Tool for adjusting wrist clearances of industrial robot

A technology for industrial robots and debugging tooling, applied in the direction of manipulators, manufacturing tools, etc., can solve problems such as trouble, increased wrist gap, and complexity, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

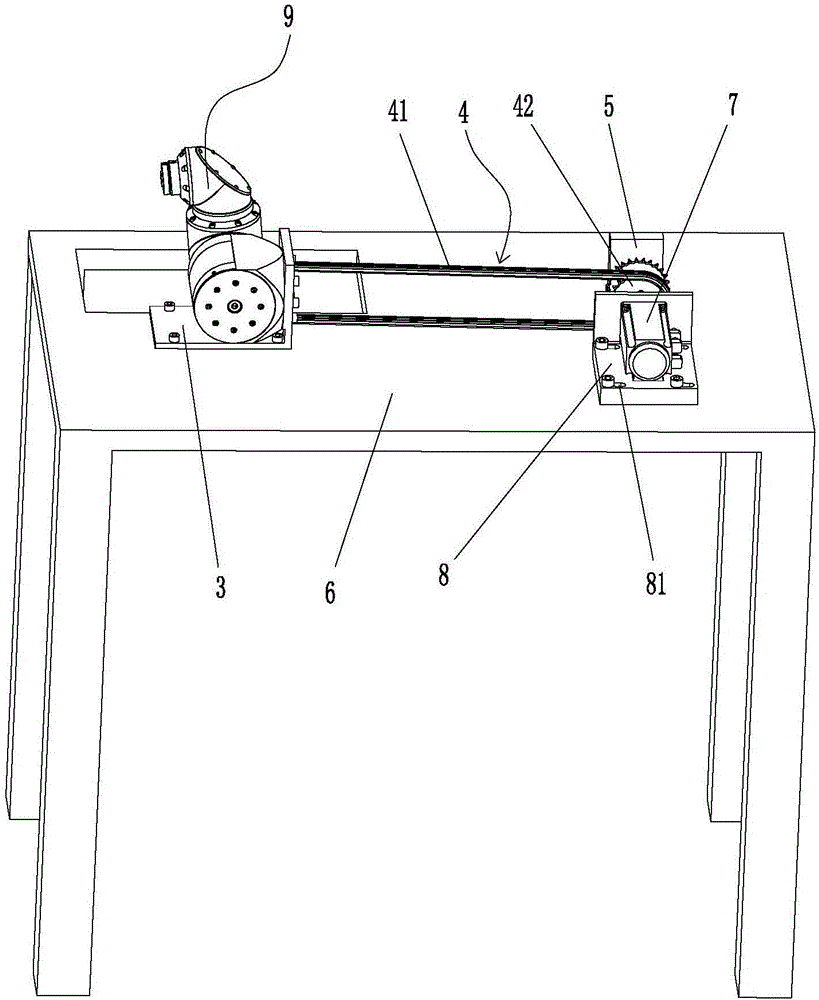

[0014] The following is a further detailed description of the industrial robot wrist gap debugging tool of the present invention in conjunction with the accompanying drawings and specific embodiments:

[0015] Such as figure 1 As shown, in this specific embodiment, the industrial robot wrist gap debugging tool of the present invention includes a workbench 6, a wrist fixing plate 3, a motor 7, and a drive mechanism 4 for driving the rotation of three axes on the wrist. The drive mechanism 4 and Motor 7 is connected, and wrist fixed plate 3 and motor 7 are all installed on the workbench 6. Described drive mechanism 4 comprises chain 41 and sprocket wheel 42, and sprocket wheel 42 is contained on the motor 7 rotating shafts, and chain 41 right-hand ends engage with sprocket wheel 42, and after chain 41 left-hand ends pass through the through hole that offers on wrist fixing plate 3, respectively Used to mesh with the sprockets on the three axes of the wrist.

[0016] As prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com