A Sand Adding Molding Method of a Mobile Rain Sand Adder

A rain shower sander, mobile technology, applied in casting molding equipment, casting workshop, manufacturing tools, etc., can solve the problems of high cost, large equipment investment, low efficiency, etc., to reduce equipment cost and simplify equipment structure. , the effect of reducing the number of workstations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

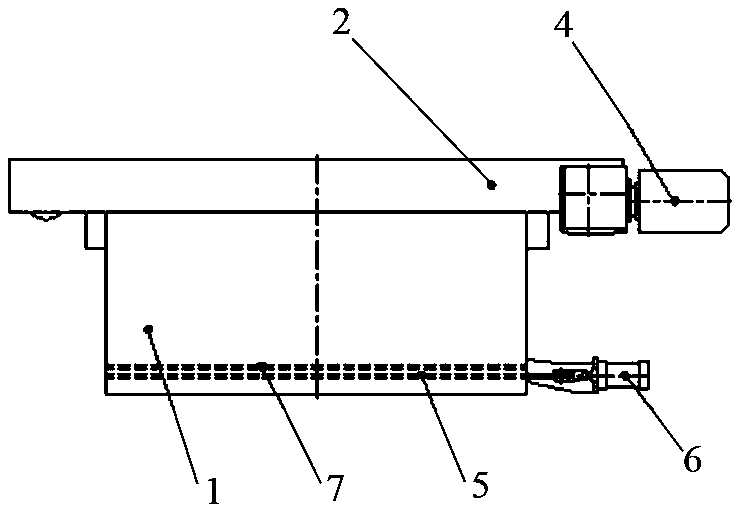

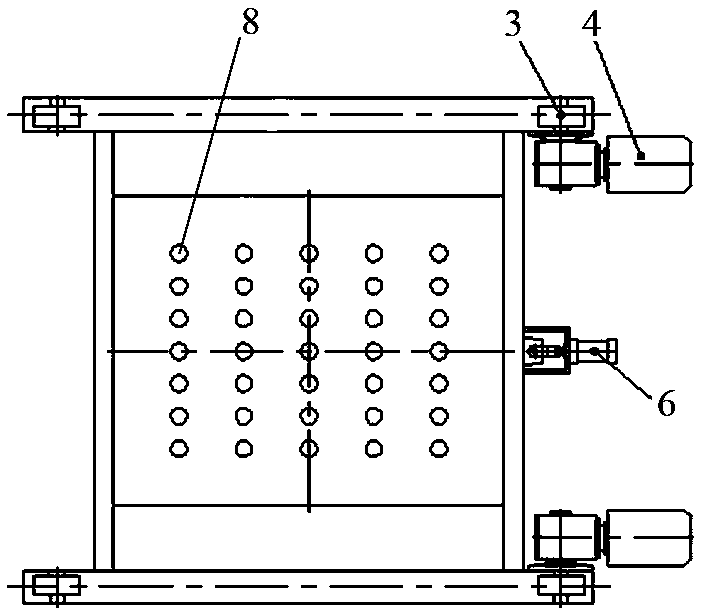

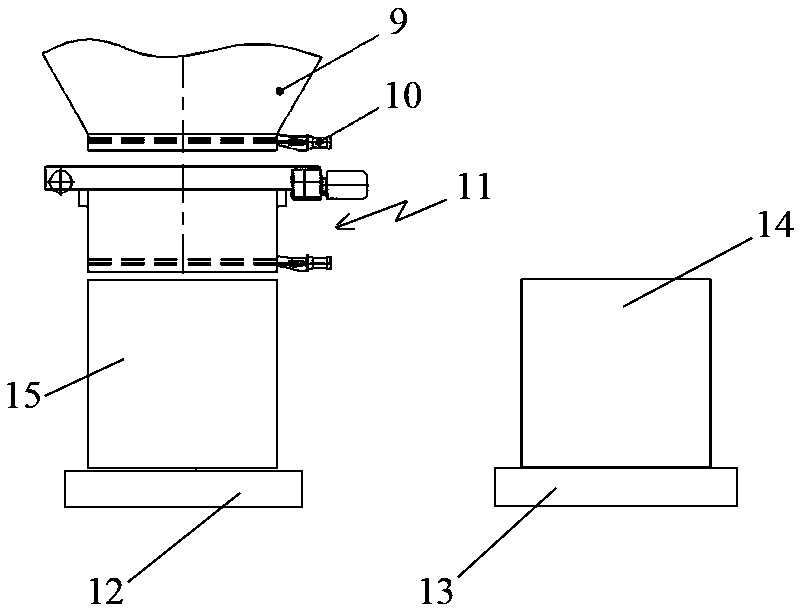

[0024] like figure 1 and figure 2 As shown, the mobile deluge sander of the present invention is mainly composed of a sand storage box 1, a pull-out gate 5, a cylinder 6, and a driving traveling mechanism.

[0025] The sand storage box 1 is a rectangular box body, and its top is open as a sand filling port for adding molding sand in the box. A number of sand leakage holes are provided on the bottom plate 7 of the sand storage box 1 as channels for the molding sand in the box to fall. The pull-out ram 5 is slidably arranged under the bottom plate 7, and its upper surface is in close contact with the lower surface of the bottom plate 7. One end of the pull-out ram 5 is connected with the cylinder 6, and the cylinder 6 is used to drive the pull-out ram. The flashboard 5 performs the reciprocating motion of extending and retracting. A number of sand passage holes 8 are arranged on the pull-out gate 5, and the distribution positions of the sand passage holes should ensure that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com