Ring Crane for Blast Furnace Refractory Brick Construction

An annular crane and refractory brick technology, which is applied in the direction of load block, load hanging element, portable lifting device, etc., can solve the problem of unavailability of lifting machinery, and achieve the effect of easy local material acquisition, simple operation and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiments, but the scope of protection of the present invention is not limited to the content of the following examples.

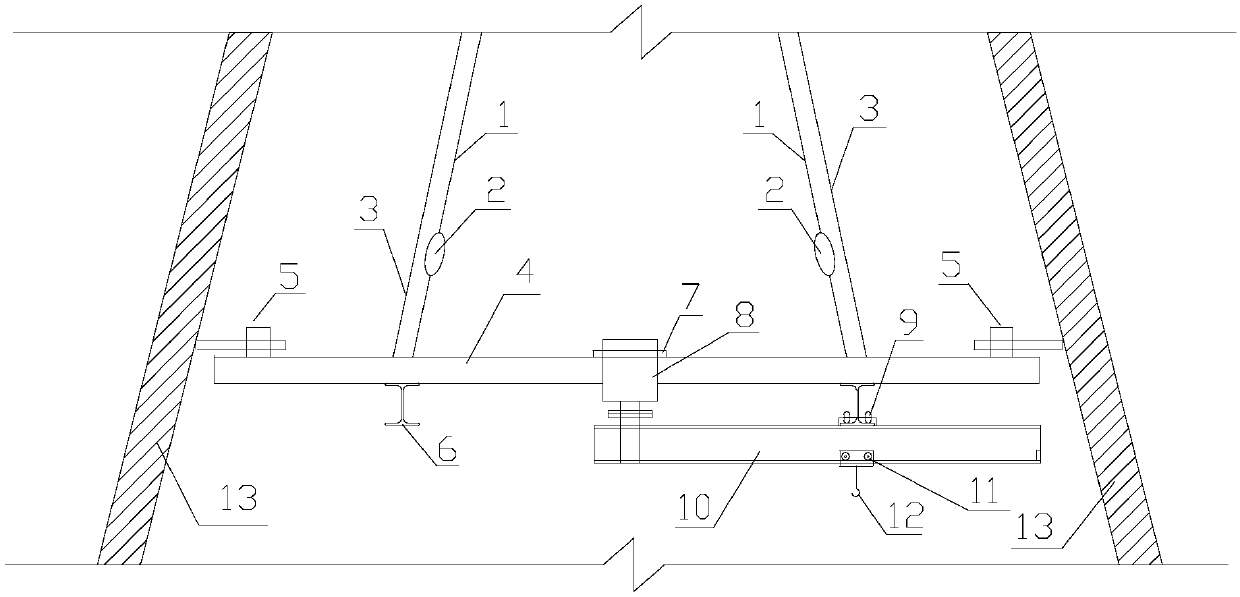

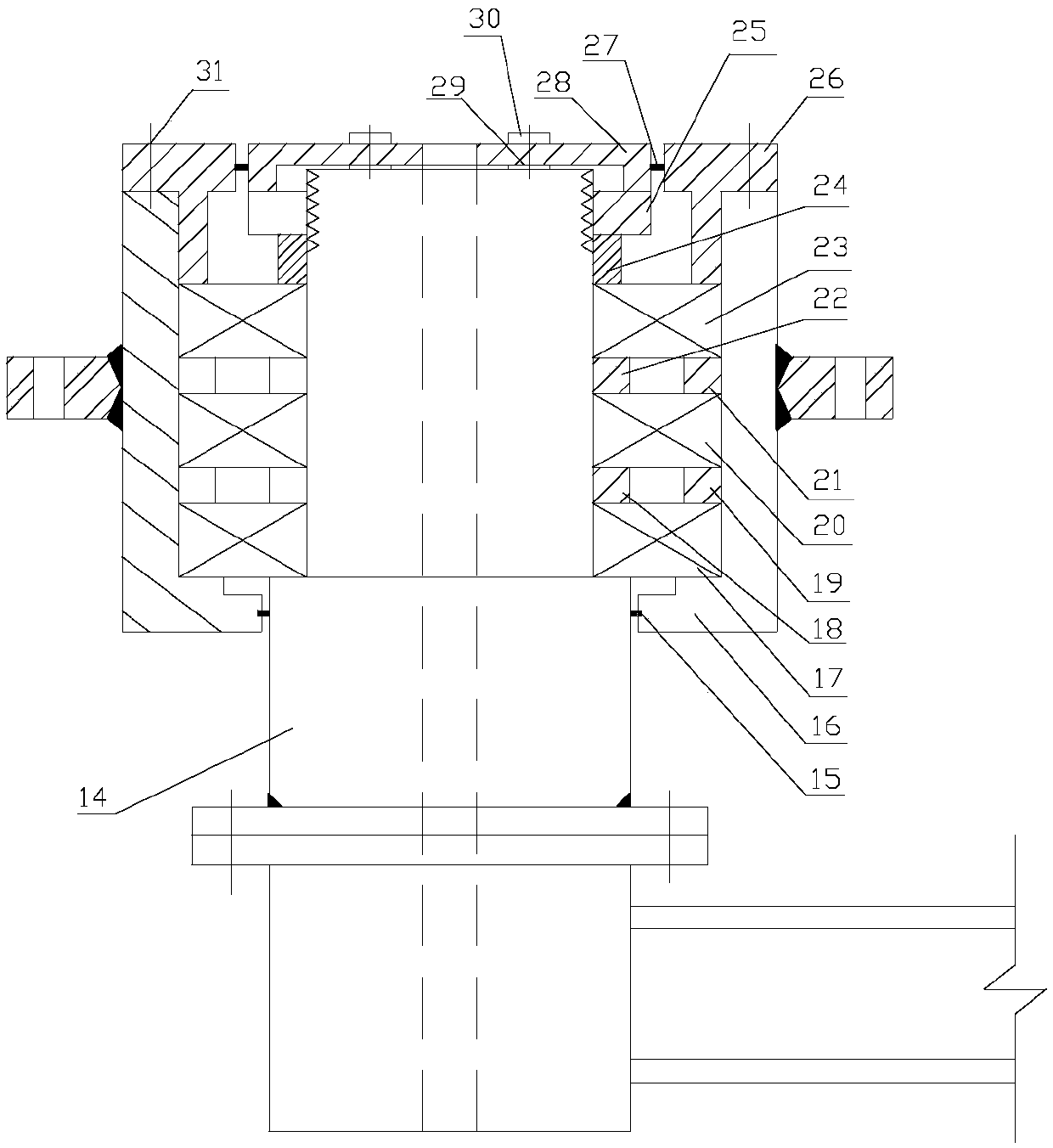

[0023] Such as Figure 1-2 As shown, the circular crane used for the construction of blast furnace refractory bricks, the self-elevating system lifts the wire rope 1, the lever block 2, the self-elevating system safety wire rope 3, the hanging pan 4, the fixing device 5, the rotating mechanism 8, the circular track 6, and the rotating trolley 9. It is composed of a boom 10, a horizontal traveling trolley 11 and a lifting device 12.

[0024] The suspension pan 4 is used as a circular crane to lift and fix the body of the circular track 6, the rotating mechanism 8, and the boom 10, and is fixed in the vertical direction by the lifting wire rope 1 of the jacking system and the safety wire rope 3 of the jacking system. The number of sets of steel wire rope 1 and safety...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com