A Simple Preparation Method of Antimony Phosphate with Mixed Morphology

A morphological structure, antimony phosphate technology, applied in the field of photocatalytic materials, can solve the problem of less antimony phosphate in pure phase, and achieve the effects of simple and easy operation, pure product and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] In a water bath at 60°C, add 1.965g of diethylenetriaminepentaacetic acid and 1.141g of antimony trichloride into 65mL of deionized water and stir for 1h; add 0.575g of antimony trichloride and stir for 0.5h to form a precursor mixture. Pour the precursor mixed solution into a 50mL polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, conduct a hydrothermal reaction at a constant temperature of 160°C for 10h, and then centrifuge, wash and dry.

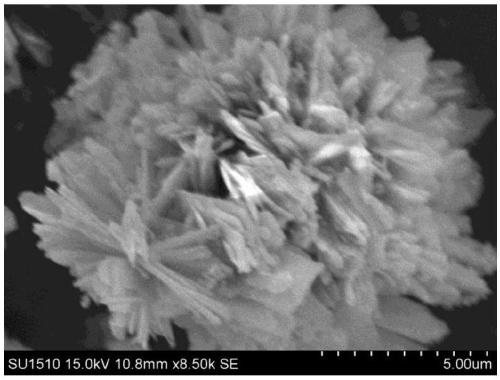

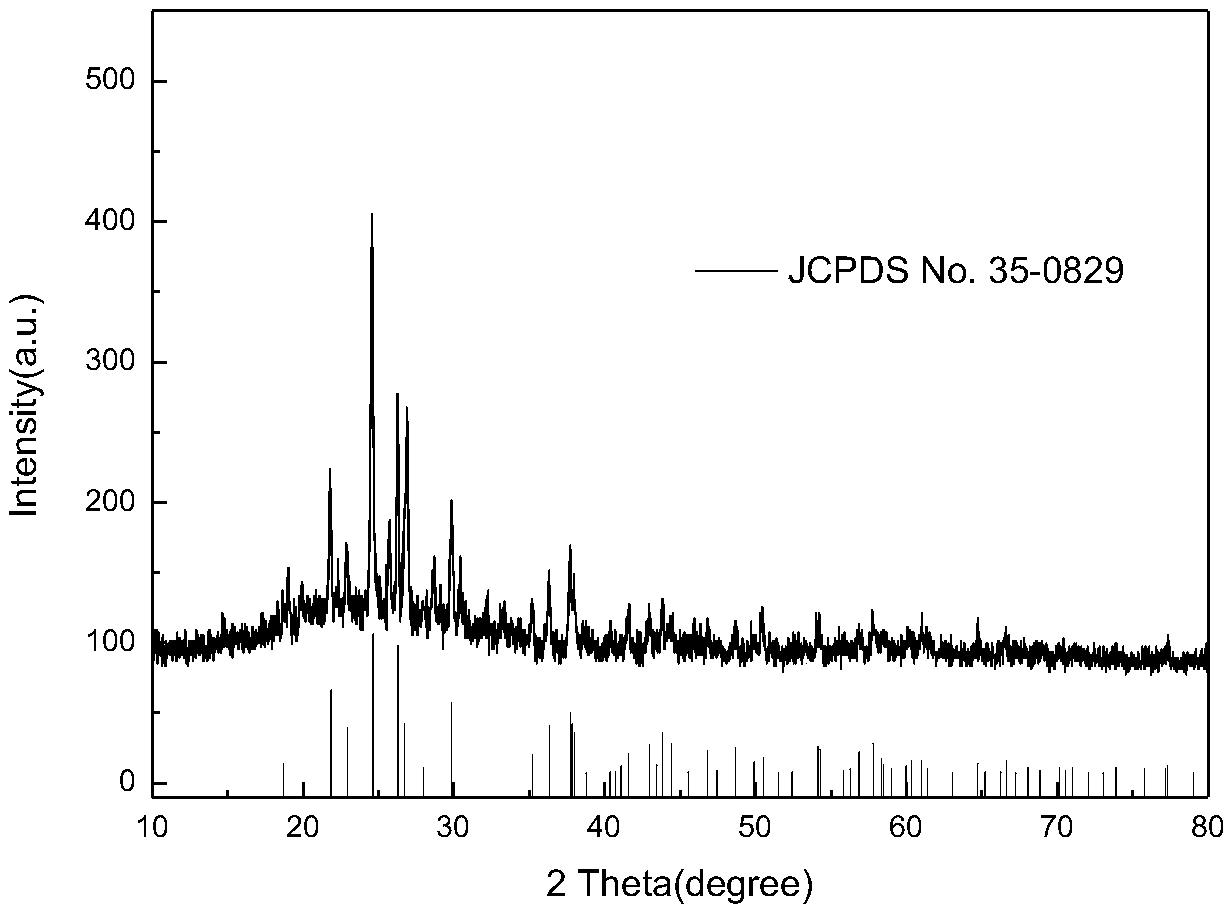

[0025] The prepared antimony phosphate was observed by electron microscope and determined by X-ray diffraction.

[0026] From figure 1 It can be seen from the figure that the antimony phosphate nanorods prepared by the present invention have a quadrangular columnar structure, the length of the rods is 35-45 μm, and the side length of the cross-section is 0.15-0.9 μm.

[0027] From figure 2 It can be seen from the figure that the diameter of the microspheres assembled with antimony phosphate nanosheets i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com