A master mold, mold, injection molding equipment and method for adjusting cavity depth thereof

A technology of injection molding equipment and master mold, which is applied in the field of injection molding equipment and its cavity depth adjustment, master mold, and mold, which can solve the problems of wasting time and achieve the effect of saving mold trial time and quickly adjusting mold fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

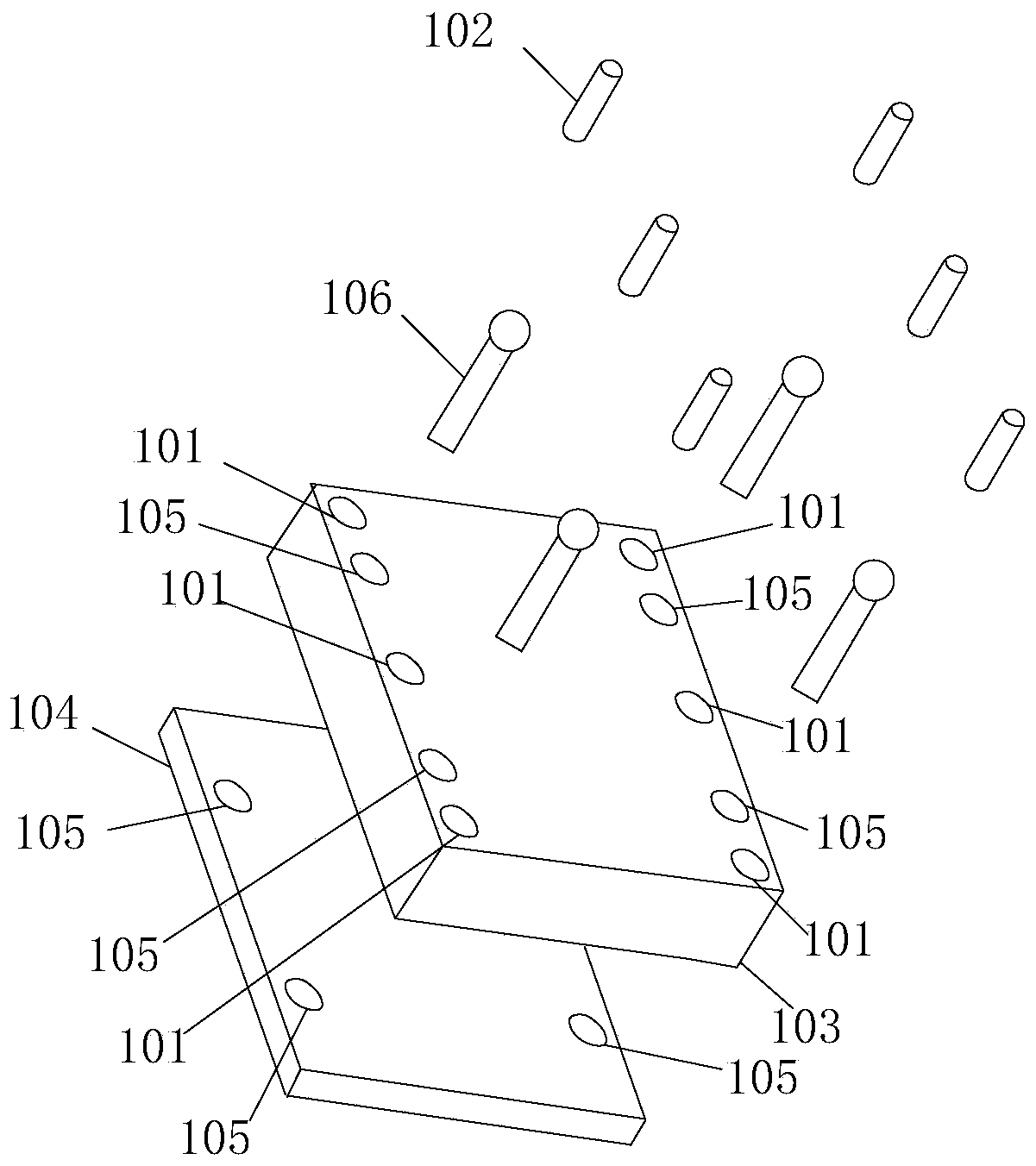

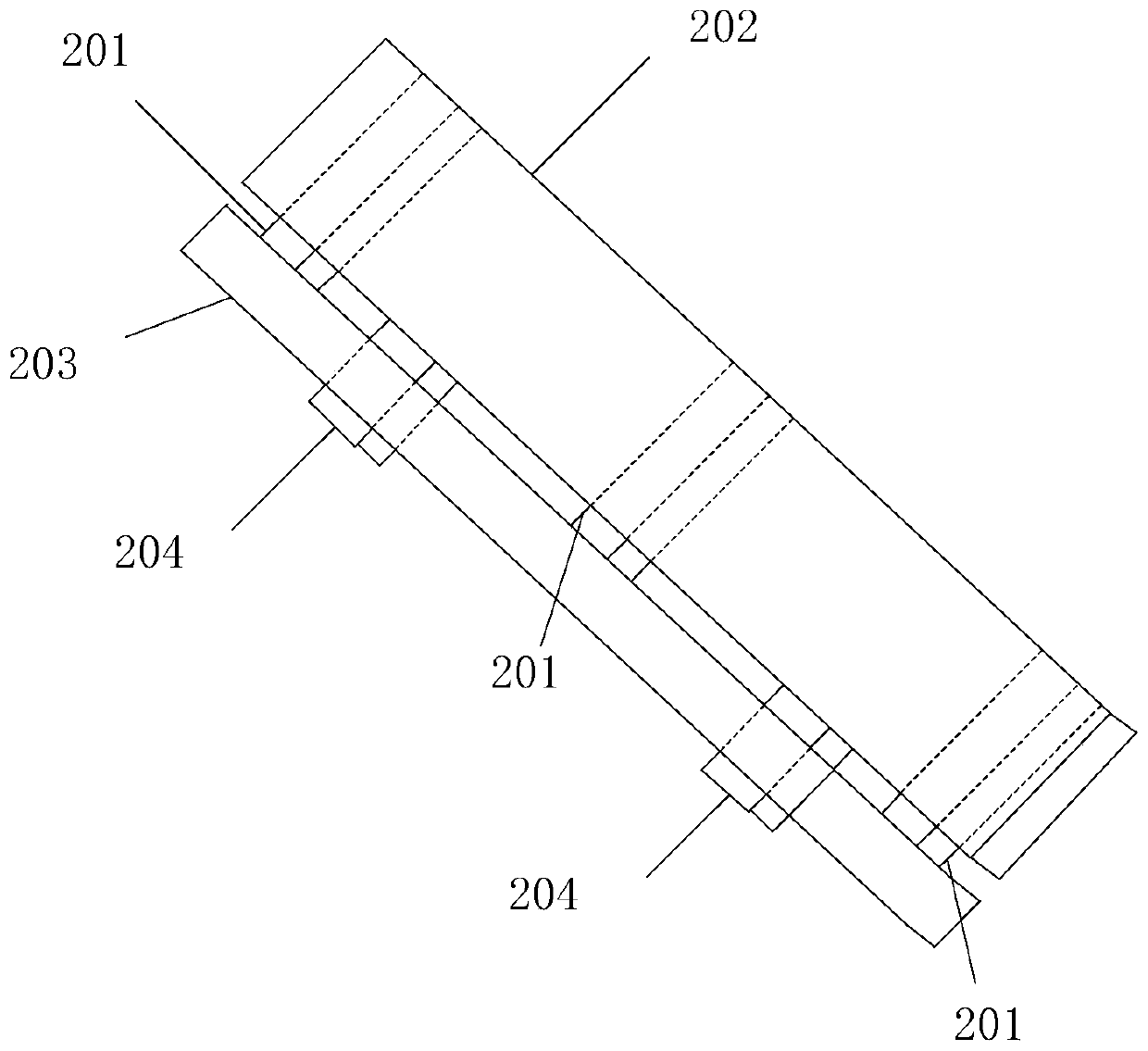

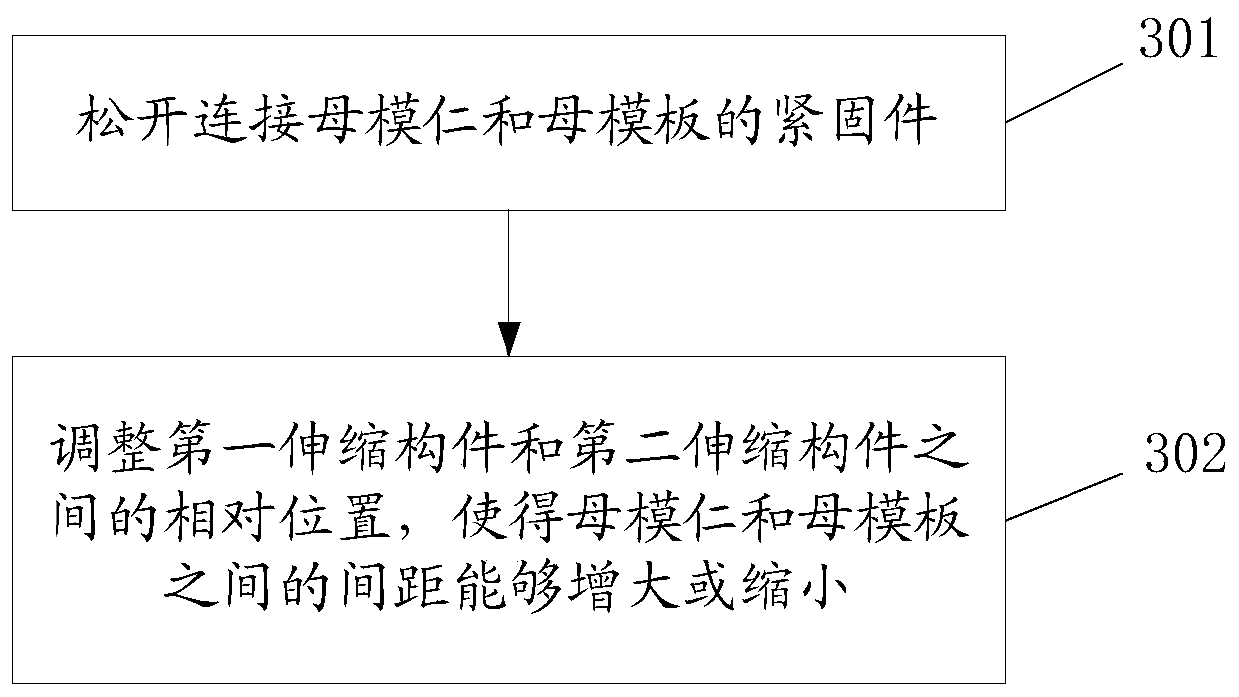

[0024] The present invention firstly provides a master mold, including a master mold core and a master template connected by fasteners; a telescopic adjustment mechanism connected with the master mold core and the master template; the telescopic adjustment mechanism includes a first telescopic member and a second telescopic member. Components; the first telescopic member is connected to the master core and / or the second telescopic member is connected to the master template; the first telescopic member and the second telescopic member can be relatively telescopically moved, so that the master core and the master template can move relatively.

[0025] It can be seen from the above that the master mold provided by the present invention can adjust the relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com