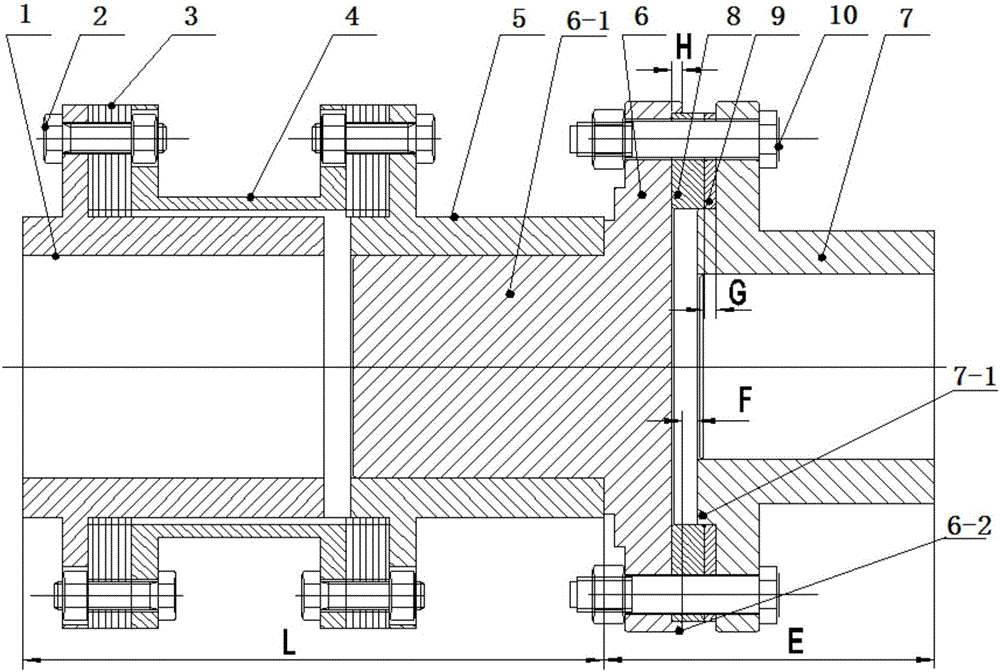

[0018] Such as figure 1 As shown, a quick loading and unloading axial telescopic compensation structure based on the diaphragm coupling, including the diaphragm coupling, the diaphragm coupling is a double diaphragm coupling, including the active end of the diaphragm coupling Flange 1, diaphragm fixing bolt 2, diaphragm 3, diaphragm connection sleeve 4 and diaphragm coupling driven end flange 5,

[0019] The fast loading and unloading axial telescopic compensation structure based on the diaphragm coupling also includes a transition flange 6 and a working machine flange 7 arranged in sequence along the axis of the diaphragm coupling, and the transition flange 6 There is a connecting column 6-1 fixedly connected to the flange 5 hole of the driven end of the diaphragm coupling, and a compensation ring I8 and a compensation ring are sequentially arranged between the transition flange 6 and the working machine flange 7 II9, and the compensation ring I8 and the compensation ring II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com