Shell, shell manufacturing method and electronic device

A technology for electronic devices and shells, which is applied in the direction of metal shells, etc., can solve the problems of insufficient connection and insufficient overall strength of the shell, and achieve the effect of enhancing the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

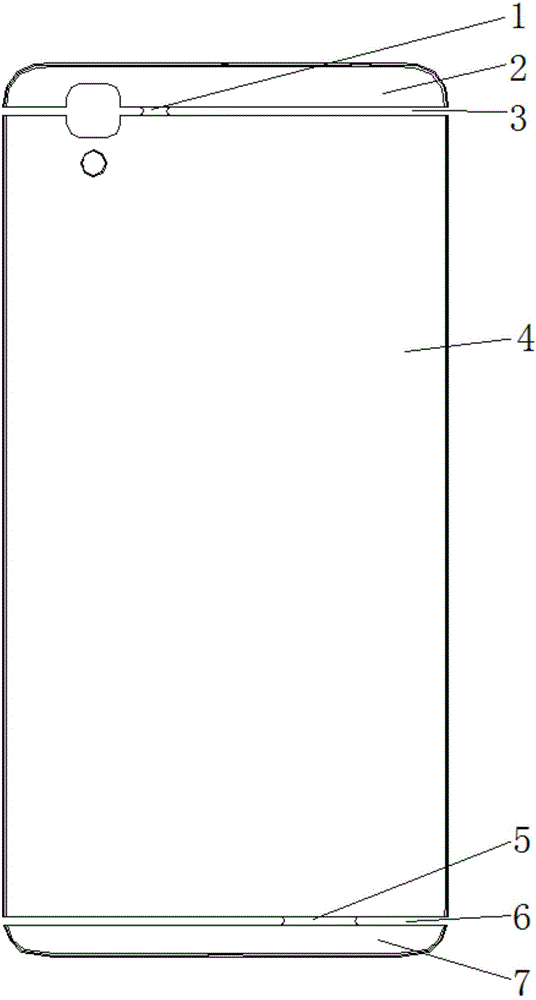

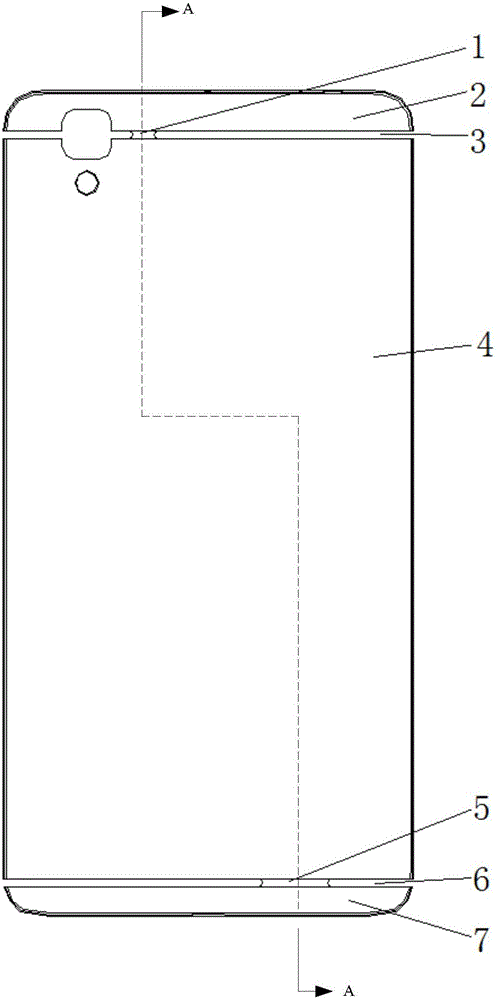

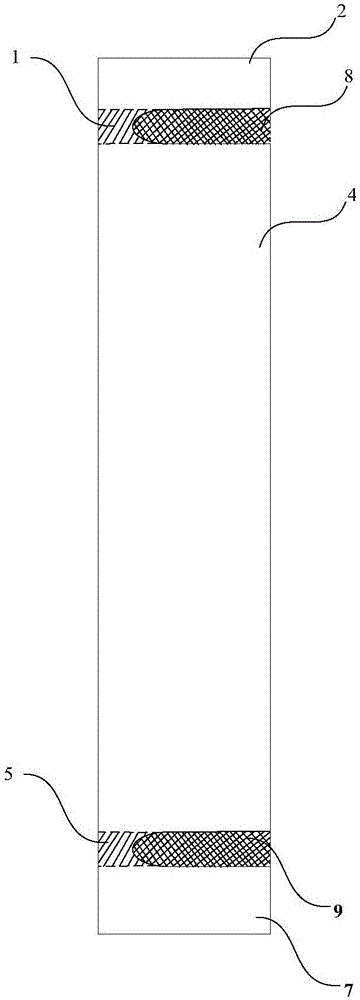

[0035] A casing is provided in an embodiment of the present invention. The casing includes a metal shell and plastic straps. The metal shell is one piece, and the metal shell has a gap and a metal connecting part, and the metal connecting part is integrally formed in the metal shell and is located in the gap. The two ends of the metal connection part are respectively connected to the shell parts of the metal shell on both sides of the gap, and the outer surface of the metal connection part is recessed relative to the outer surfaces of the shell parts on both sides of the gap, that is, the outer surface of the metal connection part and its two sides The shell part of the shell forms a depression, and the inner surface of the metal connection part is recessed relative to the inner surface of the shell parts on both sides of the gap or is flush with the inner faces of the shell parts on both sides of the gap. The plastic tape is filled in the gap, and the plastic tape covers the...

Embodiment 2

[0044] refer to Figure 4 and Figure 5 In this embodiment, the difference from Embodiment 1 is that the first metal connection part 1 is a one-stage metal connection part, and the second metal connection part 5 is a two-stage metal connection part. The one-stage metal connection part is a continuous piece; the two-stage metal connection part includes two spaced apart sub-metal connection parts 51 and 52 located in the same non-signal release area. The length of the one-stage metal connection part is smaller than the length of the two-stage metal connection part, wherein the length of the two-stage metal connection part is the distance between the opposite side edges of the two sub-metal connection parts 51 , 52 . Moreover, the inner surface of the first metal connection part 1 may also be recessed relative to the inner surfaces of the shell parts on both sides of the first slit 3 . The inner surface of the first sub-metal connecting portion 51 may also be recessed relative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com