Ultrasonic mixing vacuum stirring tank for natural ester insulation oil

A vacuum stirring and ultrasonic technology, which is applied to mixers, mixers, and mixer accessories with rotating stirring devices, can solve problems such as the performance degradation of natural ester insulating oil, and achieve the purpose of improving service life, preventing damage and improving stirring efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

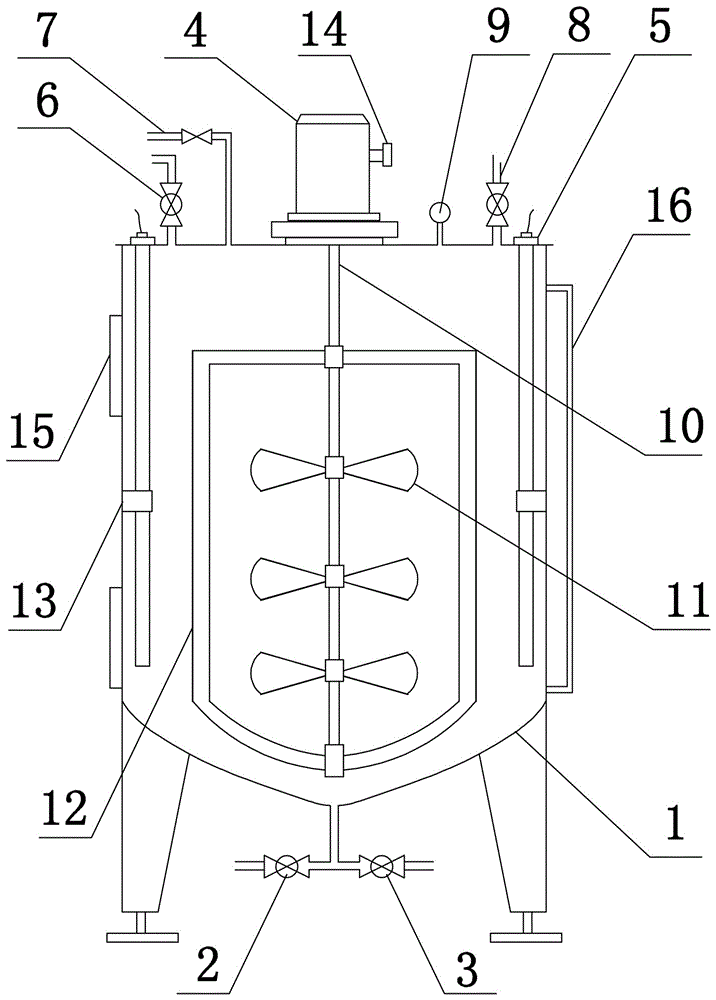

[0027] Such as figure 1 As shown, the present invention includes tank body 1, one-way feed valve 2, one-way discharge valve 3, stirring paddle, frequency conversion motor 4, ultrasonic vibrating rod 5, vacuum pumping valve 6, pressure relief valve 7, additive feeding The valve 8 and the vacuum gauge 9; the one-way feed valve 2 and the one-way discharge valve 3 are sealed and installed at the bottom of the tank body 1; the stirring paddle is located in the tank body 1, including the rotating shaft 10, the inclined blade paddle 11 and the frame paddle 12 , three inclined-blade paddles 11 are fixed in the middle of the rotating shaft 10, the upper frame of the frame-type paddle 12 is located above the uppermost pitched-blade paddle 11, and the lower frame of the frame-type paddle 12 is located below the lowermost pitched-blade paddle 11 The frequency conversion motor 4 is installed above the tank body, and the rotating shaft 10 extends out of the tank body and is sealed and rotat...

Embodiment 2

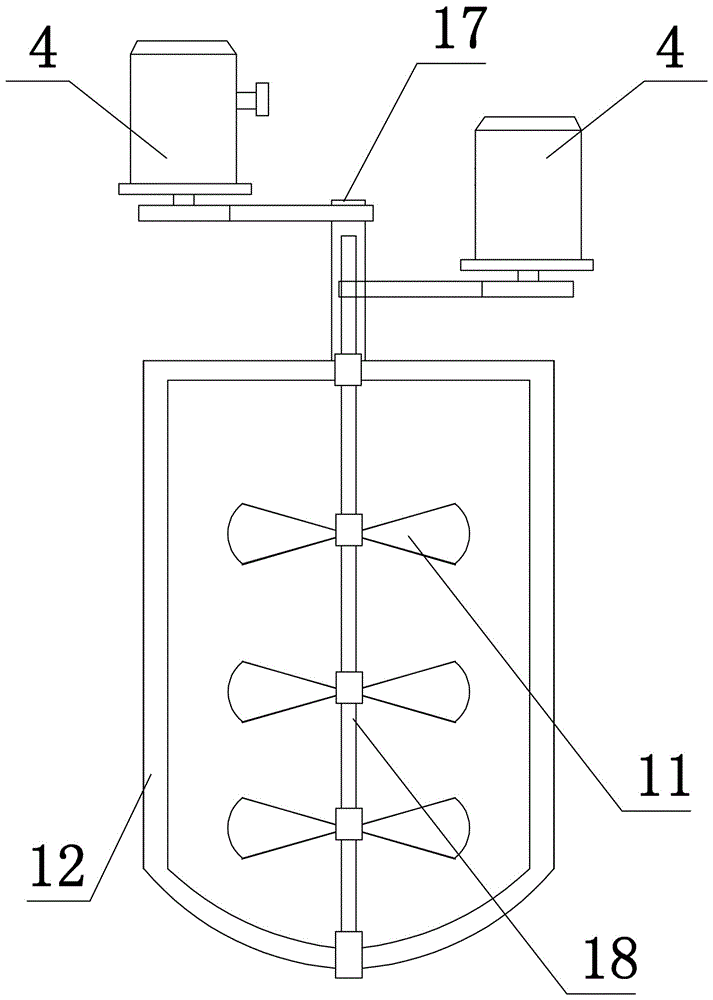

[0030] The present invention includes a tank body 1, a one-way feed valve 2, a one-way discharge valve 3, a stirring paddle, a frequency conversion motor 4, an ultrasonic vibrating rod 5, a vacuum pumping valve 6, a pressure relief valve 7, an additive feed valve 8 and The vacuum gauge 9; the one-way feed valve 2 and the one-way discharge valve 3 are sealed and installed at the bottom of the tank body 1; Including rotating shaft 1 17 and rotating shaft 2 18 which are sealed and socketed, the frame paddle 12 is fixedly connected with rotating shaft 1 17, three inclined blade type paddles 11 are fixedly connected with rotating shaft 2 18, and the upper frame of frame type paddle 12 is located at the uppermost inclined Above the blade type paddle 11, the lower frame of the frame type paddle 12 is located below the lowermost inclined blade type paddle 11; two frequency conversion motors 4 are installed above the tank body, and the upper ends of the first rotating shaft 17 and the s...

Embodiment 3

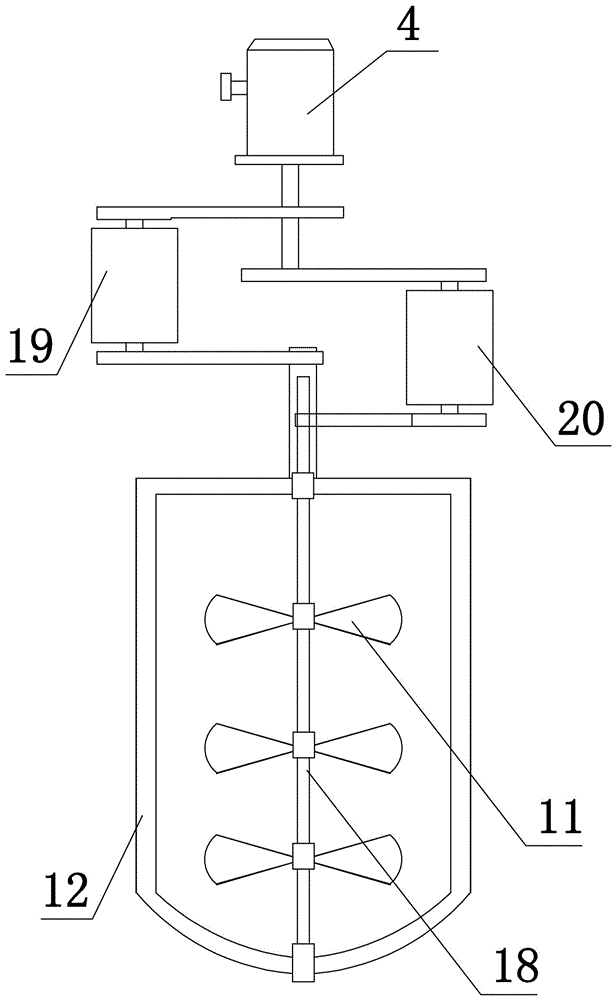

[0033] The structure of this embodiment is basically the same as that of Embodiment 2, the difference is: as image 3 As shown, the frequency conversion motor 4 is one, and a speed reducer 19 can be installed between the frequency conversion motor 4 and the rotating shaft 17, and a speed reducer 20 is installed between the frequency conversion motor 4 and the rotating shaft 2 18, and the speed reducer 19 and the speed reducer The reduction ratio of device two 20 is different, so as to realize the adjustment of the different rotating speeds of the inclined blade type paddle 11 and the frame type paddle 12; as Figure 4 As shown, it is also possible to install a reversing device 21 between the variable frequency motor 4 and the rotating shaft 17, and the reversing device 21 can adopt the steering mechanism or equipment in the prior art to realize the transmission so that the rotation direction of the rotating shaft 17 is the same as that of the rotating shaft 2 18. The direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com