A flooding method of injecting strong high-pressure air and enriched oxygen into deep ancient buried hill reservoirs

A technology of high-pressure air and oil displacement method, which is applied in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc. Oxidative cracking speed is slow and other problems, to achieve the effect of improving oil recovery rate and recovery rate, avoiding excessive nitrogen content, and rapid oxidative cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] An oil displacement method for injecting strong high-pressure air and enriched oxygen into a deep ancient buried hill reservoir, comprising the following steps:

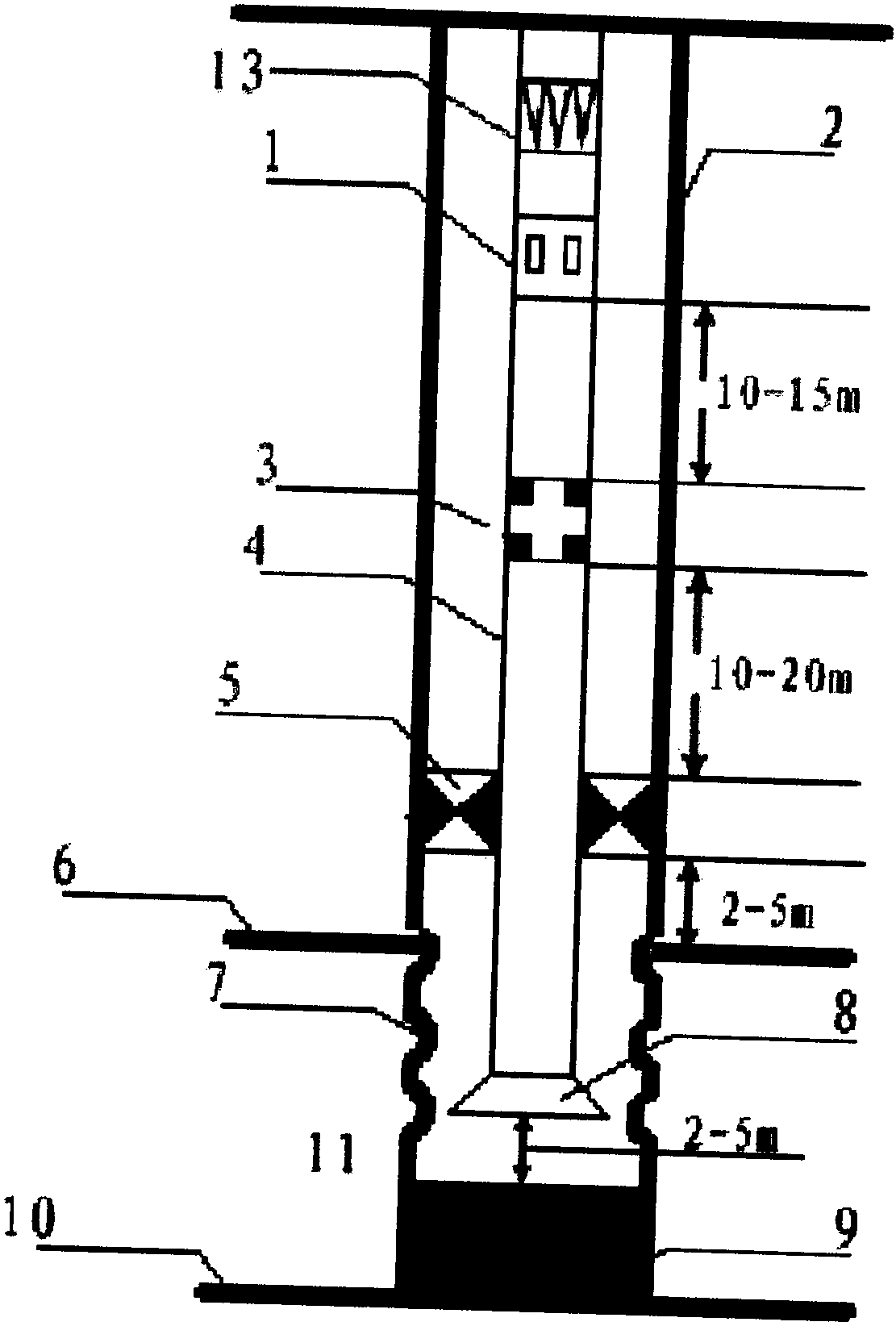

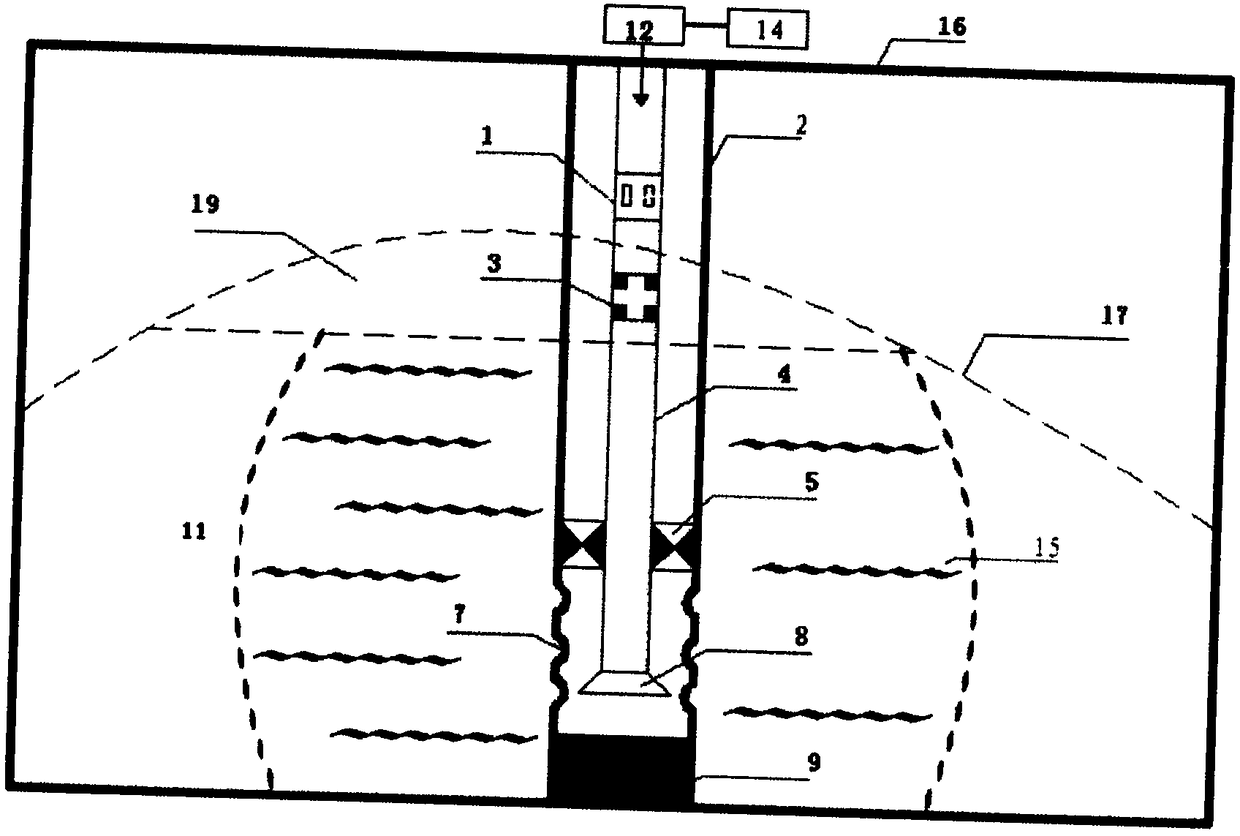

[0041] Step 1. First perform high-pressure gas injection well completion on the gas injection well, such as figure 1 As shown in the figure, the sequence of components running into the well is the bell mouth (8), packer (5), safety valve (3), sliding sleeve (1), and compensator (13), which are lowered together with the tubing (4). Enter the bottom of the well, run the bell mouth to 4 meters above the artificial well bottom (9) and 7 meters above the overburden (10), and adjust the position of the packer to above the overburden (6) in the middle and lower part of the perforation section (7) At 3 meters, the safety valve is adjusted to 18 meters above the packer, and the sliding sleeve is adjusted to 10 meters above the safety valve. together to form a closed space.

[0042] Step 2. After well completion, inject...

Embodiment 2

[0049] An oil displacement method for injecting strong high-pressure air and enriched oxygen into a deep ancient buried hill reservoir, comprising the following steps:

[0050] Step 1. First perform high-pressure gas injection well completion on the gas injection well, such as figure 1 As shown in the figure, the sequence of components running into the well is the bell mouth (8), packer (5), safety valve (3), sliding sleeve (1), and compensator (13), which are lowered together with the tubing (4). Enter the bottom of the well, run the bell mouth to 5 meters above the artificial well bottom (9) and 10 meters above the overburden (10), and adjust the position of the packer to above the overburden (6) in the middle and lower part of the perforation section (7) At 5 meters, the safety valve is adjusted to 15 meters above the packer, and the sliding sleeve is adjusted to 10 meters above the safety valve. together to form a closed space.

[0051] Step 2. Inject 0.1PV of a mixture ...

Embodiment 3

[0058] An oil displacement method for injecting strong high-pressure air and enriched oxygen into a deep ancient buried hill reservoir, comprising the following steps:

[0059] Step 1. First perform high-pressure gas injection well completion on the gas injection well, such as figure 1 As shown in the figure, the sequence of components running into the well is the bell mouth (8), packer (5), safety valve (3), sliding sleeve (1), and compensator (13), which are lowered together with the tubing (4). Enter the bottom of the well, run the bell mouth to 3 meters above the artificial well bottom (9) and 5 meters above the overburden (10), and adjust the position of the packer to above the overburden (6) in the middle and lower part of the perforation section (7) At 4 meters, the safety valve is adjusted to 15 meters above the packer, and the sliding sleeve is adjusted to 10 meters above the safety valve. together to form a closed space.

[0060] Step 2. Inject the mixture of 0.15P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com