Crease and knitted composite fabric with good tear resistance

A technology of knitted fabrics and composite fabrics, applied in the field of textile fabrics and fabrics, can solve the problems of inconvenience of movement, wearing abscesses, increased fabric thickness, etc., and achieve the effect of light and thin quality, good tear strength and full of fashion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

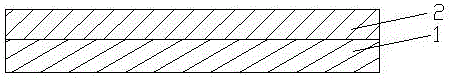

[0009] see figure 1 , the present invention relates to a composite fabric of pleats and knitting with better tear strength, comprising a knitted fabric body 1, fixing the pleated fabric 2 with threads on the surface of the knitted fabric body 1, and when the clothes made of the pleated and knitted composite fabric, The pleated fabric 2 is on the outside, and the knitted fabric body 1 is on the inside.

[0010] The back of the knitted fabric body is provided with a lining fabric layer, and the lining fabric layer is a composite fabric, which includes: a first weaving layer and a first film layer, and the first weaving layer has a first Surface, a second surface and a plurality of pores, the pores are distributed in the first fabric layer and communicated with the first surface and the second surface; the first film layer has a third surface and a fourth surface , the fourth surface of the first film layer leans against the first surface of the first fabric layer and partially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com