Forming machine for strip-type materials

A molding machine and material technology, applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems of labor and cost, low manufacturing efficiency, downstream process impact, etc., to reduce labor and cost, improve molding The effect of improving quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

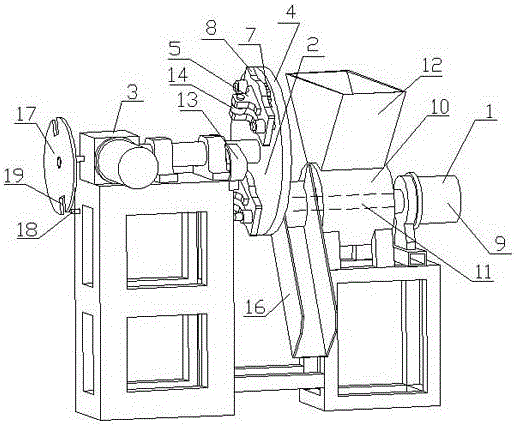

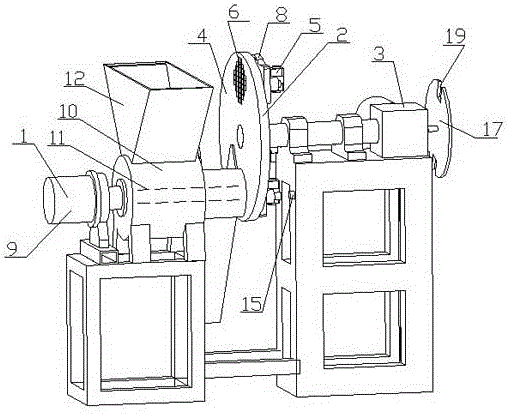

[0036] As shown in the figure, a strip-shaped material molding machine includes a screw feeding mechanism 1, an extrusion molding mechanism 2 and a rotary power device 3, and the extrusion molding mechanism 2 includes a working disc 4 and a punch device 5;

[0037] Described work disk 4 is provided with more than one group of die hole districts 6, and described die hole district 6 is provided with more than one die hole, and described die hole is the through hole that offers along the axis of work disk 4, and mold The shape of the hole is consistent with the shape of the bar material, and the depth of the die hole is equal to or greater than the length of the bar material;

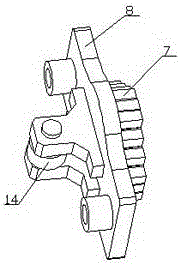

[0038] Described punch device 5 comprises die bar 7 and connector 8, and described die bar 7 is arranged on the number of corresponding die holes and arranged on connector 8, and the shape of die bar 7 is corresponding to die hole shape, and die The length of the rod 7 is consistent with the depth of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com