Lifting type floating feeding device

A lifting type, lifting drive mechanism technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the positioner cannot realize the automatic clamping of the workpiece, the positioning accuracy of the clamping is poor, and the labor intensity is high And other problems, to achieve the effect of improving the working accuracy and service life, stable and reliable work, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

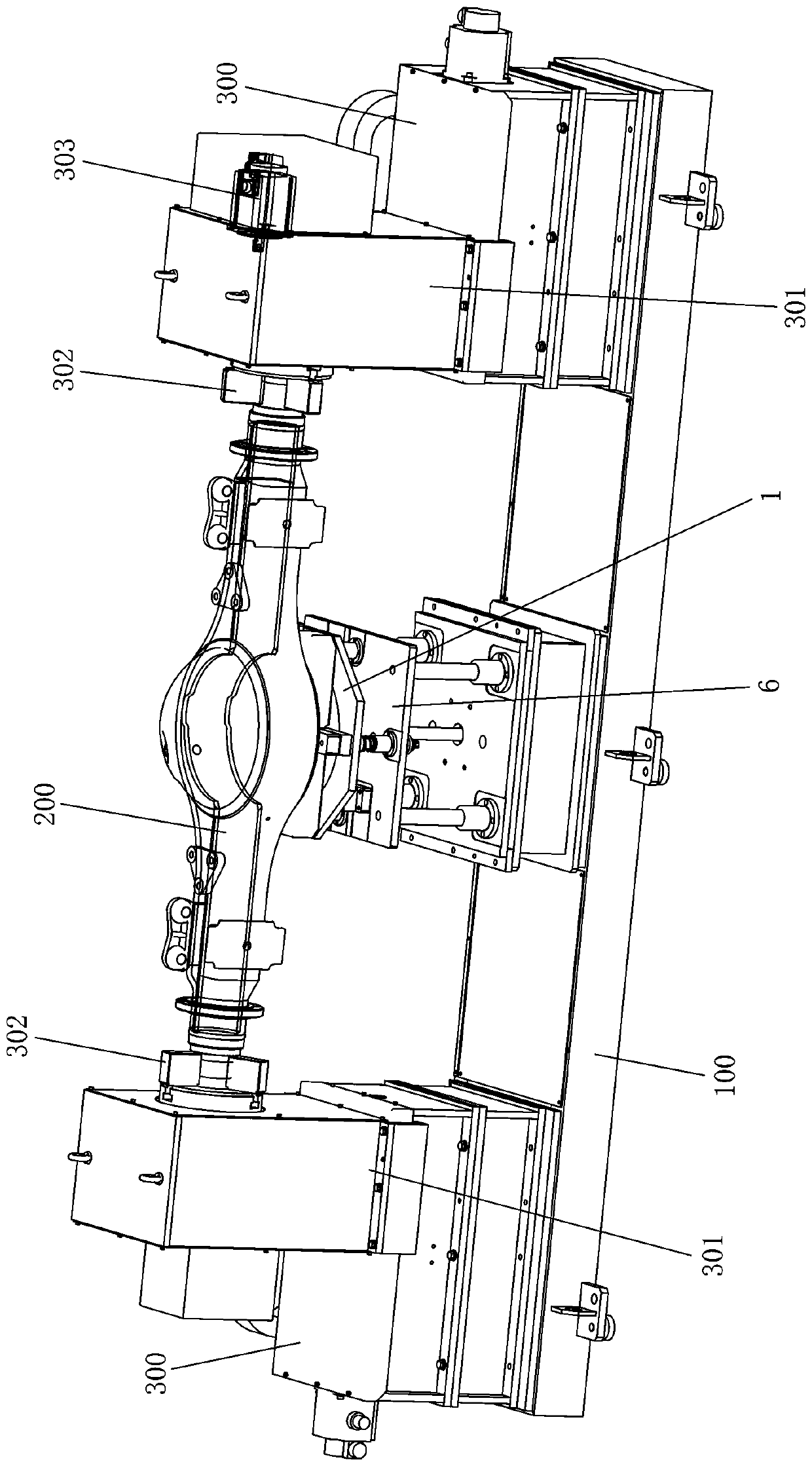

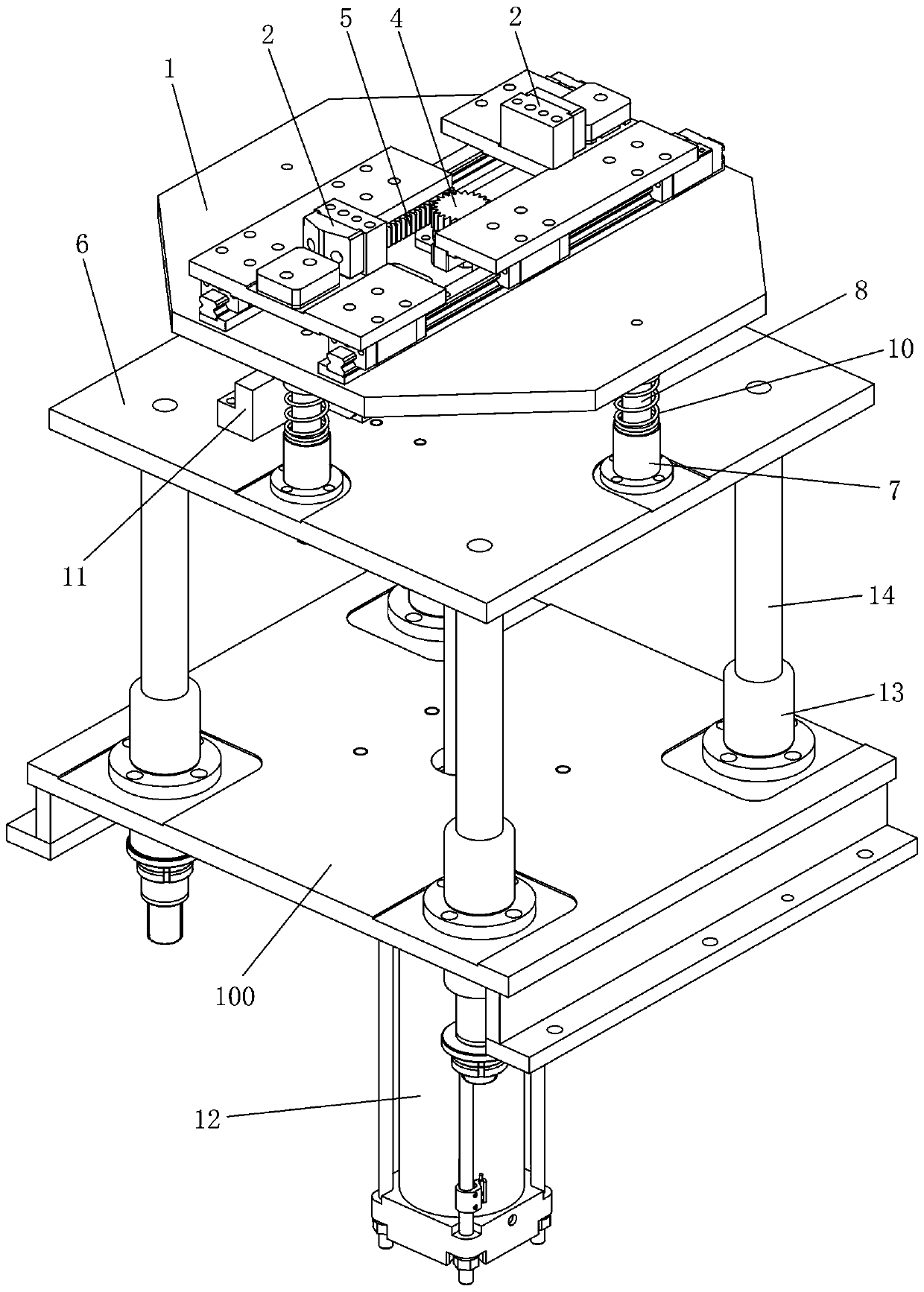

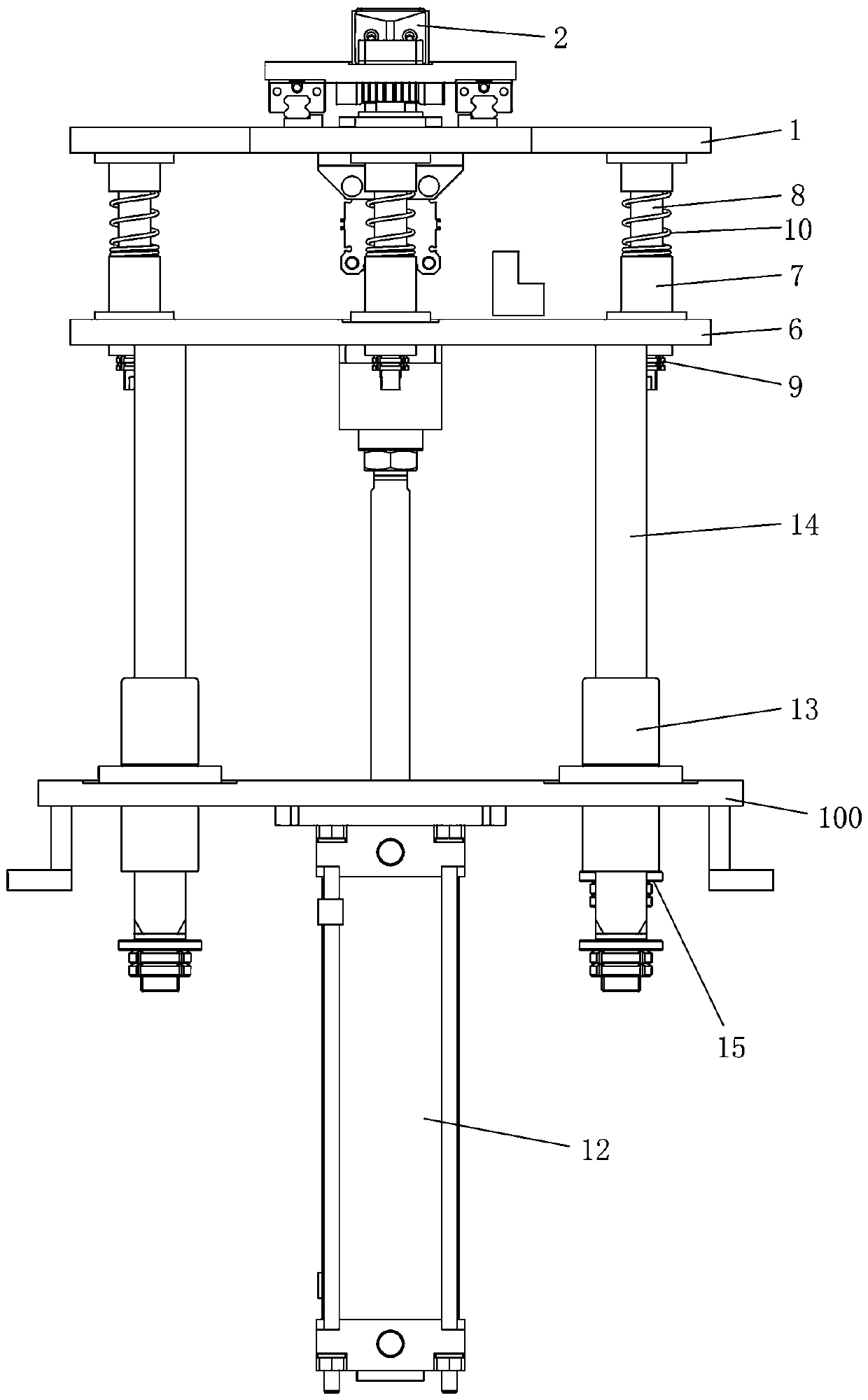

[0019] like Figure 2 to Figure 4 As shown, the lift-type floating feeding device of this embodiment includes a frame 100, a holding base 1 and a fixing assembly arranged on the holding base 1 for fixing the workpiece 200, and the holding base 1 is installed on the machine through the lifting assembly. On the frame 100, the lifting assembly includes the lifting seat 6 which is slid on the frame 100 in the vertical direction and the lifting drive mechanism for driving the lifting seat 6 to move up and down on the mounting frame 100, and the supporting seat 1 is installed on the frame by a floating mechanism. Lifting seat 6 and can elastically float up and down on lifting seat 6. The lift-type floating feeding device uses a fixed component to fix the workpiece 200, and the lifting component drives the supporting seat 1 to move up and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com