Tube structure roof panel construction method and hanger formwork system

A construction method and roof panel technology, applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of high risk factor, difficult roof panel construction, and heavy workload, so as to reduce the risk factor , expand the scope of use and use time, reduce the effect of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

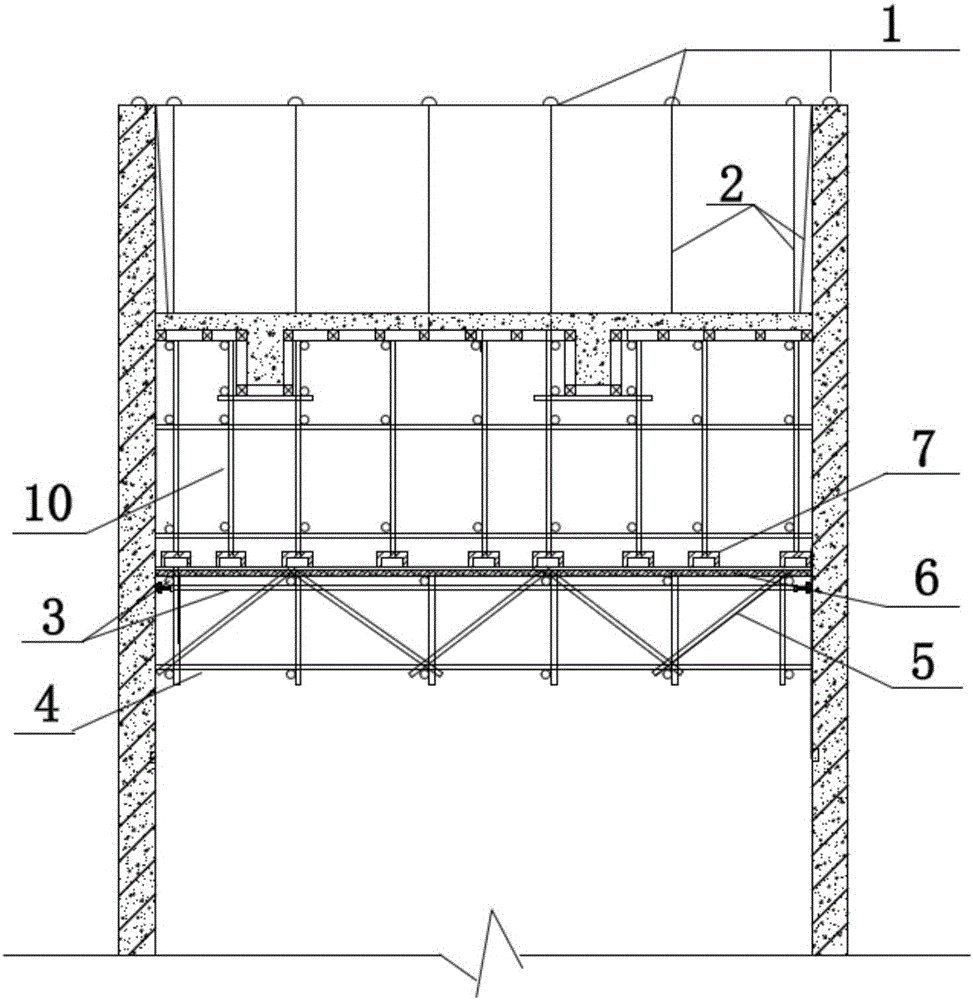

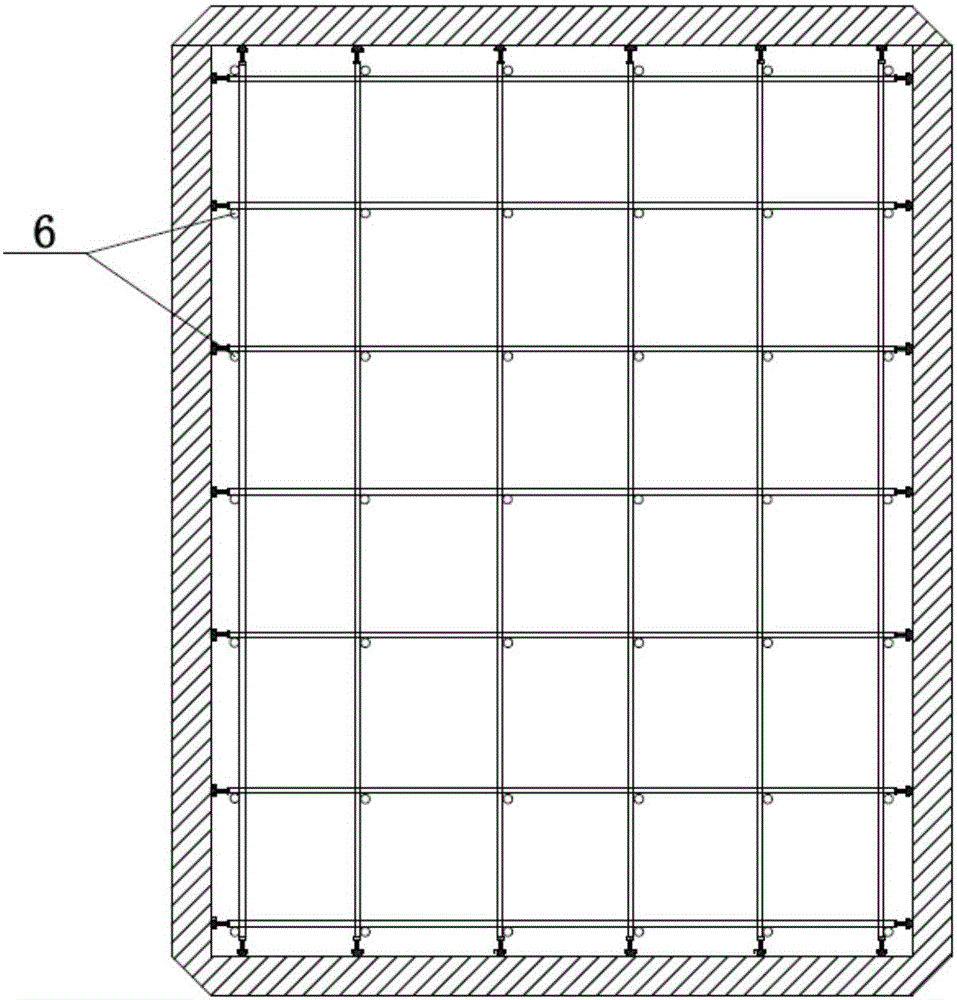

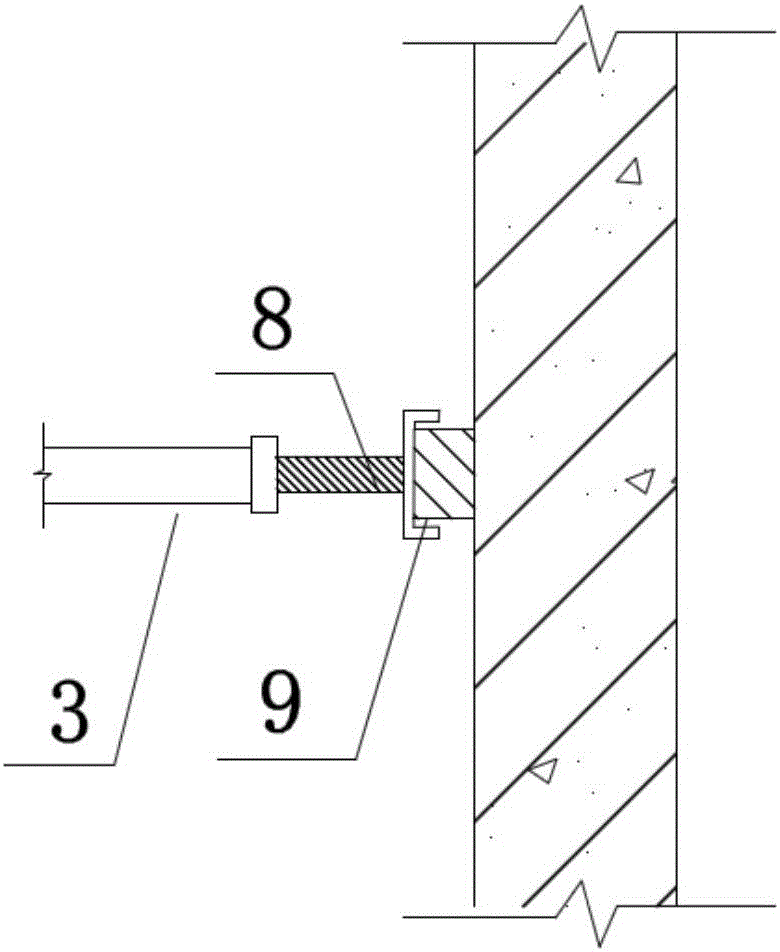

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0022] like Figure 1-3 As shown, the roof panel construction method of the cylinder structure of the present invention comprises the following steps,

[0023] 1) Use the sliding form construction method to construct the cylinder structure and set the embedded ring 1 at the top of the cylinder wall,

[0024] 2) After the construction of the sliding form of the cylinder wall is completed, the inner frame of the sliding form and the outer frame of the sliding form are separated and the inner frame of the sliding form is lowered below the elevation of the roof panel;

[0025] 4) Use the steel wire rope 2 to fix the inner frame of the synovial film with the embedded ring tie, and then f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com