Adjustment Method of Individual Value of Numerical Control Wire Turning Locomotive

An adjustment method and single value technology, applied in the field of CNC machine tools, can solve problems such as difficulty in adjusting the single value of the coupling, and achieve the effects of improving the coupling operation rate, saving costs, and having good use effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] In order to make those skilled in the art better understand the technical solution of the present invention, the technical solution of the present invention is clearly and completely described below in conjunction with the preferred embodiments of the present invention. Based on the embodiments in this application, those of ordinary skill in the art Other similar embodiments obtained without creative work shall all fall within the protection scope of the present application.

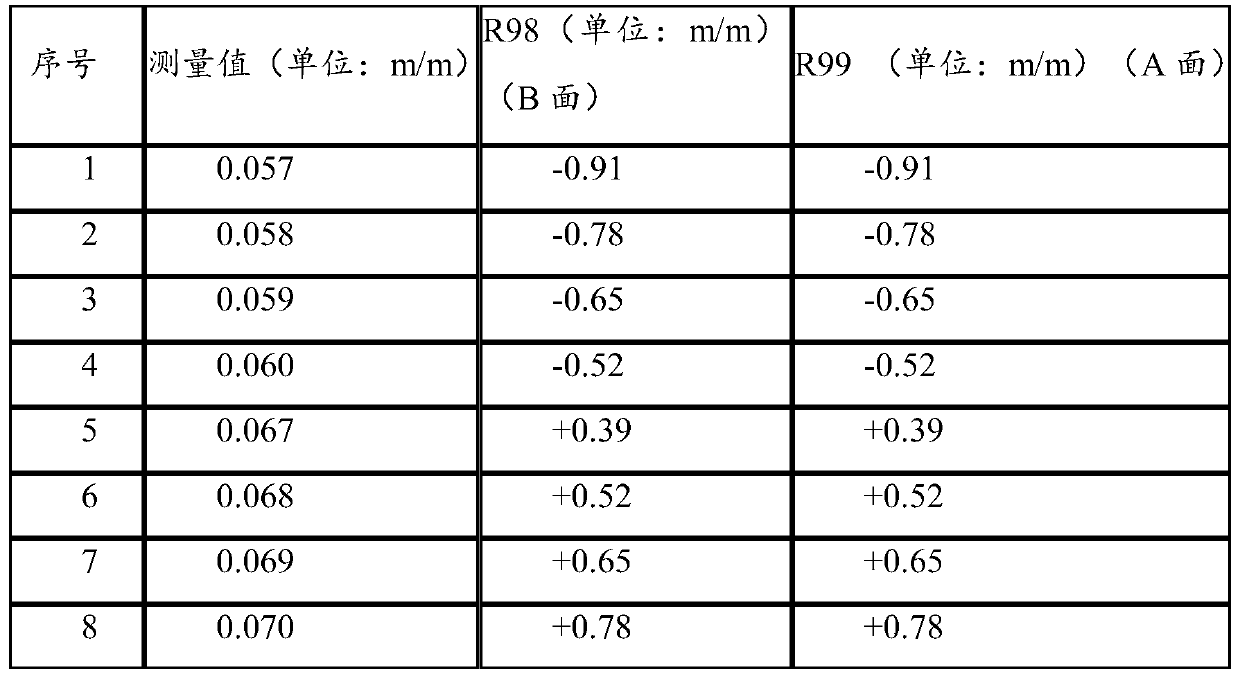

[0079] Colinet C7 and C10 coupling threading machines adopt the simens 840Di system. In the 840Di system, the R parameter can be calculated or set by the controller when the program is running, or the parameter value can be set through the operation panel. There are a total of 300 simens calculation parameters R available for use. Write R parameters in machining programming, and input the changing adjustment values into the CNC memory through instructions. The present invention finally selects t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com